Last Updated on March 21, 2024 by Tony

Before our electronic components and devices are pushed to the market, they need to undergo EMI and EMC testing. But do you know the difference between the EMC and EMI? While they are related, understanding the distinction between EMI and EMC is crucial for the success of the product.

What is the difference between EMC and EMI?

The differences between EMC and EMI are easily distinguishable. The following four points can help you better differentiate between them:

1. Focus:

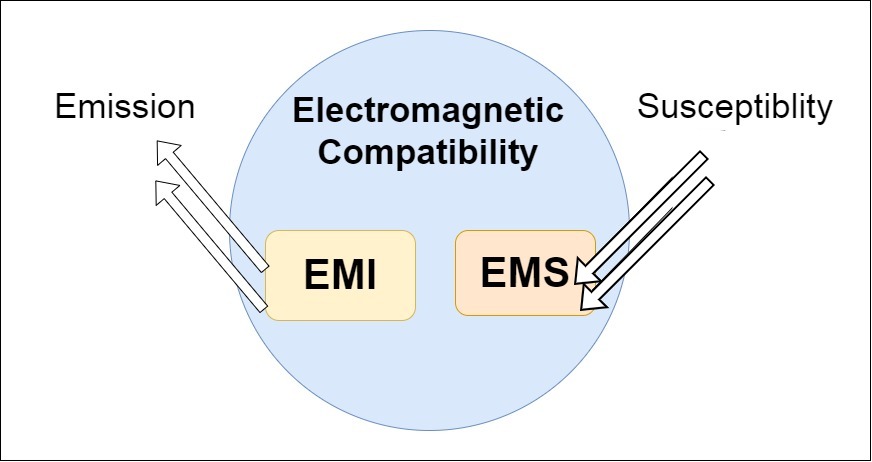

- EMC: The ability of devices to coexist and operate normally in an electromagnetic environment, including resistance to external interference and the prevention of interference to surrounding devices.

- EMI: The ability of electromagnetic radiation to interfere with other devices or systems.

2. Application areas:

- EMC: Involves device design, testing, and management to ensure devices can operate properly in electromagnetic environments without interference or causing interference.

- EMI: Mainly involves electromagnetic compatibility testing, interference source identification, interference suppression, etc.

3. Testing methods:

- EMC: Includes pre-compliance testing and compliance testing, where pre-compliance testing is used to identify potential EMC issues and compliance testing ensures products meet relevant regulatory standards.

- EMI: Includes measuring radiated and conducted interference, as well as assessing device tolerance, which typically involves using equipment such as spectrum analyzers, EMC receivers, etc.

What is EMC and EMI?

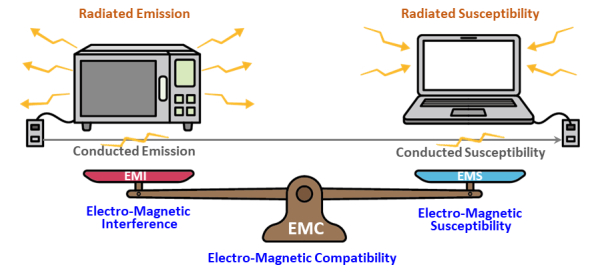

EMI stands for electromagnetic interference, which is the electromagnetic energy that affects the functionality of electronic components and devices. EMC, on the other hand, stands for electromagnetic compatibility, which measures the ability of a device to operate as intended in its shared operational environment without affecting the ability of other devices in the same environment to operate as intended.

EMC is a critical engineering consideration in any system. Devices that fail EMC testing may lead to various negative outcomes, including safety risks, product failures, and data loss. Therefore, various EMC and EMI testing equipment have been developed to enable engineers to gain a clearer understanding of how devices are affected by electromagnetic interference in real-world conditions.

The Application of EMC and EMI

EMC and EMI have wide-ranging applications across almost every industry that utilizes electronic devices. Below are their main application areas:

Application of EMC:

- Electronics Manufacturing: Ensuring the electromagnetic compatibility of electronic products in different environments to avoid interference with other devices or susceptibility to external interference.

- Automotive Industry: Various electronic systems in automobiles (such as engine control, in-car entertainment, safety systems, etc.) need to undergo EMC testing to ensure their reliability and safety in vehicle environments.

- Aerospace Industry: Aerospace components and systems must be EMC-certified to ensure stability and reliability in extreme environments.

- Telecommunications and Radio Equipment: Devices such as mobile phones, communication base stations, wireless routers, etc., need to undergo EMC testing to ensure they do not interfere with each other or are susceptible to external interference.

- Medical Equipment: Medical devices must meet strict EMC standards to ensure their safety and reliability in environments like hospitals.

- Industrial Automation: Various industrial automation equipment and control systems need to undergo EMC testing to ensure stability and reliability in factory environments.

