Last Updated on September 27, 2023 by Tony

Precision manufacturing is crucial in the modern electronics landscape. One essential component requiring precision is the Pogo pin or a spring-loaded pin.

These small connectors are vital for establishing electrical connections in electronic devices. CNC turning machines are essential for achieving the necessary precision.

This guide explores Pogo pins and how CNC turning machines have transformed their manufacturing.

Whether you’re an engineer looking to improve production or an enthusiast wanting to understand precision engineering, this article is your ultimate resource.

We’ll cover Pogo pin basics, CNC turning machine operation, and a detailed production process, giving you the knowledge to produce these connectors effectively.

What Are Pogo Pins?

Pogo pins quietly ensure reliable electrical conductivity in electronic devices. Their key components include a housing, plunger, spring, and contact.

When pressure is applied, the plunger retracts against the spring, ensuring precise electrical contact with the target surface, even in vibrating or moving applications.

With various sizes and configurations, they accommodate different design needs. Despite their small size, their precision and reliability are indispensable in electronics.

Getting Started with Pogo Pin Production

Choosing the Perfect Material

As it affects their performance and durability, selecting the ideal material for Pogo pins is vital.

Brass and stainless steel are common options with distinct properties suited to specific applications.

Your selection should align with your project’s requirements, encompassing electrical performance, environmental factors, and ease of manufacturing.

Brass: A Conductor of Excellence

Brass excels in electrical conductivity, ensuring reliable connections in electronic devices. Its corrosion resistance enhances Pogo pin longevity, while its ease of machining simplifies production.

Stainless Steel: A Fortress Against Corrosion

Stainless steel stands out for its corrosion resistance and strength, making it ideal for applications exposed to moisture or chemicals. Stainless steel Pogo pins are reliable in harsh conditions, making them indispensable in industries where durability is paramount.

Material Preparation

The first step before machining is to prepare precise blanks from the chosen material. The quality and accuracy of these blanks directly affect the final product.

Once the material is selected, transform larger pieces into precisely measured blanks using equipment like saws for clean, accurate cuts, ensuring alignment with the required Pogo pin dimensions.

Setting Up the CNC Turning Machine

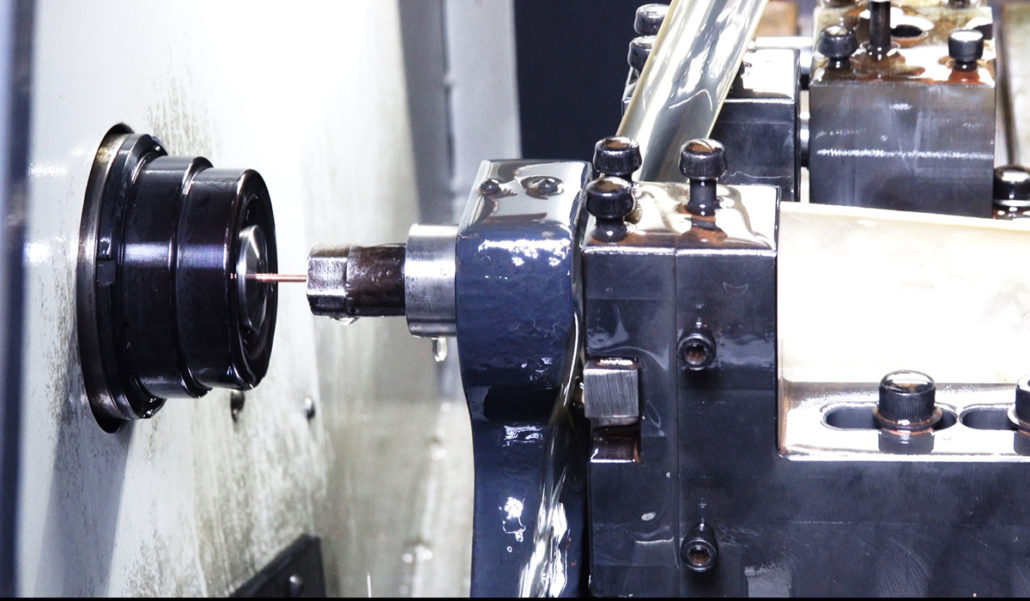

The CNC Turning Machine

The CNC turning machine is crucial in Pogo pin production, and understanding its components and setup is essential for precision manufacturing success.

Machine Components

Familiarize yourself with the primary components of a CNC turning machine:

- Chuck or Collet: The chuck or collet is the mechanism that holds the workpiece securely in place during machining.

