High Current Pogo Pin Connector

Are you looking for the High Current Pogo Pin Connector of the right size? are you greatly worried about how to find high-quality products, the shortest delivery time, the lowest cost, and optimal services? Dongguan Promax is a professional pogo pin connector ODM Factory & Manufacturer since 2014, we believe we can provide you with the best solutions & perfect products, looking forward to win-win cooperation!

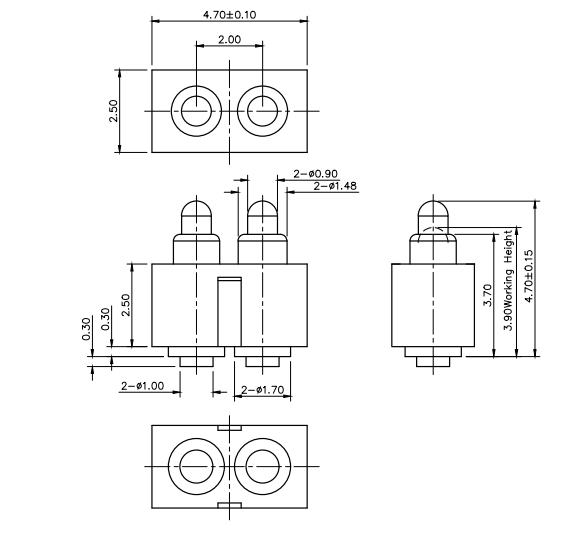

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

DIP, SMT/SMD, solder cup, screw thread, or others

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Use Case of High Current Pogo Pin Connector

This case was about a high current pogo pin connector used in a TWS Bluetooth headset charger from the famous Huawei company. To meet the needs of customers, our connector will be used in this Bluetooth headset charging base. It plays the role of fast charging in headphones and shortens charging time.

Since this TWS Bluetooth headset has the characteristics of miniaturization, the high current pogo pin connector we need to provide must be of high precision. Read More ReadLess

Our R&D Team Who Focused on The Product

Our R & D team has very rich experience in connector design, and we have formed strategic partners with Huawei, Xiaomi, and other well-known brands. If you need a custom design, our R & D team can do it. Read More ReadLess

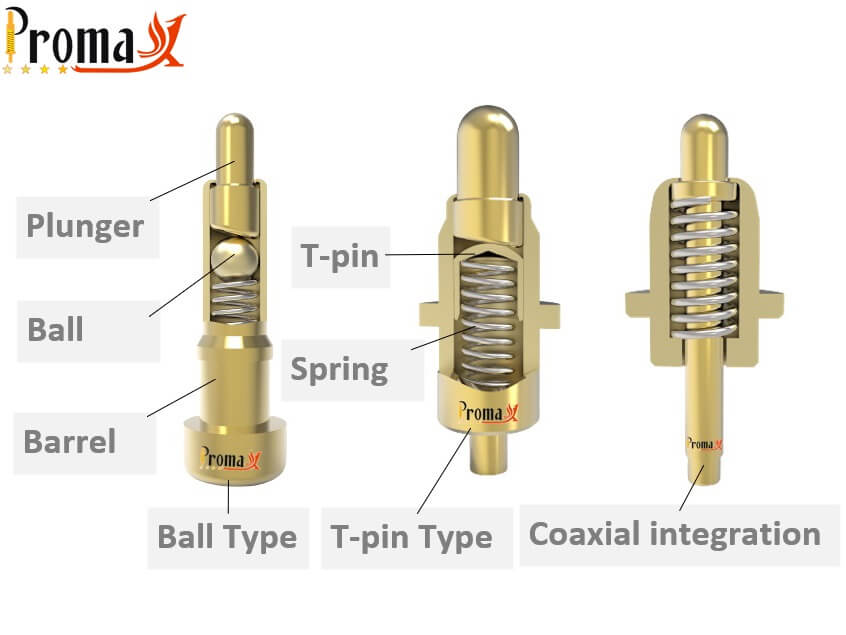

What is The Structure of a High Current Pogo Pin Connector?

