Spring Probe

Are you finding a test probe or spring probe of the right size? are you worried about a high-quality product, with the shortest delivery date, the lowest cost, and the best services? Dongguan Promax is the best, as a professional pogo pins ODM Manufacturer & Vendor since 2014, we are confident in providing you with the best proposal and technical solutions, fixing your issues, and meeting your targets!

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

all types of customization

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

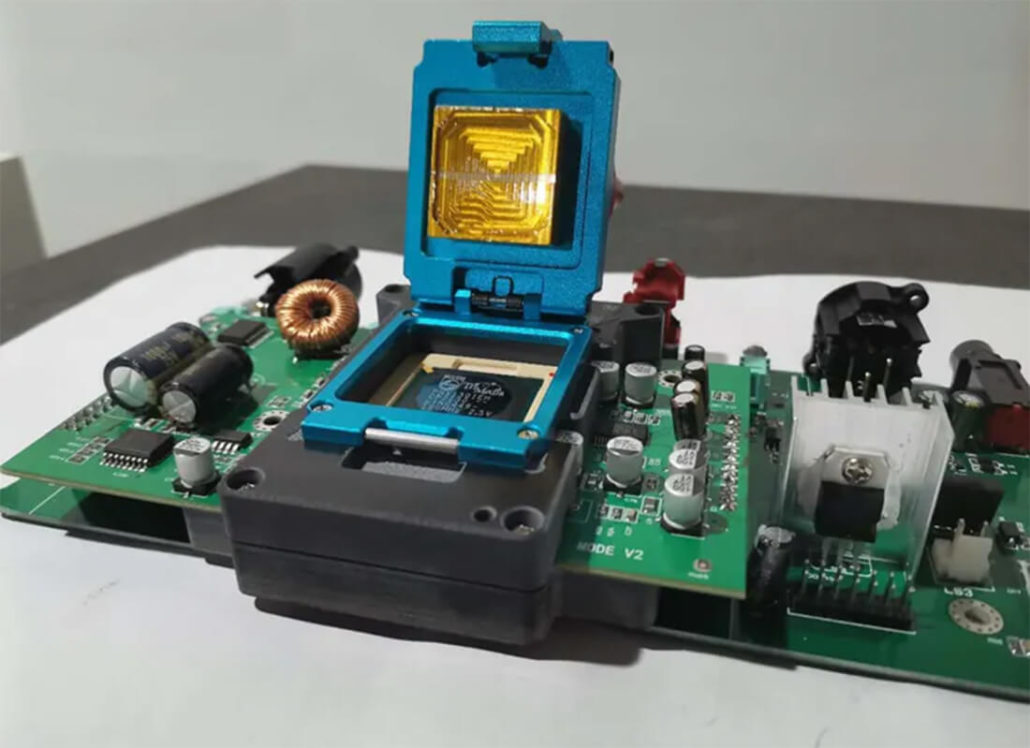

Use Case of Through Hole Pogo Pin Connector

The case was describing a spring probe used in a BGA test socket, which was to test a BGA chipset in a mixer console from a Europe professional stage audio equipment manufacturer MUSIC Group. Read More ReadLess

Based on the customer’s requests, all spring probes in the BGA test socket were needed to ensure the best signal communication and the best power conduction. Read More ReadLess