Application of EMI:

- Electromagnetic Compatibility Testing: EMI testing is used to assess the interference level of devices in electromagnetic environments to ensure they do not interfere with other devices in coexistence.

- Interference Source Identification: Identifying potential electromagnetic interference sources and taking measures to reduce their impact on surrounding devices.

- Product Certification and Compliance Testing: EMI testing is an integral part of product certification to ensure compliance with relevant regulations and standards.

- Interference Suppression: Taking measures against identified interference sources, such as filters, shielding, etc., to reduce or eliminate their interference with surrounding devices.

- Electromagnetic Environment Management: Monitoring and managing the electromagnetic environment to ensure device compatibility and stability in different environments.

In summary, EMC and EMI play vital roles across various industries and applications, ensuring the reliability, safety, and performance of electronic devices.

Test methods for EMC and EMI

When it comes to testing EMC and EMI, the following testing methods and techniques can help you measure more effectively.

EMI Testing Methods:

1. Radiated Interference Testing:

- Radiated Field Measurement: Utilizes antennas and power measurement equipment to measure the electromagnetic field intensity radiated by the device, assessing its radiation levels across different frequency ranges.

- Radiated Frequency Range Scan: Uses spectrum analyzers to scan the frequency range of device radiation, identifying potential interference sources and frequencies.

- Radiated Conducted Testing: Evaluates the device’s radiated interference characteristics by measuring electromagnetic interference conducted in wires and cables.

2. Conducted Interference Testing:

- Conducted Electrical Testing: Measures the electrical characteristics of the device on power and signal lines to assess its sensitivity to external interference.

- Conducted Frequency Range Scan: Evaluates the device’s conducted interference characteristics by connecting it to a signal source and scanning frequency ranges.

EMC Testing Methods:

1. Electrical Testing:

- Power Line Conducted Testing: Evaluates the device’s conducted electromagnetic interference characteristics on power lines.

- Signal Line Conducted Testing: Assesses the device’s conducted electromagnetic interference characteristics on signal lines.

- Electrical Parameter Measurement: Measures the device’s electrical parameters such as current, voltage, and power to assess its electrical characteristics.

2. Environmental Testing:

- Temperature and Humidity Testing: Evaluate the device’s performance under different temperature and humidity conditions.

- Mechanical Vibration and Shock Testing: Assesses the device’s tolerance under mechanical vibration and shock conditions.

3. Interference Resilience Testing:

- Radiated Electromagnetic Field Testing: Places the device in an external electromagnetic field and evaluates its resilience to radiated electromagnetic fields.

- Conducted Interference Source Testing: Connects the device to conducted interference sources and evaluates its resilience to conducted interference.

These testing methods help assess the device’s electromagnetic compatibility and interference characteristics, providing guidance for device design and manufacturing to ensure normal operation under various electromagnetic environments.

EMI and EMC Compliance

EMI and EMC compliance standards vary across the world, with different regulatory bodies having their own specific standards. The compliance standards in the European Union, for instance, differ from those in other countries. Additionally, the military sector adheres to stricter standards compared to the commercial industry. The final intended use of specific industries and devices may also diverge from commercial compliance standards.

Here are some of the most common compliance standards that must be met, as a reference:

- FCC Part 15 specifies the EMC testing standards for consumer devices in the United States.

- Military EMC testing standards can be found in MIL-STD 461 and MIL-STD 464.

- In the European Union, specifications managed by ISO, IEC, CISPR, and similar organizations govern EMI and EMC compliance.

Compliance testing must cover susceptibility and emissions:

- Susceptibility testing assesses a device’s sensitivity to EMI and whether it operates as designed in the presence of specified intensities of EMI (continuous and intermittent).

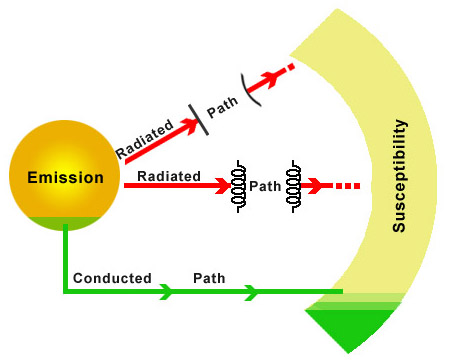

- Emission testing ensures that any EMI emitted by the device remains within specified limits, thereby not causing auxiliary devices to malfunction. Since EMI can occur through conduction and radiation, comprehensive emission testing scenarios must encompass both conducted EMI and radiated EMI.

Conclusion

A clear understanding of the difference between EMI and EMC is highly beneficial for engineers developing new products. Not only does it protect electronic devices from electromagnetic interference, but it also helps avoid external disturbances.

Familiarity with their distinct testing methods can also assist engineers in enhancing electronic devices to meet compliance requirements more effectively. Additionally, adhering to industry standards across different countries is essential. In summary, reading the above text can better aid in understanding the differences between EMC and EMI.