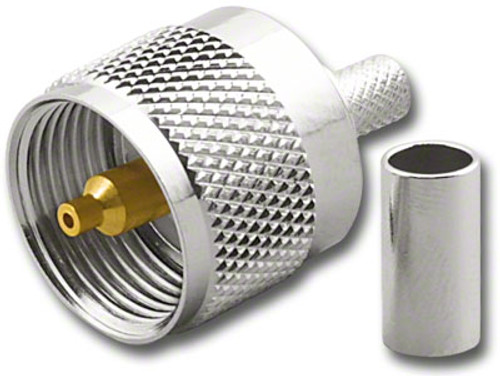

The PI-259 connector, also called an RF connector, is a pivotal player in electronics, linking different parts for smooth data flow. It uses a special threaded mechanism and comes in various sizes tailored to specific needs.

This connector quietly handles data exchange, ensuring strong Wi-Fi, clear TV, and uninterrupted phone calls.

Signal quality is vital for a smooth digital experience in our connected world. Poor signals lead to issues like pixelation and sound hiccups during streaming.

Optimizing the PI-259 connector is crucial for clear, uninterrupted, and distortion-free signal transmission. It results in better audio, sharper video, faster data transfer, and seamless user experience, transforming Wi-Fi, TV, and phone calls.

Optimizing PI-259 connectors gives you these benefits:

- Enhanced Signal Quality: No more fuzzy video calls or sluggish data transfers. Optimization ensures top-notch signal quality.

- Reliability: Reduced signal loss means smoother device operation, fewer disruptions, and secure data.

- Extended Lifespan: Like regular exercise for health, optimizing extends the connector’s lifespan, giving your devices a longer and healthier life.

- Cost Savings: Fewer signal issues mean less troubleshooting and lower repair costs, offering savings and a more reliable digital experience.

Overview of PI-259 Connectors

Understanding Different Types of PI-259 Connectors

To boost performance, grasp diverse PI-259 Connector types:

- SMA Connectors: Versatile, varying sizes, durable.

- BNC Connectors: Quick, secure radio, TV, military use; unique bayonet coupling.

- TNC Connectors: Improved stability, threaded coupling based on BNC.

- N-Type Connectors: High-frequency, minimal signal loss; wireless communication, RF testing.

- F-Type Connectors: Easy to install, reliable for cable TV and satellites; common in daily setups.

- MCX and MMCX Connectors: Compact, ideal for cell phones, GPS; good performance, space-saving.

- UHF Connectors: Threaded coupling, older equipment; specific applications today.

- Mini-UHF Connectors: Smaller, compact, reliable connections; space-saving solution.

- 7/16 DIN Connectors: High power-handling; telecom base station applications.

- RP Connectors: Gender-reversed, meeting regulatory needs in specific applications.

Consider frequency, power handling, and environment. Whether a robust outdoor connection, a space-saving portable option, or a high-frequency wireless solution, a PI-259 variant suits your needs.

Evolution of PI-259 connectors

PI-259 connectors evolved, originating in 20th-century radio communication. Initially, for reliable radio signal transfer, they now serve diverse industries like telecom, broadcasting, aerospace, and military communication. They are vital for maintaining signal quality, especially in high-frequency signals.

Today, PI-259 connectors ensure widespread Wi-Fi, clear TV, and seamless phone calls.

Basic Principles of PI-259 Connector Performance

Contact Resistance Impact on Signal Quality

Contact resistance within PI-259 connectors quietly undermines signal quality, causing disruptions like crackling and fading during phone calls. This issue arises from compromised contact points.

Contact Resistance Explanation

Resistance occurs at inner conductor junctions in the connector. Even minimal resistance, measured in milliohms, can harm high-frequency signals.

Signal Quality Impact

Contact resistance leads to signal degradation, causing loss, increased noise, and distortion. Wi-Fi routers may experience slower data transfer, while TVs suffer pixelation and poor reception.

Addressing Contact Resistance

Combatting contact resistance is vital. Techniques like cleaning, lubrication, using quality materials, and proper assembly maintain optimal contact, ensuring signals flow freely.

