Best Pogo Test Pin Manufacturer & Supplier

Dongguan Promax manufactures different pogo pins-related products, including ATE, ICT, FCT, precision probe sockets, Semiconductor probes, and BGA probes.

Our products are superior in quality and meet all the tiny pitch test criteria and performance.We’re responsible for their excellent lifespan with longevity.

It is commonly used in mobile phones, automobiles, laptops, GPS navigation, and other accessories. Dongguan Promax is a pogo pin supplier that has cleared all the precision, small pitch, and chipset tests.

On-Time Delivery

Share the requirements and get the high-quality pogo test pin on time.

24/7 Online Support

Boost your business and sales with Dongguan Promax’s 24/7 online support

Competitive Price

We offer guaranteed competitive prices across the town, making us the best.

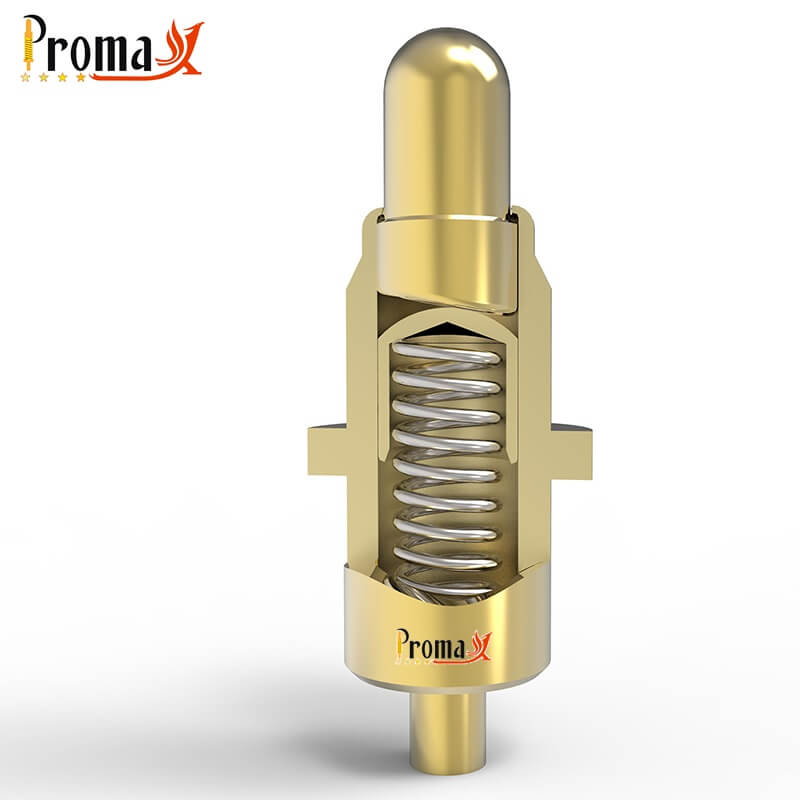

Pogo Test Pin

FAQ

Pogo pins are small that are very handy for making fixtures or momentary (but electrically solid) contacts. It is mainly used to connect conductive and propagative signals.

PCB Pogo pins have a high power of programming and testing fixtures, but they’re handy; if you want to JTAG program a board, you can’t solder the headers. The main advantage of the pogo test pin is contact reliability.

It is perfect for contact reliability, small insertion loss, long working life, and stable performance.

The pogo pin connector has a significant amount of compression and a more stable contact than the shrapnel connector of the same size.

When an external force strongly impacts it, the spring pressure of the pogo pin connector changes relatively small. It can effectively save PCB board space with a relatively higher precision rate.

Other than the general chip testing process. Pogo pin connector is also widely used in the mobile phone market. The connector is one of the essential components in mobile phones, tablets, and automobiles. It is also used in externally connected I/O connectors, sim card connectors, batteries, and camera sockets.

The quality of the pogo pin depends on what material it is made of, along with the coating material, casing diameter accuracy, and its structure and production process.

The pogo pin plays the role of connecting the circuit; the basic structure of its single-pin connector consists of three parts: Plunger (needle), Spring / Tube (spring), and Body (main needle).

In the connector industry, the pogo pin is a unique product with high precision. In terms of composition, the mouth of the needle tube is crimped to keep the needle head in the needle tube, and the contact force is provided by the spring that makes an electrical connection between the needle head and the butting part.

The pogo test pin works excellently to connect two different pieces of circuits.

Whether it is a connection between two Printed Circuit Boards (PCB) or just between a part of the circuit card and any other outside element, it quickly tests the capability of a circuit and screens out the faulty aspects of a course to minimize the wastage of subsequent finished products.

The working principle of the PCB pogo pin is to send signals regarding the functioning of the component to which it is attached in the circuit.

The signals are fed to the test system to check for accuracy. If the test signals are accurate enough, they ensure the proper working of tested equipment; if not, the equipment may be faulty.

The test system simultaneously identifies all the tests regarding the selected equipment, which it passes and fails.

