Your Reliable Pogo Pin Manufacturer

A Pogo pin or spring loaded pin is a connector widely used in modern electronics. Dongguan Promax is a professional pogo pin manufacturer. Experts in the field of high precision, unique, intelligent pogo pins, confident in the design, quality, manufacturing technology, service, and delivery!

Ensure > 95% sample FPY and > 99% volume production FPY. (FPY: First Pass Yield, is the quality indicator)As the world’s leading pogo pin manufacturer, Dongguan Promax offers excellent ODM services and competitive prices.

Pogo Pin

Safe & On-Time Delivery

Leave your requirements and let Dongguan Promax handle the rest.

24/7 Online Support

Dongguan Promax is always here to support your business.

Competitive Price

Get better shipping rates to reduce your costs.

Pogo pin design

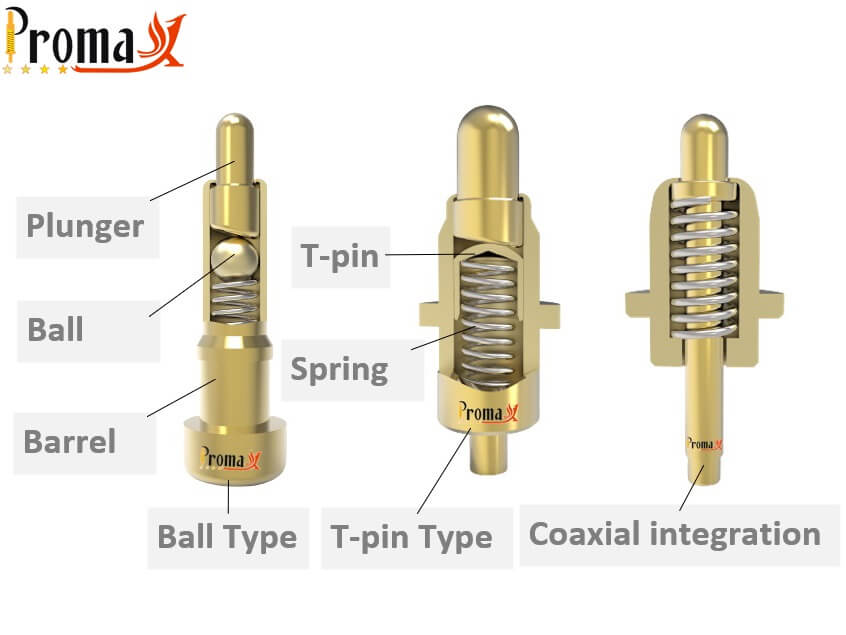

A Pogo pin consists of three main parts: a spring loaded plunger pin, a spring loaded locking pin, and a spring. Based on customer requirements, we can implement various designs such as Bias Tail, Back Drilling, Ball, T-pin, or Coaxial.

These specialized designs can reduce the electrical resistance of the Pogo pin, thereby accommodating high current demands from customers.

How about our product quality?

Gage R&R (ANOVA) for Press Fit

Pogo Pin Process

Our production process for Pogo pins includes six steps: turning, grinding, plating, assembly, inspection, and packaging.

First, brass is machined into a specific shape using a lathe, followed by tolerance adjustments with a grinding machine.

Next, the parts are sent to the plating facility for electroplating.

After plating, the components are sent to the assembly workshop. They then undergo inspection to ensure proper functionality.

Finally, the Pogo pins are packaged.

Our Customer Said

Dongguan Promax has assisted us with numerous on-site issues.

Their experienced engineers quickly resolved the high-temperature problem caused by excessive current in pogo pins.

I highly recommend them as a connector solution provider.

Paul Jelloy

Customer from UK

Package of pogo pin

We typically use reel packaging. First, the Pogo pins are placed on a custom-sized carrier tape, then rolled onto a reel using a tray. This method effectively prevents collision damage and reduces overall packaging space.

We have multiple automatic packaging machines, which are five times more efficient than manual methods, ensuring high production efficiency.

FAQ

Spring loaded pin is an electrical connector structure used in modern electronic applications. They are more durable than other electrical connectors.

The name spring loaded pogo pin comes from the pin’s resemblance to a pogo stick – the integrated helical spring in the pin applies a constant normal force against the back of the mating receptacle or contact plate, counteracting any unwanted movement which might otherwise cause an intermittent connection.

- Free Height: is no load height, full extension height of spring

- Working Height: is the ideal load height for spring

- Maximum Load Height: is the maximum load height of the spring, usually, contacting the end of the barrel

- At Dongguan Proma, the Spring loaded pin life cycle is in the range of 10,000 to 100,000 times

- Mechanical life cycle: maximum working times to ensure spring force in spec

- Electrical life cycle: maximum working times to ensure contact resistance in spec

Dongguan Promax focuses on consumer electronics, new energy, chip testing, communications, smart home, medical, entertainment, security, retail, personal and industrial connector fields, and ODM services;

Always customer-centered, with the best technology, the highest quality, the best cost, the best service, the shortest delivery time, for Huawei, Millet, Amphenol, and other international and domestic well-known customers, to provide performance, life, reliability, security, economic and excellent products, and services!

With a perfect after-sales guarantee system, the service is more efficient, but also constantly expanding domestic and foreign high-quality customer groups!