- Tool Holders: Tool holders are instrumental in securing cutting tools and ensuring stability and precision during machining.

- Spindle: The spindle rotates the workpiece, allowing for precise material removal.

Understanding these components is essential for setting up and operating the CNC turning machine effectively.

Workpiece Securing

Securely placing the prepared workpiece in the chuck or collet is vital for stability during machining. This foundation ensures accuracy and precision in the machining process.

While techniques may vary based on the CNC turning machine, the goal is always the same: preventing unwanted movement during machining.

Tool Selection and Setup

Choosing the Right Tools

Explore the nuances of cutting tools like carbide inserts, drills, and end mills. Each tool excels in specific applications, so understanding their strengths and limitations is essential.

Consider factors like the material being machined, required surface finish, and feature complexity to ensure optimal tool selection.

Tool Installation

Mastering tool installation is paramount. Properly securing each tool in the holder prevents movement or vibration during machining. Even slight misalignment or instability can lead to errors in the final product. Correct installation guarantees precise tool performance.

Tool Alignment

Precision machining requires meticulous tool alignment within the machine. Proper alignment minimizes errors during machining, ensuring accuracy in following programmed toolpaths. Align tools carefully and promptly correct any deviations from the desired position.

Tool Offsets and Compensation

Setting tool offsets and compensation is of utmost importance. These adjustments enable the CNC machine to accurately follow programmed toolpaths, accounting for variations in tool dimensions and workpiece irregularities.

Proficiency in configuring and adjusting these parameters is integral to achieving the precision needed in Pogo pin manufacturing.

Crafting the CNC Program

CNC programming is the language that directs the CNC machine’s actions. It serves as the digital blueprint for the manufacturing process. Below is a brief breakdown of Crafting the CNC Program.

Understanding G-codes and M-codes

G-codes and M-codes are alphanumeric commands that define machine actions, like controlling tool movement, coolant flow, or spindle speed. Proficiency in deciphering and using these codes effectively is essential for creating a precise CNC program.

Creating a Precise Program

Translating Pogo pin design specifications, dimensions, and tolerances into a precise CNC program is pivotal. The program should encompass all necessary machining operations, toolpaths, and parameters.

We offer practical tips and examples to help you create a foolproof program, ensuring accuracy and repeatability in Pogo pin production.

The Art of CNC Machining

CNC machining is where the turning machine truly excels, shaping raw materials into precise components. Let’s delve into the specific operations for crafting Pogo pins.

Facing

Facing marks the machining process’s start, creating a flat, smooth workpiece surface. This step establishes a reference point for subsequent operations, ensuring precise alignment of all features and dimensions.

Turning

Turning is a core machining operation, removing material from the workpiece’s outer diameter to achieve the desired shape and dimensions. Precision is key to meeting Pogo pin specifications.

Drilling

Drilling creates holes in the workpiece for pin or component insertion. Accurate hole placement and dimensions are critical for seamless Pogo pin integration into electronic devices.

Threading

Threading precisely creates screw threads on the workpiece, especially crucial when Pogo pins require screw-like features for secure connections. Achieving the correct thread pitch and depth is vital for pin functionality.

Lubricants and Coolants: Your Allies

Using lubricants and coolants can significantly improve the quality and efficiency of Pogo pin production during CNC machining.

Role of Lubricants

Lubricants reduce friction between the cutting tool and the workpiece, extending the life of the cutting tools. Effective lubrication ensures a smooth and precise machining process.

Importance of Coolants

Coolants are equally vital during machining, dissipating heat generated during cutting and machining operations. Efficient heat dissipation is crucial to preserve tool integrity and workpiece quality. Inadequate cooling can lead to tool wear, material deformation, and dimensional inaccuracies.

Selecting and applying lubricants and coolants are precise processes that require meticulous execution to optimize machining performance.

Quality Control and Precision

Quality control measures should be an integral part of your production process. Meticulous attention to detail is necessary at every manufacturing step, from material preparation to final inspection.

Measuring Tools

Measuring tools, like calipers and micrometers, are trusted allies in pursuit of precision. They enable precise measurements of workpieces, verifying dimensions to the fraction of a millimeter, ensuring Pogo pins meet exacting standards.

Checking Tolerances

Tolerances are permissible variations in pin dimensions and specifications. Understanding and adhering to these tolerances is crucial. Verification that pins fall within these limits guarantees flawless functionality once integrated into electronic devices.

