Last Updated on June 20, 2023 by Tony

- Do you want to increase the reliability and efficiency of your electronic contacts? Or do you always struggle to make small adjustments to your equipment because of complicated connections?

- The only solution to these and tens of other problems are spring-loaded pins.

- Spring-loaded pins make your electronic contacts much more reliable, efficient, stable, and productive. Also, they can be really helpful in making the connectivity option much easier for people. These pins offer a much more affordable price as compared to traditional pins.

- So, if you have casually searched for the pogo pin’s installation process to finalize your purchasing decision, you should consider proceeding with the purchase without further do.

- To have a detailed knowledge of the product, check out our

- However, if you have already purchased one and looking to install it, make sure to read the entire installation process.

How To Install Spring Loaded Pins (Step-By-Step Process)

The installation process of spring-loaded pins can be divided into two methods.

- Manual Process

- Automatic Process (Installed by machine)

Manual Process

The manual process is one of the easiest ones of them all. You should consider using it if you are making the installations of spring-loaded pins at a smaller scale. To begin with the manual installation process, you will need to use a hand press and pin-driving chuck. After having both the equipment, take the following steps to get the job done.

- Insert the pins from the open side into the driver.

- Place the exposed end of the pin into the hole and push it by using the press handle

- Make sure the contact is made properly without any loss issues by checking the fix.

- The manual process is perfect for manufacturers running small-scale production. It is a better affordable option with extremely low up-front costs.

- That said, it offers some of the greatest advantages. Some of them include:

- Controlled insertion depth, proper alignment, and quicker cycle times with the help of a pin-driving chuck.

- Chuck holds the pins securely, which reduces the risk of any losses.

- Fast-paced installation for smaller production units.

Automatic Process (Installed by Machine)

- The next process for the installation of pogo pins is the automatic one. The process is generally carried out by a machine that helps automate the process and gives the manufacturers a good production rate.

- The machine also helps in reducing the installation time for the pogo pins, which can be helpful for large production setups.

- Before we look into the steps, let us understand the working mechanism of the spring-loaded pins installation machines.

Automatic Pin Installation Machines Working Mechanism

- It contains a fastener that is oriented directly into the vibratory feeder.

- The fastener is fed to the shuttle mechanism by which it places itself under the insertion quill.

- Then, the shuttle is placed on the retracting mechanism that positions the pin exit bushing close to the assembly.

- The assembly backed by the entire mechanism process handles the loading and unloading of the pins.

- The working mechanism of the machine might seem quite complicated. However, you don’t need to get into the process complications if you just want to install the pins.

- Take a look at the steps you should take to get the installation done automatically.

- Get a high-quality automatic pin inserter machine.

- Once you start the machine, the operator will be able to load the assembly into the machine’s fixer.

- Activate the pin insertion option on the machine.

- Insert the pin onto the assembly and then remove the assembly from the fixture.

- Supply the pins into the feeder balls as per the contacts.

- The machine will install the pins according to the number of pins you have inserted in the feeder

- The installation of the pin runs entirely on automation. You don’t need to take control of the process multiple times. Instead, you just need to insert the pins into the assembly fixture in the right way and the machine will continue the process.

- There are certain other advantages of using automatic pin installation machines. Some of them include:

- Certain added features such as infrared safety lights, rotary index tables, adjustable working space, etc.

- The machine automatically adjusts the designs, fixtures, and shapes of the components.

- Reduced scrapped assemblies, improved cycle times, faster production rates, and high return on investment.

Now that you know how to install pogo pins, let’s take a look at some of the points you should keep in mind before installation.

Tips To Effectively Install Pogo Pins

Installing pogo pins can be an excellent way to improve the connectivity of your electronic products. However, it is important to consider a few things before actually installing the pins.

1. Fixturing

- pogo pin sizing and positioning are important in electronics items. pogo pins have a specific job and they need to be placed correctly in order to work properly.

- If they are too tight, the device may malfunction and if they are too loose, it can get damaged. Pogo pins also have a significant impact on how the device operates.

- Considering this, you need to pay special attention to the utilization of the fixturing in a proper way. It will help in adjusting the size and position of the pin to avoid any issues.

2. Alignment Of The Assembly

- Pogo pins are often put in place with the assembly by the machine to apply proper fixing. It requires a set of design tools that help align the pogo pinholes with the positions on the tang of the assembly. The alignment of these holes and tangs can be difficult to achieve manually.

- So, if you are carrying out the installation process manually, make sure to adjust the pin properly before applying any load.

3. Applied Load On The Pin

- If a pogo pin is being installed in an electronic device, applying an upward force on the pin will make it easier to push it into its desired location. This is accomplished by attaching something like a spring-loaded tool or even just a piece of wire to the end of the pin and pulling it up when it’s inserted.

- However, if you are following a manual process or installing it with a hammer, don’t hit it hard. If you do, the pin might break without even entering the hole.

Benefits Of Using Spring Loaded Pins

Using spring-loaded pins offers a wide range of benefits. Take a look at a few of them.

1. Easy To Use

- Pogo pins are an important part of making electronic circuits. They make contact with the wires and ensure that there is contact in certain places so that when you assemble your circuit it works properly and reliably. They are very easy to use and are great for beginners who need a little bit of guidance.

2. More Durable

- Electronics must be able to handle a lot of wear and tear. To give them more durability, manufacturers use pogo pins in electronic pieces.

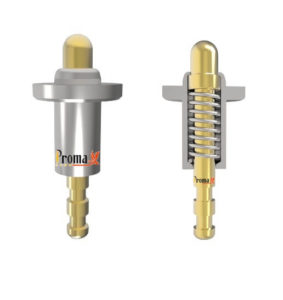

- The contact point at the end of the Pogo Pin is usually the ball head. The internal spring generates a reaction force due to the compression of the plunger. The reaction force of the spring is transmitted to the plunger so that the plunger and PCB board or mating part are in close contact together, and the signal or current is transmitted stably. These features make the pogo pins highly durable and strong to tolerate different current conditions.

3. High Vibration Tolerance

- Spring-loaded pins are a common design for electronic components. They are used because they are more flexible than magnets, which means they can be used on both flex and non-flexible PCBs.

- When the spring is pushed in any direction, it will return to its original position; this allows the device to have high vibration tolerance and low resistance force.

4. Consistent Contact

- Pogo pins are generally used to make contact with electronic devices. The metal prongs of the pin are pushed into the electronic device to be connected. Pogo pins help improve the quality and longevity of these connections by making sure that there is constant contact between the two items. It helps prevent sparks and other dangerous situations from occurring when there is a break in contact between items.

5. Perfect For Cable Connections

- Pogo pins are a great way to make sure that the wire connection on your cables stays nice and secure. They hold the cable in place without needing any extra holding devices, like pigtails. This makes it easy for future cable changes or repairs.

Conclusion

- Spring-loaded pins offer a wide range of features, benefits, and affordability. Also, the installation process is relatively easier than conventional pins.

- All you need to have is a good understanding of your production needs. Once you are sure about it, choose the installation process that fits your needs and begin with it.

- If you are still stuck with any of the steps, feel free to mention them in the comments. We would love to clear it out for you in detail.