High Current Pogo Pin

Are you hoping for high current pogo pins of the appropriate size? are you care about the delivery time and product unit price? Dongguan Promax is a professional pogo pin ODM factory & supplier of pogo pins since 2014, we are strongly confident in working up your questions and absolutely accomplish your expectation!

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

DIP, SMT/SMD, solder cup, screw thread, or others

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Use Case of High Current Pogo Pins

The case was about the requirements of 2 customers (HUAWEI, XIAOMI) in 2020, who sought a high current pogo pin for an electronic cigarette and asked to provide the product with 12VDC, 5A current. shipment capacity was more than 500K per day, process capacity was up to 4 Sigma, that is, the pass rate was more than 99.62%.

Our R&D Team Who Focused on The Product

After receiving customers’ requirements, we studied the product requirements together. we were sure we could do it based on our R&D experience, furtherly, we worked out DFM & DFMEA to confirm every detail no risks on process manufacturing and technological process, including preliminary quality SIP and process SOP, and so on. Finally, a high current pogo pin with coaxial integration was commended.

Read More

ReadLess

Product Design

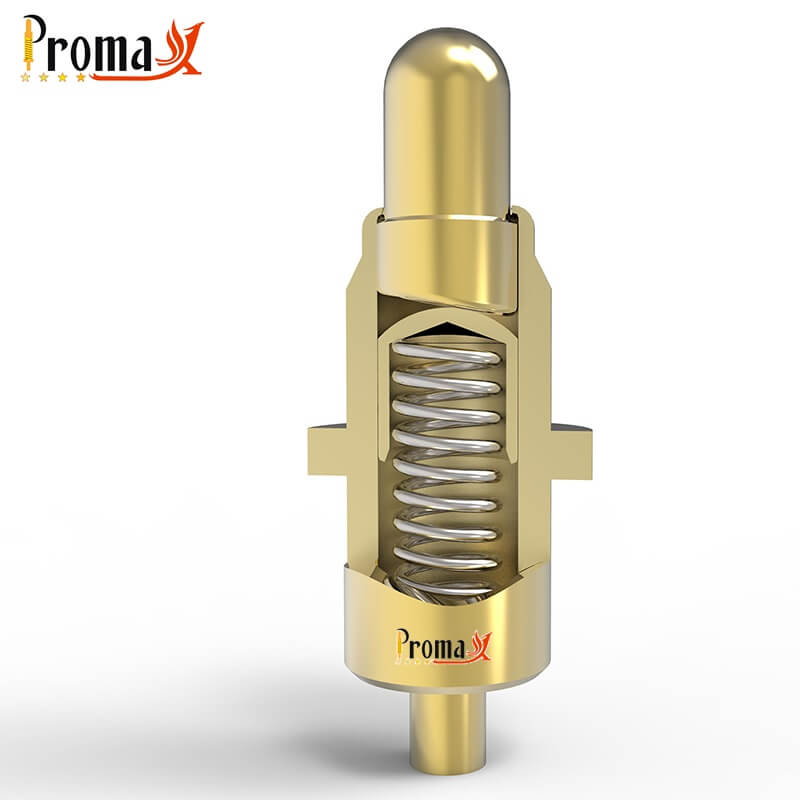

The structure of coaxial integration high current pogo pin, full stroke was 1.3mm, work stroke was 0.90mm, spring force was 68gf±15%gf at working height, rated voltage DC12V, rated current 5A, the material of the plunger and barrel was HBi59-1.5, Read More ReadLess

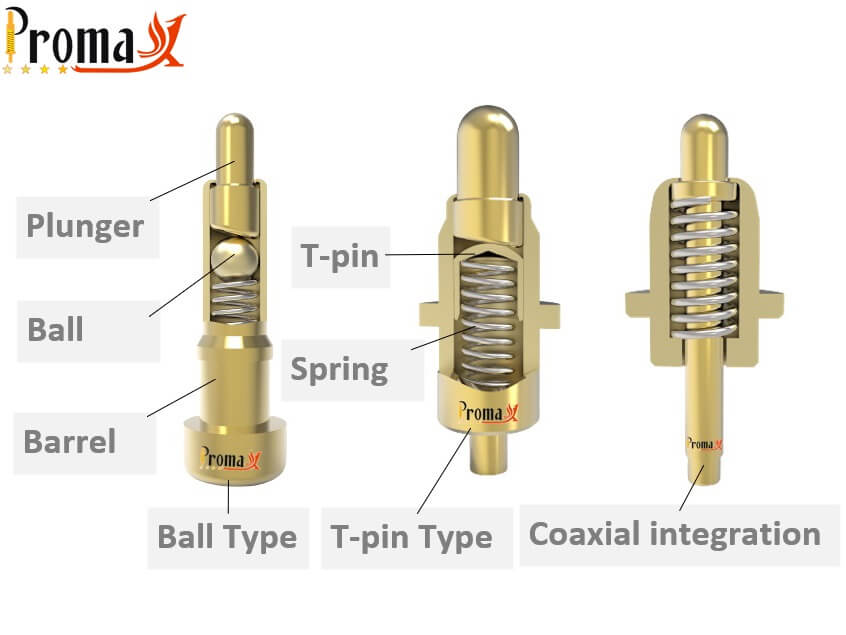

What is The Structure of High Current Pogo Pins?

It has a different structure from other pogo pins. The usual three parts of the pogo pin do not meet the requirements for high current use, its structure is not enough to support the passage of high current, easy to form a short circuit.

Read More

show less

What is Its Structure of Coaxial Integration?

Coaxial integrated structure: The plunger part of the pogo pin is a structure through spring and needle pipe. It keeps the simple structure of the pogo pin and effectively reduces the resistance.

Read More

ReadLess

What are The Materials and Plating?

| CATEGORY | High Current Pogo Pins | |

| Sub-parts | Plunger | Brass, SUS304, SUS316F, SUS316L, CuTe, BeCu, FeN,stainless steel 904L, High carbon steel, etc |

| Barrel | ||

| Spring | SUS304, SUS301, Beryllium copper cable, FMW1508, Nonmagnetic Spring, insulation Spring, etc | |

| Ball | Brass, SUS304, Zirconium ball, Alumina magnetic ball, etc | |

| Plating | Au, Ag, PD, Rh-Ru, Ni, etc (2~200 U” over 30~150 U” Ni) | |

T-pin type design: The T-pin structure adds a cover between the plunger and the spring,

Read More

ReadLess

Ball-type design: The ball structure adds a ball between the plunger and the spring,

Read More

ReadLess

What are The Advantage of High Current Pogo Pins?

Stable contact resistance: It is mainly used in the intelligent terminal equipment, so it has high requirements for the stability of the current signal.

Life cycle: It needs to be inserted and removed repeatedly during operation, and its life cycle can reach 100,000 times.

Read More

Small size, high density, lightweight: With the continuous development of science and technology, intelligent equipment tends to be miniaturized and diversified. Therefore high current pogo pin size and accuracy requirements are particularly high.

Easy to update: With the continuous progress of technology, it can also update its components when installing a high current pogo pin. At the same time, better components can be used to replace them.

ReadLess