The structure of the high current pogo pin is different from other pogo pins. The commonly used pogo pin structure does not meet the use of a large current, which is easy to cause short circuits. Read More ReadLess

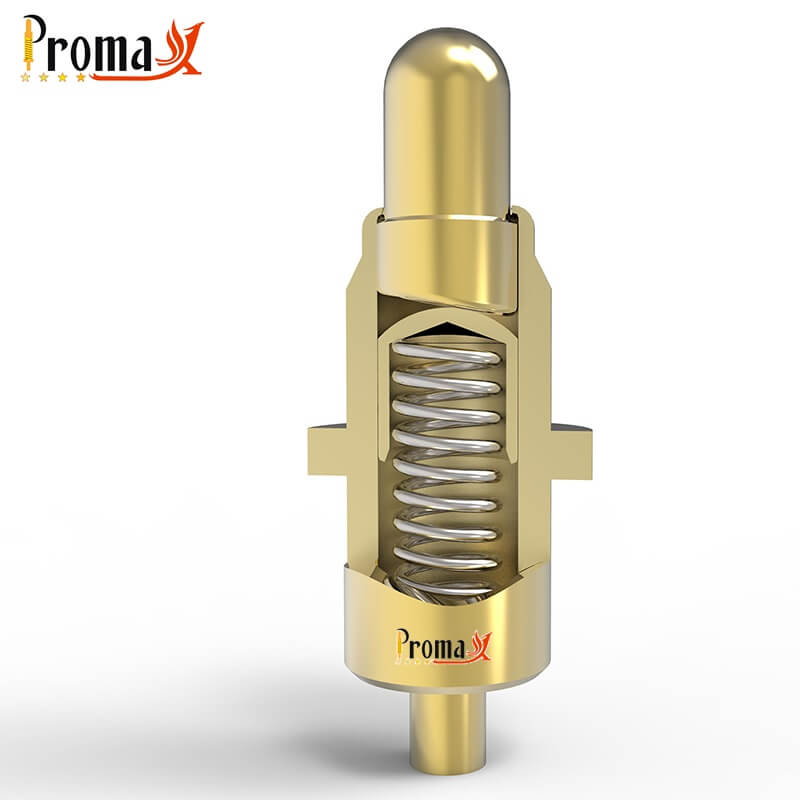

What is Its Structure of Coaxial Integration?

Coaxial integrated structure: The plunger part of the pogo pin is a structure through spring and needle pipe. It keeps the simple structure of the pogo pin and effectively reduces the resistance. Read More ReadLess

What Are The Materials and Plating?

| CATEGORY | High Current Pogo Pins | |

| Sub-parts | Plunger | Brass, SUS304, SUS316F, SUS316L, CuTe, BeCu, FeN,stainless steel 904L, High carbon steel, etc |

| Barrel | ||

| Spring | SUS304, SUS301, Beryllium copper cable, FMW1508, Nonmagnetic Spring, insulation Spring, etc | |

| Ball | Brass, SUS304, Zirconium ball, Alumina magnetic ball, etc | |

| Plating | Au, Ag, PD, Rh-Ru, Ni, etc (2~200 U” over 30~150 U” Ni) | |

T-pin type design: The T-pin structure adds a cover between the plunger and the spring, Read More ReadLess

Ball-type design: The ball structure adds a ball between the plunger and the spring, Read More ReadLess

What are The Advantages of a High Current Pogo Pin Connector?

When you need to transfer a lot of power quickly and reliably, a high current pogo pin connector is the answer. These connectors can handle currents up to 15 amps, making them perfect for applications like battery charging or motor control. They are also very reliable, with a lifespan of up to 10,000 cycles.

How to Choose the Right One?

When you choose a high current pogo pin connector, it is important to consider your application. For example, you need a 5A connector to meet your PCB, and you need to consider its shape and function to meet your needs. Read More ReadLess