Last Updated on May 23, 2023 by Tony

Are you a tech enthusiast fascinated by the intricate workings of electronic devices? Or you’re a manufacturer or designer looking to improve your products’ functionality. Precision turning parts may be small, but they pack a punch. They are the building blocks of electronic devices, ensuring their optimal performance. This article will discuss the role of using precision turning parts in electronic devices and how they contribute to their functionality. We’ll also explore some challenges with manufacturing these parts and how manufacturers overcome them. By the end of this article, you’ll better understand the role precision turning parts play in electronic manufacturing. So, grab a coffee and sit back to explore this exciting topic!

What is Precision Turning Parts?

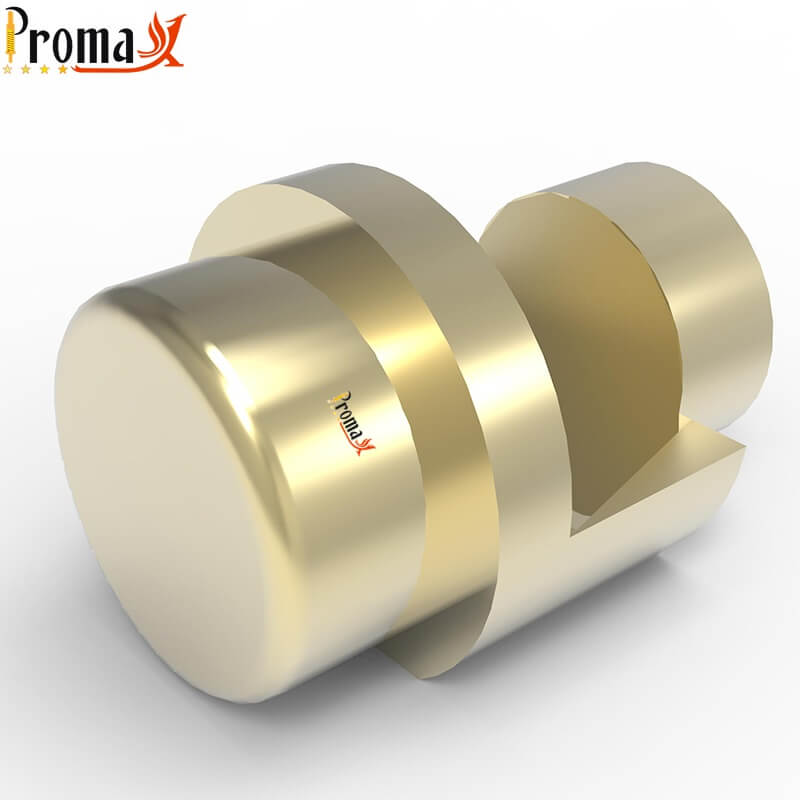

Precision turning parts, the small mechanical components, work accurately and precisely. Made from materials like aluminum, stainless steel, brass, and plastic, they empower various electronic devices. They’re the driving force behind the technology we rely on, from smartphones to medical equipment. It’s incredible to think that something so small can have such a massive impact on our lives.

How are Precision Turning Parts Manufactured?

These incredible mechanical components are made using a cutting-edge computer-controlled CNC machining process. It involves specialized machines programmed with specific designs and dimensions to cut and shape the parts using various tools such as drills, lathes, and mills.

- It starts by creating a 3D part design, which generates the code that controls the machine. From there, the machine expertly crafts the precise parts from raw materials accurately with attention to detail.

- The final product is checked to ensure it meets the required specifications.

It’s a rigorous process that ensures every precision turning part is perfect down to the smallest detail.

The Role of Precision Turning Parts in Electronic Devices

Precision turning parts may not be the stars of the show, but they’re the unsung heroes to keep electronic devices running. They’re like the foundation of a building – without a strong foundation, the building can’t stand. In the same way, if the precision turning parts aren’t accurate or precise, the device won’t work right. So, while being small and hidden, these tiny parts play a critical role in ensuring your device functions the way it should. Precision turning parts are made using cutting-edge manufacturing techniques to ensure they meet the highest quality standards. They should be precisely crafted to fit with components like PCBs and connectors. They create a functional electronic device that can do all sorts of things with other components. Take a smartphone, for instance. It’s made up of many small parts, like buttons, cameras, speakers, and microphones, that all have to fit together. Without precision turning parts, these components wouldn’t fit right, and the phone wouldn’t work seamlessly. Even a small mistake, like a poor connector, could cause the phone to malfunction. So, these tiny parts may seem unimportant, but they’re critical to ensuring your device works perfectly.

Importance of Precision Turning Parts in Electronic Manufacturing

Quality and Reliability

Precision turning parts are designed to fit together with other components in the device with high accuracy. It means there’s less risk of errors, malfunctions, or other issues from parts that don’t fit. Also, the components used in the device are made of superior materials. Thus they provide exceptional durability against deterioration. It guarantees the device’s long-term operability without constant maintenance or substitution. So, with high-quality precision turning parts, you can trust that your device will perform well and last long.