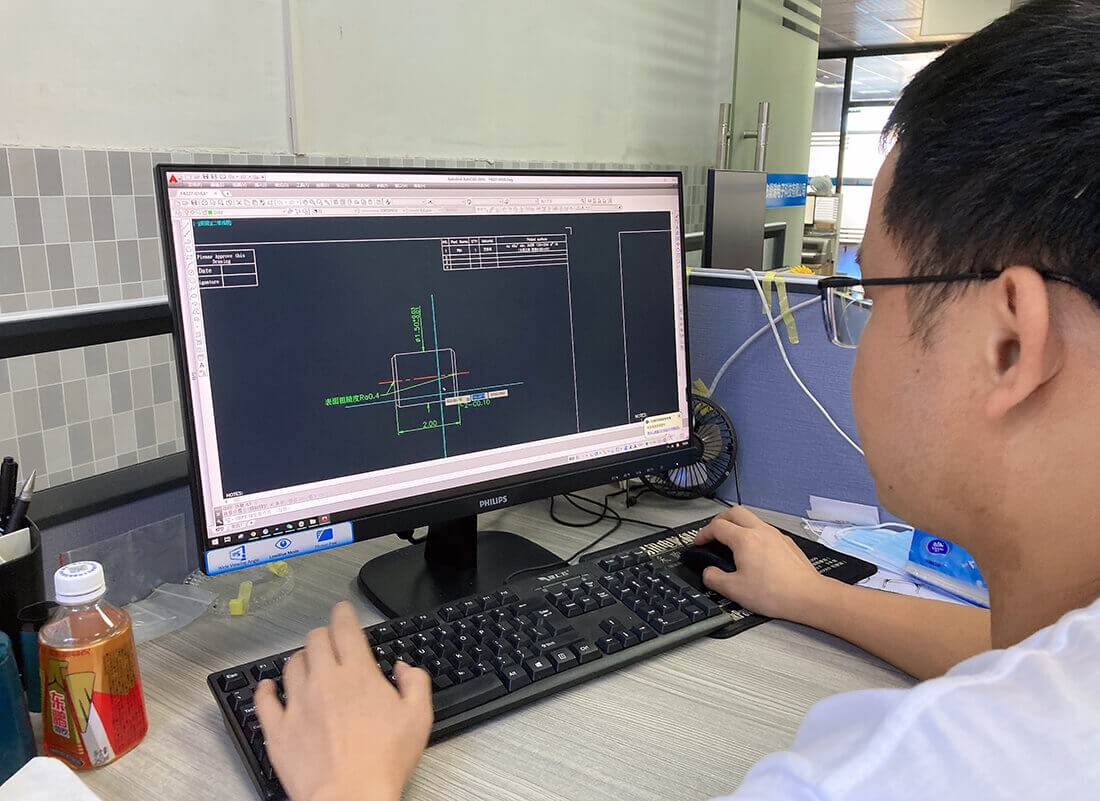

Studied Customer Requirements

Based on the precise BGA size and pitch, we designed the spring probe and BGA test socket at the same time. for the spring probe. For the BGA test socket, it was just a container to fix 498 spring probes, its pitch was 0.8mm, and its material was PEEK and Telfon. Read More ReadLess