Adding the Finishing Touch

While functionality is the primary focus in Pogo pin production, aesthetics can also matter in specific applications. Achieving a pristine surface finish enhances the visual appeal and can contribute to overall performance.

Grinding

Grinding is a precision process that smooths and refines pin surfaces, removing imperfections or irregularities for a flawless appearance. A smooth surface improves electrical conductivity, ensuring a polished look and optimal performance.

Polishing

Polishing further refines the pins, enhancing shine and conductivity. This step is crucial for applications where electrical performance is paramount, such as high-frequency connectors. A polished surface not only improves aesthetics but also enhances electrical contact.

Plating Options

Consider various plating options based on your project’s specific needs to enhance Pogo pin performance and durability. Gold or nickel plating offers distinct advantages:

- Gold Plating: Known for excellent electrical conductivity and corrosion resistance, gold plating ensures reliable electrical connections even in demanding environments.

- Nickel Plating: Nickel plating provides a robust protective layer, enhancing pin durability, especially against corrosion and wear.

The choice of plating depends on the intended application and required performance characteristics for the Pogo pins.

Inspection and Packaging Excellence

Ensuring every pin leaving your production line is flawless demonstrates your commitment to quality.

Defect Detection

Despite precise machining, occasional defects like burrs or deviations can occur. Inspection tools and techniques identify these issues early, allowing corrections before pins proceed in production.

Quality Assurance

Implementing stringent quality assurance is vital. It guarantees each Pogo pin meets high reliability and performance standards. Quality checks must be integral in production, with subpar pins set aside for rework or disposal. This commitment upholds your reputation and ensures device reliability.

The Final Presentation

Packaging for Pogo pins is the last step but no less critical. Proper packaging ensures delicate pins reach their destination undamaged. Consider:

Packaging Materials

Select suitable packaging materials to safeguard pins during shipping and handling. Anti-static packaging is crucial for sensitive electronic components, preventing electrostatic discharge (ESD) that could harm them.

Record-Keeping

Maintaining detailed machining records isn’t just documentation; it’s about consistency and traceability.

Records should encompass tool settings, program details, inspection results, deviations, and corrective actions. This documentation serves as a valuable resource for reference and continuous improvement.

Prioritizing Safety

A culture of safety isn’t just a responsibility; it’s a commitment to the well-being of all involved in the production process.

Machine Safety Guidelines

Start by thoroughly familiarizing yourself with machine safety guidelines to prevent accidents and injuries. Strict adherence is essential and may include protocols for machine startup and shutdown, tool changes, and emergency procedures.

Protective Gear

Personal protective equipment (PPE) serves as your primary defense against hazards. Depending on your role and facility regulations, you might require safety glasses, gloves, ear protection, and other gear.

Wearing the appropriate PPE is essential to ensure your safety and the safety of those nearby.

Advanced Techniques and Tips for Precision Machining

As you advance in Pogo pin production, continuous improvement is key. Advanced toolpath optimization techniques can boost efficiency and precision, taking your machining process to the next level.

Workholding Solutions

In precision machining, stability and accuracy are paramount. Employing different work holding methods and custom fixtures designed for Pogo pin production can enhance your process.

These solutions improve stability, reduce setup times, and ensure consistent results.

Troubleshooting Common Machining Challenges

Managing Chip Formation

Chip formation is inherent to machining but can present issues like chip jamming leading to tool breakage or surface defects on Pogo pins.

Understanding chip dynamics and implementing strategies to address these challenges is vital for seamless production.

Tool Wear and Maintenance

Tools are central to machining, and their wear and maintenance significantly impact quality consistency. Recognizing signs of tool wear, knowing when to perform maintenance, and identifying the right time for tool replacement are essential for long-term success in Pogo pin production.

Sustainability: Environmental Considerations

Today, sustainability is a responsibility, not just a buzzword. Applying sustainable manufacturing to Pogo pin production can reduce waste, energy use, and environmental impact.

Strategies like recycling cutting fluids, optimizing machining for efficiency, and reducing material waste are essential. Committing to sustainability benefits the environment and aligns with responsible manufacturing expectations.

Conclusion

In essence, mastering the production of Pogo pins with CNC turning machines is a journey of dedication, precision, and continuous improvement.

These connectors are essential in electronics, and your expertise can significantly impact device reliability and performance.

Every Pogo pin you create represents your commitment to precision and manufacturing excellence.

As you embark on this journey, remember that your expertise contributes to the smooth operation of the electronic devices powering our modern world.

Precision in Pogo pin production isn’t just a skill; it’s a cornerstone of progress in the electronics industry.