PCB Pins

Are you looking for the PCB Pins of the right size? are you greatly worried about high product quality, the shortest delivery time, the lowest cost, and optimal service? Dongguan Promax is the best, as a professional ODM Factory & Manufacturer since 2014, we believe we can provide you with the best solutions & perfect products, looking forward to win-win cooperation!

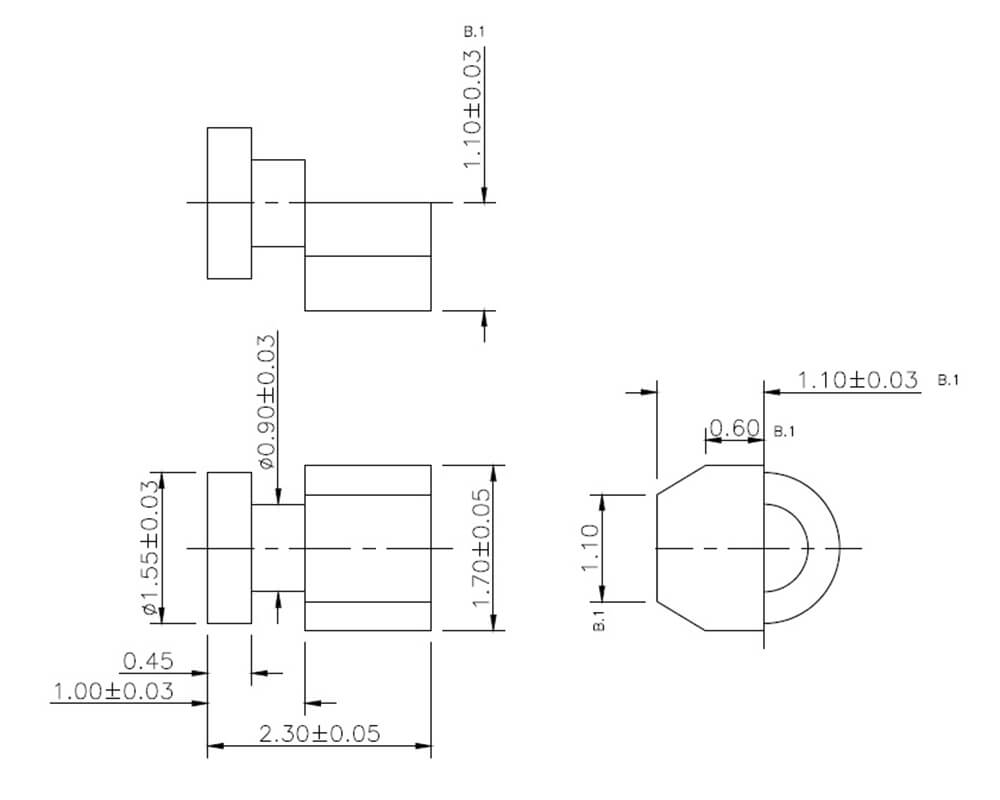

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm

SHAPE

Any, whatever

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Use Case of the PCB Pins

This case described the design of a precision turning part used for a TWS Bluetooth headset from a famous TWS domestic company QCY Group, product requirement was to comply with all environmental protection requirements about RoHS2.0, REACH, H/F.

It was a side-mounted solid precision turning part, which was the charging on the Bluetooth headset to transfer the current. Its material was lead-free brass, the coating was 4U” Au.

Studied Customer Requirements

Our engineer double-confirmed with the customer about complete product requirements, application, and environmental protective details, and then, we internally discussed how to effectively eliminate all potential risks of the product. it was the structure of the right-angle type. the material of the precision turning part was lead-free brass, its cost was Au 4U” min over 50-120U” Ni.

The PCB Pin was processed by high precision CNC lathe based on the customers’ actual requirements, so, its cosmetic shape was varied and very complex, such as internal and external cylindrical surfaces, internal and external conical surfaces, end faces, grooves, threads, forming surfaces, and so on.

What is the material for the PCB Pin?

Brass is the ideal material for brass precision-turned components. Brass have low weight and high strength characteristics and can be precision machined to customer specifications. It also has excellent electrical conductivity and good corrosion resistance. Read More ReadLess

Machining Process of PCB Pins:

The process of turning can be divided into three steps: turning, polishing, and electroplating.

- First, the material is cut out of the desired shape using a CNC machine, usually leaving an error of 0.01 mm.

- Secondly, polishing is carried out to polish the PCB Pins to the required surface finish.

- Finally, the electroplating material and film thickness are selected according to their function.

Read More ReadLess

What are The Characteristics of It?

Substantial reduction in the number of parts and processing of complex-shaped PCB Pins without the need for multiple parts to be used with each other. Stable processing quality and high precision can adapt to the processing requirements of flying chess.

Read More

ReadLess

Application of PCB Pins

The shape of PCB Pins is complex and suitable for various high-precision equipment. For example, computers, mobile phones, electronic cigarettes, and other consumer electronics.

Read More

ReadLess

How to Choose The Right One?

It is important to select a qualified precision turning part. You need to choose from the precision after processing, usually qualified turning parts error will be 0.02 mm.

Read More

ReadLess

Why Dongguan Promax?

When it comes to precision machining, few companies can match the level of skill and expertise exhibited by Dongguan Promax. With over 15 years of experience in the field, Dongguan Promax has perfected the art of small turning parts with extreme accuracy and precision. No other company can provide the same level of quality and reliability when it comes to precision turning parts. Dongguan Promax is a trustworthy PCB Pins manufacturer.