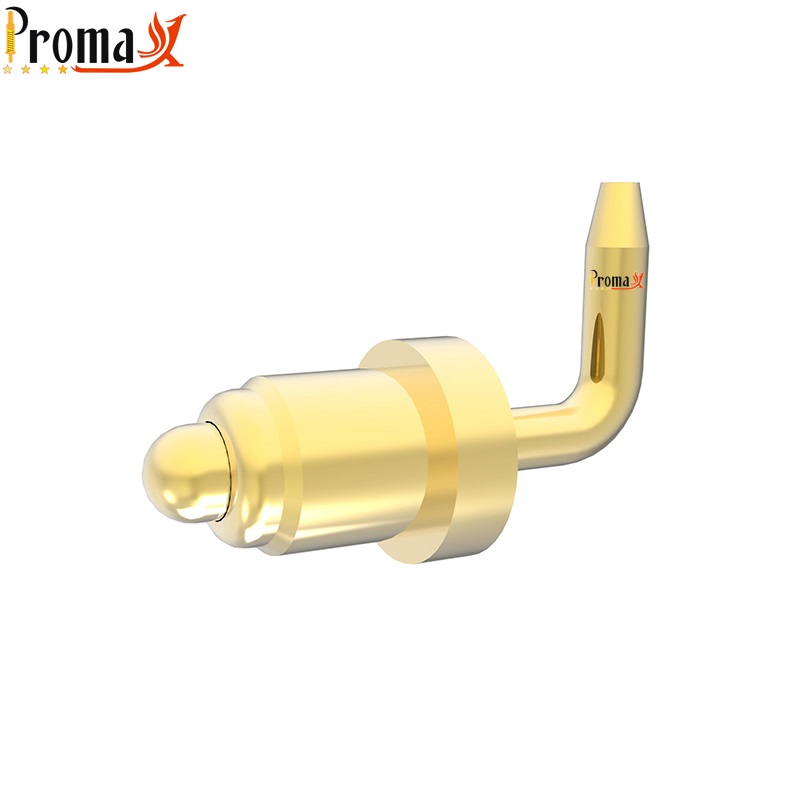

Bending Type Pogo Pin

Are you finding Bending type pogo pins of the most accurate size? are you eager to get a high-quality product, with the shortest delivery date, and a Competitive price? Dongguan Promax, a professional pogo pins ODM Manufacturer & Vendor since 2014, we are confident in providing you with the best proposal and technical solutions, fixing your issues, and meeting your targets!

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

Bending type, with a tail pin, or others

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Use Case of Bending Type Pogo Pin

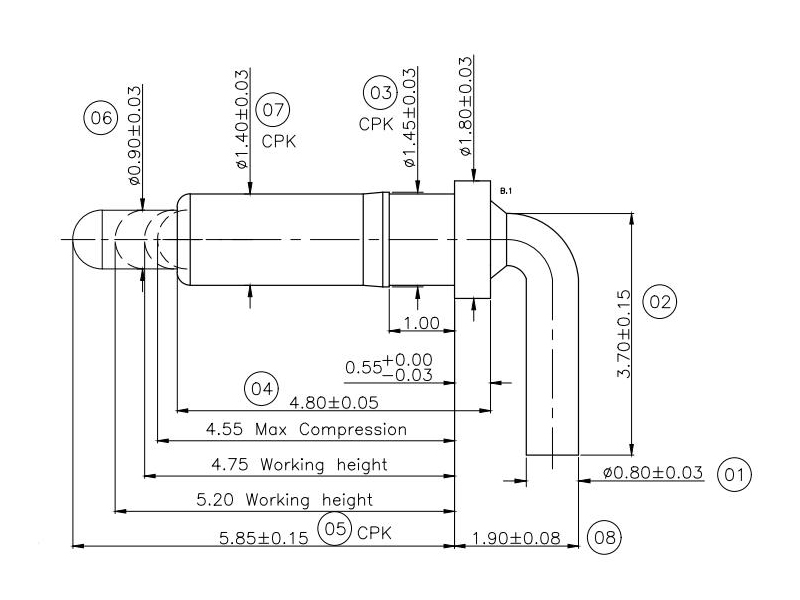

The Case of electronics cigarettes was one of the pretty many projects from a large manufacturer ChengBiao Company, requests as below:

- No chamfer C0.2, surface roughness Ra0.8

- Material, plunger/barrel was HBi59-1.5, Spring was SUS304,

- Plating: plunger 10″ Au, barrel 4u” Au,

- Rated voltage/current, 4.2VDC, 4A,

- Spring force, 62.5g±7.5g,

- Life cycle, more than 10,000 times.

Our R&D Engineer’s Designs

Based on the 4A current required by the customer, our preliminary proposal is to adopt the structure of the ball type, and the spring within the pogo pin must be insulated. according to the accurate shape of the electronic cigarette, the bending type pogo pin was recommended. Read More ReadLess

Case Results

We detailedly designed product drawings, manufacturing technology processes, quality control processes, and so on, and all met customers’ targets including 4 Sigma with 99.62% FPY, daily capacity with more than 500,000 pcs per working day, etc. Read More ReadLess

Why the Bending type pogo pin is the best solution?

When the customer’s order quantity is relatively small, the cost of a customized stamping mold is relatively high. Because of the low cost of production materials, the bent Pogo pin has a simple structure and is easy to process. You can choose pogo pin connectors with low cost to meet production needs and reduce production costs.

What is the Material of Bending Type Pogo Pin?

Plungers and barres commonly used metal materials are:

- Brass: C3604,C3601,C2680;

- Phosphor Bronze: C5210, C5191, C5440;

- Beryllium Copper: C17200, C17300;

- Tellurium Copper: C14500;

- SUS304, SUS316F, SUS316L.

The main considerations for selecting the materials commonly used for Plunger and Barres are:

- Hardness and cutting performance;

- Electrical conductivity; Yield strength;

- Ductility; Material cost;

- Corrosion resistance and environmental performance;

Spring commonly used metal materials are:

- SUS304;

- SUS301;

- BeCu;

- Phosphor bronze;

- No magnetic spring

The main considerations for selecting common spring materials are:

- Wire diameter and overall size;

- Elasticity and life;

- Corrosion resistance and high-temperature resistance;

- Material cost;

- Environmental performance

Why the Bending type pogo pin is the best solution?

When the customer’s order quantity is relatively small, the cost of a customized stamping mold is relatively high. Because of the low cost of production materials, the bent Pogo pin has a simple structure and is easy to process. You can choose pogo pin connectors with low cost to meet production needs and reduce production costs.