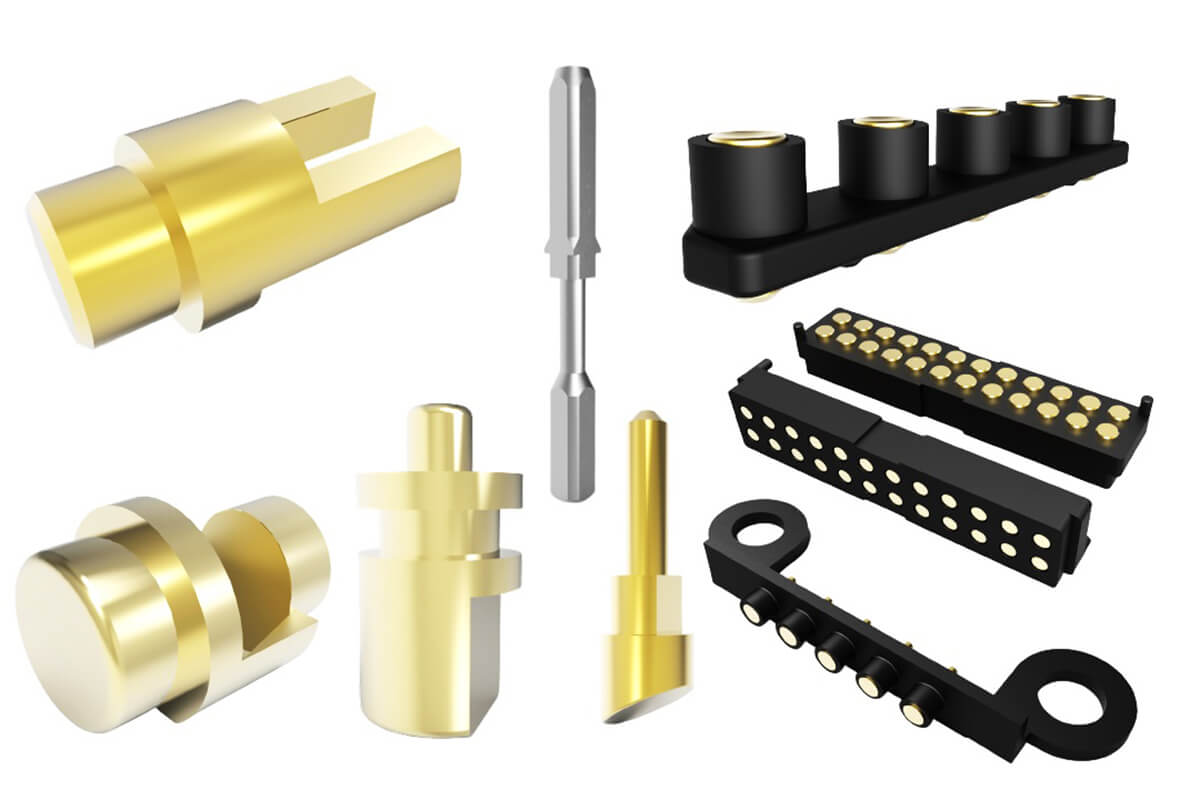

Best PCB Pins Manufacturer & Supplier

Are you looking for PCB pins manufacturers with competitive prices? Are you still looking for high-precision PCB pins manufacturers? Dongguan Promax can provide not only high-precision PCB pin but also competitive prices, not only to complete the delivery on time and volume.

As a professional Manufacturer & Supplier. Already provided customers with >2000 kinds of productsIncluding Single Pin and Connector. Almost 400 precision CNC lathes, daily capacity of 5,000,000 single parts, mass production FPY >99% (FPY: First Pass Yield)

Safe & On-Time Delivery

Leave your requirements and let Dongguan Promax handle the rest.

24/7 Online Support

Dongguan Promax is always here to support your business.

Competitive Price

Get better shipping rates to reduce your costs.

After the PCB pin is produced from the CNC machine, it will be sent to be cleaned. Finally sent to the clean workshop.