Diversification and Customization

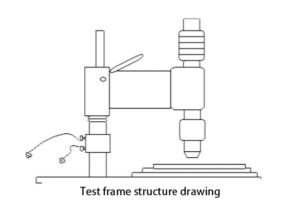

- Diversification and customization material inspection, metal coating, CNC machining, design control, size analysis, assembly, function test, impedance test, instant off test, packaging, and so on.

- Dongguan Promax has constantly developed pogo pin probes and precision probe sockets to maintain consumers’ interest.

-

Strict Quality Control

- We efficiently maintain product quality with a >99% FPY(First pass yield)

- We prioritize our customers and work on the zero-defect rule.

-

Satisfactory service

- We provide international sales and application engineers with full-time support.

- We ensure a pre-sales and post-sales service of high-quality pogo spring test probes.

- 24/7 customer service care

The reliable connection technology of the pogo test pin is widely used in wearable devices, smart positioning devices, children’s smart bracelets, smart watches, wearable mobile phones, Bluetooth headsets, etc., data cables, charging cables, and magnetic suction board wire end connectors.

The mating end of the contract is usually gold-plated and is usually a sharp point. The connection is made when this sharp point is pressed against the usually softer “mating contact,” which transmits signals and conducts current.

These pogo probes come in different varieties according to their head types. These probes deal with varying test points such as flat head, sawtooth, and tip.

With the rapid development of science and technology, the electronic industry extends more and more products. Different types of products are tested in different ways, and pogo test pins are divided into different types according to different functions.

- ICT probe: generally diameter between 2.54mm-1.27mm, the industry-standard name: 100mil, 75mil, 50mil, mainly used for online circuit testing and functional testing. Also known as the ICT test and FCT test. It is also a probe widely used at present.

- Interface probe: Non-standard probe is generally made for a small number of customers who do large test rigs. It is used to test the contact point and surface of the test rig and the test fixture.

- Switch probe: a single switch probe has two currents;

- High-frequency probe: Used to test high-frequency signals, with a shielding ring can be tested within 10 GHz and 500 MHz without a shielding ring.

What is the classification of the pogo test pin according to functionalities?The current electrical goods need a tool to rectify the circuit and its problems. They are emerging towards the trend of simplified installation and refinement, along with a long maintenance life.

The pogo spring test probe connector is small and has a telescopic design, which can well meet the needs of current electronic and electrical products. Different types of pogo test pins are classified according to their functionalities.

- ICT probe

In-circuit Test Probe is practical for checking individual components of an assembly. It quickly detects the faulty components to eliminate them from the circuit. Hence, the function test (FCT) is used to check the electrical behavior of the circuit.

- Interface probe

Interface pogo probes have a unique design to test the contact point and surface of the test fixtures. It is common working equipment for customers who want to frequently try the test rigs and fixtures or have large test rigs.

- Switch probe

A switch probe verifies the presence of connectors or components in the circuit—the current flow in the probe from two separate paths to detect the presence of any non-conductive element.

- High-frequency probe

It has a great capacity to test high-frequency signals. It serves as an ideal port-extending component in a circuit or network analyzer. It can measure up to 500 MHz of frequency signal without a shielding ring.

- Rotating probe

Rotating probes have mechanical devices to turn and insert the probe into the hole. It is an alternative for the testing of assembled elements across the circuit. It is generally used for PCBA tests.

- High current probe

Because of their jagged design, high-current probes have an extraordinary capacity to measure high current in the circuit. It can withstand a current range of 3 to 150 amps and beyond.

- Double Ended Probe

Varies in dimension as the dimension is not fixed.

- Battery probes

Whenever there is a circuit that has mixed power and data application, then battery probes are an excellent option. They have high insertion life and high system tolerance capability.

- Wire harness probe

It is mainly used in the production fields of motor-related products such as motorboats, automobiles, and other electric vehicles, where a wire harness test is one of the main steps of production.

- General purpose probes

The general-purpose probes are used for industrial purposes. They are permanently attached to an element to be tested, which can’t be replaced without damaging the component. It is connected inside the product where replacement is impossible.

| Main Materials | |

| Aluminum | AI6061,AI6063,AI6082,AI7075,AI2024,AI5052,A380,etc. |

| Stainless Steel | SS201,SS301,SS303,SS304,SS316,SS416,etc. |

| Steel | Mild Steel, Carbon Steel,4140,4340, Q235, Q3458,20#,45#, etc. |

| Brass | C35600,C36000,C37000,C37700,C37100,C28000,C26000,C24000,C22000,etc. |

| Copper | C11000,C12000,C12200,C10100,etc. |

| Iron | 20#,45#,Q235,Q345,Q3458,1214,12L14,1215,etc. |

| Plastic | POM,Peek,PMMA,ABS,Delrin,Nylon,PVC,PP,PC,etc. |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating. etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Power Coated, Nickel Plated, etc. |

| Plastic | Plating gold(ABS),Painting,Brushing(Acylic),laser engraving |