Miniaturization and Weight Reduction

In this modern world, electronic devices are getting smaller and more compact. So, the precision turning parts used to make them should be even more precise and tiny. These parts are made to exact specifications so that manufacturers can create smaller and more compact devices without compromising device performance. Moreover, precision turning parts are usually made from lightweight materials that reduce the weight of electronic devices. This weight reduction makes devices more portable while still ensuring top-notch performance.

Reducing Energy Consumption and Enhancing Performance

Precision turning parts cut friction, reducing energy consumption and heat generation. It is especially crucial in devices with sensitive components, as excess heat can damage these components. Moreover, precision turning parts can operate at high speeds with minimal vibrations. It contributes to the smooth operation of electronic devices and reduces wear and tear on other components, boosting devices’ performance and lifespan.

Precision Turning Parts in Electronic Devices

Types of Precision Turning Parts Used in Electronic Devices

Here are some examples of precision turning parts commonly used in electronic devices:

- Shafts are cylindrical components that transmit power or motion between device parts. They’re often found in motors, pumps, and other mechanical components.

- Screws are used to fasten different components of a device together. They can be made from various materials, including plastic, aluminum, and stainless steel, and come in different sizes and shapes.

- Bushings are cylindrical components that act as spacers or bearings. They help reduce friction between device parts and are often found in moving parts like gears or bearings.

- Connectors, like USBs, HDMI ports, and audio jacks, join different electrical components to transmit data and power.

- Pins, tiny and cylindrical in shape, are crucial components that facilitate connecting various electrical components. You’ll often find them lurking inside PCBs and other electronic components.

Examples of Precision Turning Parts Used in Electronic Devices

- Smartphones are everywhere, and everyone uses them, and you know what makes them so freaking awesome? The precision turning parts inside them! Take the camera module, for example. It has all sorts of cool stuff like lens holders, gears, and shafts to let you focus your shots and get them perfectly stabilized. That’s some next-level precision right there! And then, the speakers have got cones and voice coils to bring you the sound.

- Laptops and other computing devices are also packing many precision turning parts! For example, gears and shafts in the fan assembly keep your device safe from melting into a pile of hot, steaming mess. Also, the hinge mechanism allows your laptop to open and close with the precision of a surgeon’s scalpel. That’s right, precision turning parts are keeping your laptops cool and collected!

- Medical devices like MRI machines and surgical instruments also rely on some precision turning parts to get the job done. Take the MRI machine, for example. It’s got the rotors and stators that allow for next-level magnetic field control. And surgical instruments like forceps, scissors, and clamps have precision turning parts. They give surgeons the power to manipulate tissue with pinpoint accuracy.

Future of Precision Turning Parts in Electronic Manufacturing

The future of precision turning parts in electronic manufacturing is getting spicy hot! With new advancements and trends coming in, things are about to get turned up a notch!

Advancements and Trends in Precision Turning Part Manufacturing

With the power to create highly intricate and customized parts, the future is looking mighty fine. It doesn’t just stop at metal and plastic – we’re talking ceramics and composites too! That’s right, materials that were once too tough for machining are now fair game. We’re breaking boundaries and exploring uncharted territories, all thanks to the wonder of 3D printing. Moreover, forget about human error and slow production rates. With automated manufacturing systems, you can increase production rates and achieve consistency and quality that were once unheard of.

Impact of Advancements in Precision Turning Part Manufacturing on the Electronic Manufacturing Industry

3D printing and automation are paving the way for the production of highly intricate and customized parts at a lower cost. It means more innovation and competition, baby! It’s all about pushing the boundaries and creating cutting-edge technology that will blow your mind. With advanced manufacturing techniques come highly accurate and precise parts. It means the development of more sophisticated and high-performance electronic devices, including emerging technologies like IoT, 5G, and AI. These technologies rely on highly precise and reliable components to operate effectively. And with advancements in precision turning part manufacturing, you can create the components to keep these technologies running.

Potential Applications of Precision Turning Parts in Emerging Technologies

The potential applications of precision turning parts in emerging technologies are mind-boggling! Let’s take IoT devices, where precision turning parts are essential in manufacturing sensors. These parts enable accurate and reliable data collection. IoT devices need to operate effectively. In 5G technology, precision turning parts can be used in manufacturing antennas and waveguides. These parts allow for high-speed data transfer rates, which is crucial for the success of 5G technology. And also, AI technology, where precision turning parts can be used in manufacturing robotic components. These parts enable high-precision movement and manipulation, which is essential for the success of AI technology. It’s all about creating machines that can think and act like humans, and precision turning parts are taking a part in making it all possible.

Conclusion

From the tiniest gears in watches to the complex connectors in smartphones, precision-turning parts are the backbone of the tech-driven world. They are the very foundation of electronic devices. They ensure reliability, functionality, and performance with absolute precision and accuracy. Without them, we’d still be lugging around clunky and inefficient devices that barely function. So whether you’re a manufacturer or a tech enthusiast, it’s time to give these parts the recognition they deserve. Next time you use your trusty smartphone or computer, take a moment to appreciate the precision-turning parts that make it all possible.