This will be followed by CCD, aligner, manual pressure, crimping, and full inspection. A PCB pin has multiple testing steps to ensure that each PCB Pin is of high quality.

FAQ

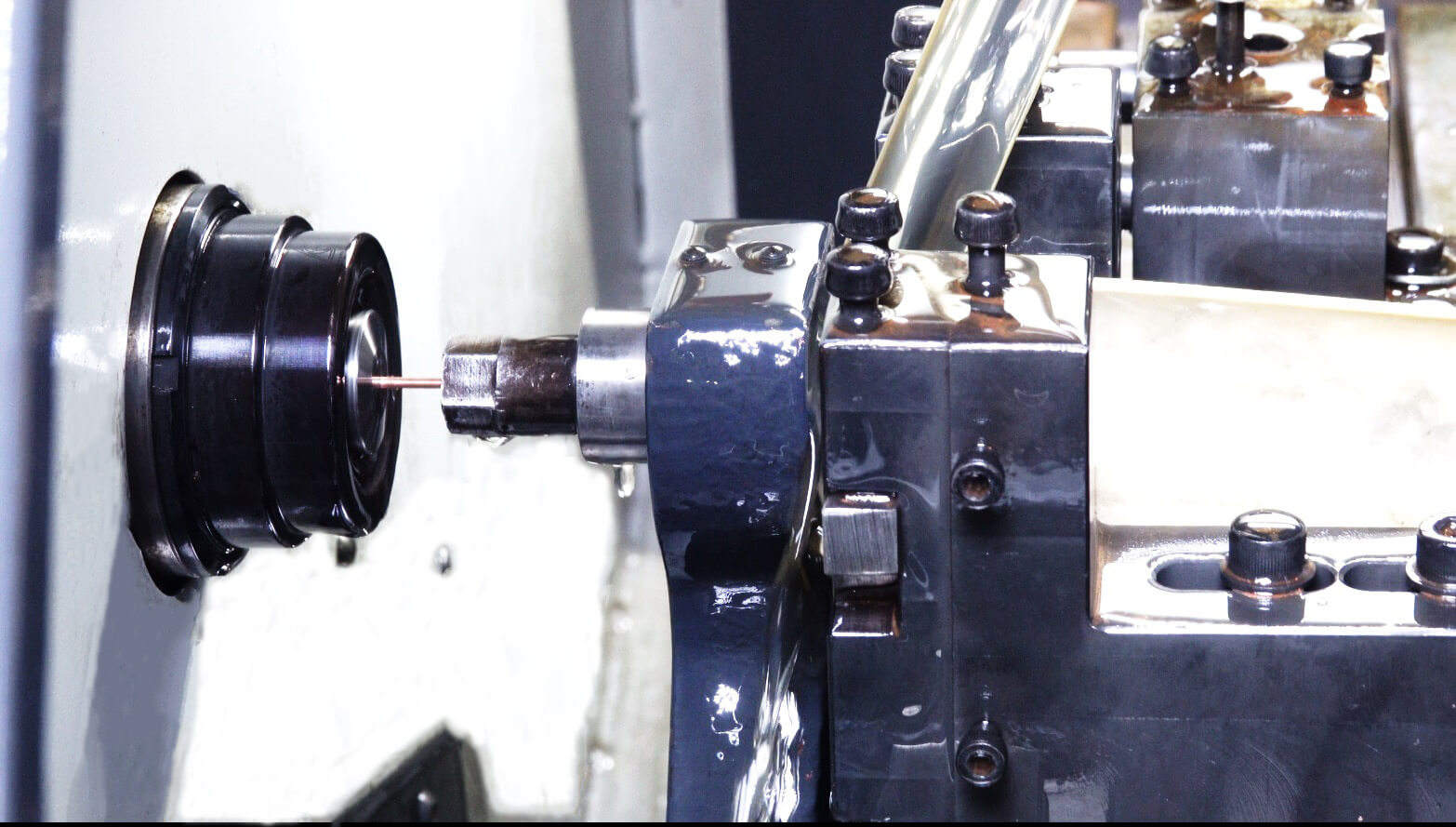

Turning is a method of cutting a workpiece on a lathe by rotating the workpiece to the tool. Most workpieces with rotating surfaces can be processed by CNC turning, such as internal and external cylindrical surfaces, internal and external conical surfaces, end faces, grooves, threads, forming surfaces, etc.As a custom PCB pins manufacturer.