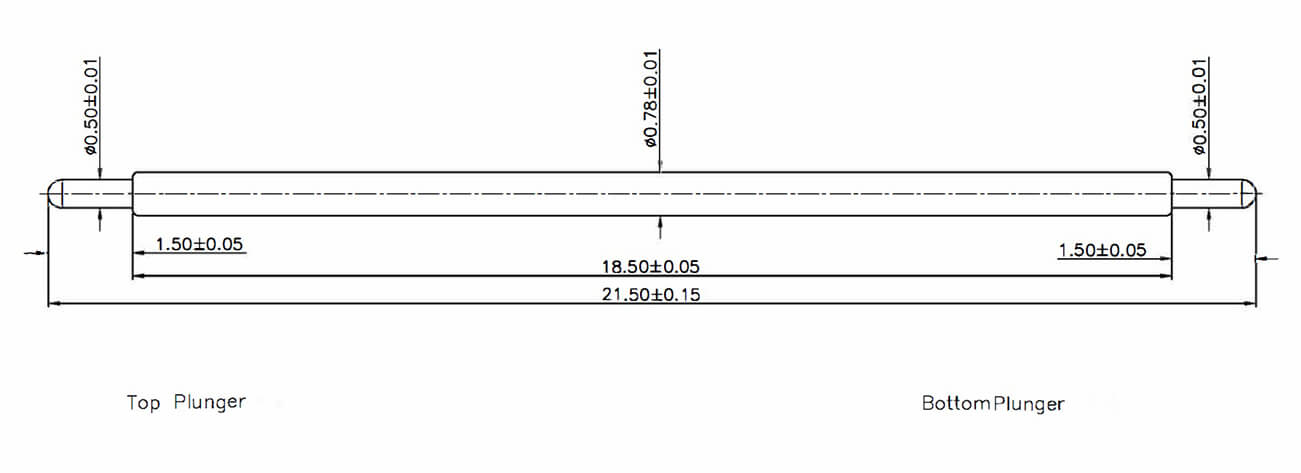

Design of Spring Probe

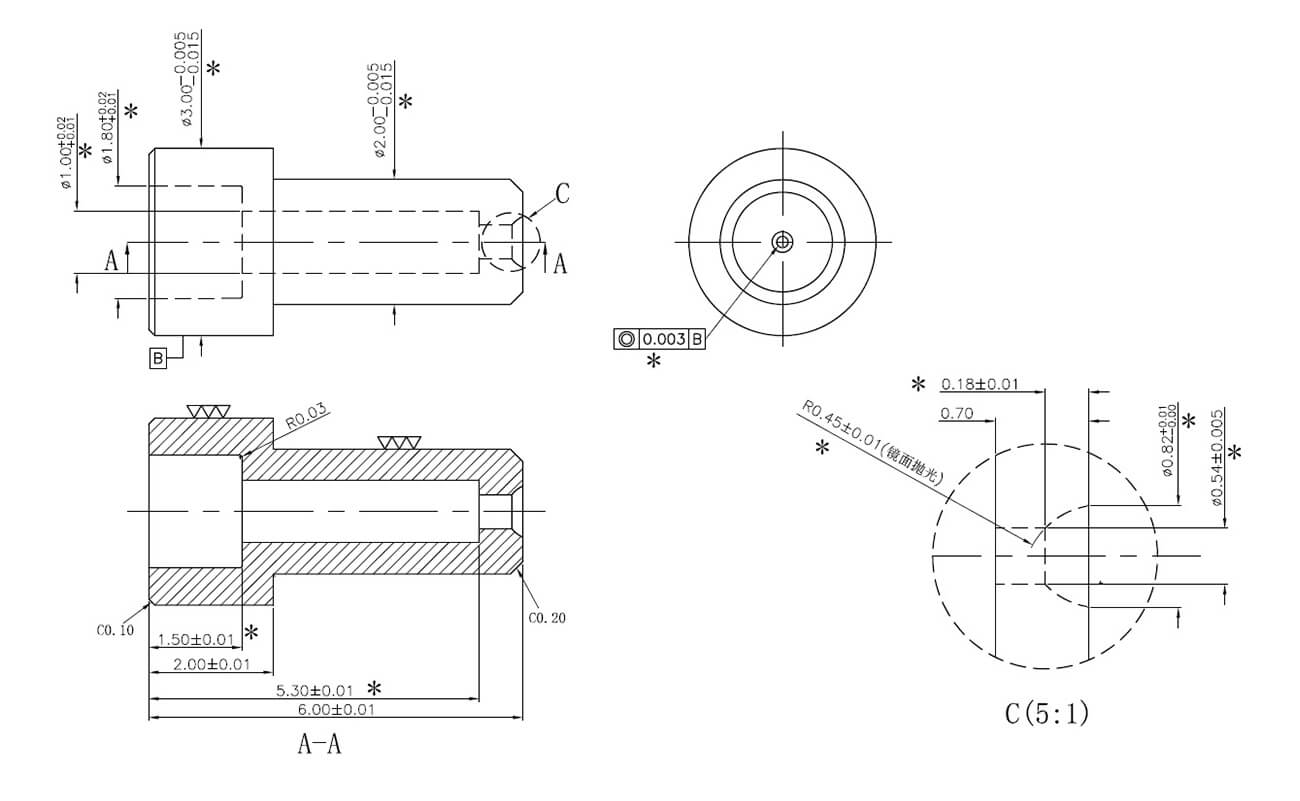

The spring probe was designed as two same plungers and one barrel. in industry, we called two plungers: one was the top plunger, and the other was the bottom plunger, their outer diameter was Φ0.50mm, and the outer diameter of the spring probe was Φ0.78mm. total length was 21.5mm. Read More ReadLess

What is Spring Probe’s Structure?

The spring probe is the contact medium for electrical testing and is a high-end precision electronic hardware component. It mainly consists of three parts: spring, plunger, and barrel. Read More ReadLess

What is The Working Principle of The Spring Probe?

Testing whether the dut is working properly can give the manufacturer feedback on their process problems. Meanwhile, It can screen out the bad products to reduce the waste of subsequent finished products. Read More ReadLess

What is The Material and Surface Treatment of the Spring Probe?

| Main Materials | |

|---|---|

| Aluminum | AI6061, AI6063, AI6082, AI7075, AI2024, AI5052, A380, etc. |

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q3458, 20#, 45#, etc. |

| Brass | C35600, C36000, C37000, C37700, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper | C11000, C12000, C12200, C10100, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc. |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating. etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Power Coated, Nickel Plated, etc. |

| Plastic | Plating gold(ABS), Painting, Brushing(Acylic), laser engraving |

What is Spring Probe Tip Type?

Spring probe is widely used in electronic products such as mobile phones and plays a test role. The spring probe is equivalent to a medium. During the test, the head of the probe can be used to contact the object to be tested,

Read More

ReadLess

How to Choose The Right One?

It is important to choose a good one that will help you to check whether the semi-finished product is qualified or not. A qualified product is crucial for any company. So how do you choose a good one?

Read More

ReadLess

Why Dongguan Promax?

When it comes to test probes, few companies can match the level of skill and expertise demonstrated by Dongguan Promax. With over 15 years of experience in the field.

Read More

ReadLess