Dongguan Promax adopts the lathe tool imported from Germany, which greatly improves the manufacturing efficiency of PCB pins and reduces the cost of customizing turning parts. Dongguan Promax has been made with efficient PCB pins. Precision PCB pins technology and competitive PCB pins price has won the trust of global customers.

CNC machine tool is an important tool for human production and labor, but also an important symbol of social development level.

Its development has gone through many years, from the initial manual operation, simple mechanical processing gradually developed to semi-automatic, automation until today’s most new machine tools – CNC machine tools.

CNC machine tools are controlled by numerical control technology, which is a typical mechatronic product that comprehensively applies advanced technologies such as computer technology, automatic control technology, precision measurement technology, and machine tool design, and is the foundation of modern manufacturing technology.

- CNC machining can obtain higher precision and stable quality.

- High processing efficiency.CNC machine tools have good structural rigidity, allowing strong cutting with large cutting parameters, which improves cutting efficiency and saves motor time. Its moving parts move fast in empty stroke, the workpiece clamping time is short, the tool automatic replacement, auxiliary time is greatly reduced than the general machine tool. In the machining center, a machine tool realizes the continuous processing of multiple processes, and the improvement of production efficiency is more obvious.

- The high degree of automation can greatly reduce the labor intensity of workers.

- It has good adaptability and flexibility for parts processing.

- A multi-purpose machine has good economic benefits.

- Multi-coordinate linkage can be carried out to process parts with complex shapes.

- Ability to process complex workpiece surfaces that are difficult or impossible to process by hand.

CNC turning is one of the most widely used machining methods in CNC machining.

Because the CNC lathe has the characteristics of high precision, linear and circular interpolation, and automatic speed change in the machining process, its process range is much wider than ordinary machine tools.

CNC lathe is suitable for turning rotary parts with the following requirements and characteristics.

- Rotary parts with high accuracy requirements

- Rotary parts with special thread

- Rotary parts with complex surface shape

- Other parts with complex shapes

- Small turned parts, suitable for developing new models or modifying, minimized assembly, shorten delivery time

- Stable CNC machining quality, high machining accuracy, high repeat accuracy

- Because the best cutting, greatly shortens the cutting time, so, very high production efficiency, especially in tight lead time and low volume

- Easy to machine complex surface

| Main Materials | |

| Aluminum | AI6061,AI6063,AI6082,AI7075,AI2024,AI5052,A380,etc. |

| Stainless Steel | SS201,SS301,SS303,SS304,SS316,SS416,etc. |

| Steel | Mild Steel,Carbon Steel,4140,4340,Q235,Q3458,20#,45#,etc. |

| Brass | C35600,C36000,C37000,C37700,C37100,C28000,C26000,C24000,C22000,etc. |

| Copper | C11000,C12000,C12200,C10100,etc. |

| Iron | 20#,45#,Q235,Q345,Q3458,1214,12L14,1215,etc. |

| Plastic | POM,Peek,PMMA,ABS,Delrin,Nylon,PVC,PP,PC,etc. |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating. etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized,Color Anodized,Sandblast Anodized,Chemical Film,Brushing,Polishing,Power Coated,Nickel Plated,etc. |

| Plastic | Plating gold(ABS),Painting,Brushing(Acylic),aser engraving |

- Customers’ requirements, we can meet targets, because of a strong R&D team and 400 CNC lathes

- Operating and Training according to ISO9001, ISO14001, QC08000

- Daily capacity 5 million finished goods

- Fully customized without based cost added

- Ensure the shortest delivery time via FedEx, DHL, UPS

PCB pins, widely apply to the field of consumer electronics, new energy, chipset test, communication, security, smart home, medical, entertainment, retail, personal, industry, for example TWS, mobile, e-cigarette, smartwatch, smart wear, phone, and so on