Importance of Impedance Matching

Like tuning instruments for harmony, impedance matching in PI-259 connectors synchronizes signals, preventing reflections and maintaining quality.

Understanding Impedance

Impedance, combining resistance and reactance, reflects the ability to store or release energy. PI-259 connectors have a specific impedance (usually 50 or 75 ohms) to match cables and components.

Signal Quality Impact

Mismatched impedance leads to reflections, causing signal loss, interference, and distortion. Poor TV reception, slow internet speeds, and degraded signal quality may result.

Mitigating Impedance Mismatches

Prioritize impedance matching by choosing connectors and cables with matching characteristics. Use transition components like attenuators for different impedances to ensure signal flow harmony.

Analyzing Losses and Mitigation Strategies

Understanding and mitigating signal losses are crucial for optimal PI-259 connector performance.

Identifying Loss Sources

Conductor resistance, dielectric losses, skin effects, and radiation losses contribute to signal losses. Material properties and connector design impact high-frequency signals.

Mitigation Strategies

Enhance performance with low-loss connectors, top-notch cables, meticulous assembly, regular maintenance, and an understanding of acceptable losses for high-frequency applications.

Techniques for Measuring Performance

Assessing PI-259 connector performance ensures adherence to quality standards.

Key Parameters

Evaluate return loss, insertion loss, and VSWR using specialized tools like vector network analyzers.

Interpreting Results

Deviations from expected values signal issues. Results guide adjustments for enhanced performance and optimal signal quality. Accurate measurement is the first step toward peak connector performance.

Advanced Techniques for Optimizing PI-259 Connector Performance

Optimal Materials and Design

Choose copper or silver for PI-259 connectors; they balance cost and conductivity. Use PTFE for dielectric insulators in high-frequency applications. Outer conductors like brass, aluminum, or stainless steel provide strength and electromagnetic shielding. Connector bodies are typically brass or aluminum.

Consider the design’s shape, contact points, and size concerning impedance, signal reflection, and suitability for specific applications. Enhance conductivity by incorporating gold-plated contact points.

Connector Assembly Techniques

Soldering Mastery

Maintain the right soldering temperature to prevent damage. Apply flux for clean joints. Take your time for precision and avoid excess solder.

Effective Crimping

Choose high-quality crimping tools. Match the crimping die to the connector and cable dimensions. Apply consistent pressure for a robust connection.

RF Shielding and Grounding

Minimizing Interference

Choose connectors with built-in shielding. Use properly shielded cables. Enclose connectors and sensitive components in shielded enclosures.

Ensuring Signal Integrity through Grounding

Ensure a single ground point for all components. Use grounding techniques like star grounding. Implement grounding straps for a low-resistance path.

Thermal Management

Heat Dissipation Awareness

Select connectors with suitable power handling capability. Ensure airflow around connectors, especially in enclosed spaces.

Thermal Protection Strategies

Implement temperature monitoring. Use heat sinks for effective heat dissipation, particularly in connectors exposed to high power levels.

Integrating advanced techniques in material selection, design, assembly, shielding, grounding, and thermal management enhances PI-259 connectors, ensuring maximum signal quality and reliability in various applications.

Testing, Validation, and Performance Analysis

The Role of Testing in PI-259 Connector Optimization

Testing is the litmus test for excellence in achieving optimal PI-259 connector performance. It ensures connectors deliver flawless real-world performance.

Why Testing Matters?

Testing means thoroughly evaluating functionality, reliability, and adherence to performance standards. It identifies potential issues before real-world use, preventing uncertainties in the optimization process.

Key Aspects of Testing

- Functionality: Verify seamless performance, including signal transmission, impedance matching, and resistance levels.

- Durability: Test resilience to wear, corrosion, and environmental factors for prolonged reliability.

- Signal Integrity: Evaluate signal quality before and after connection, identifying and addressing any degradation.

Recommended Testing Equipment, Tools, and Techniques

Equip yourself for precision testing with the following tools:

- Vector Network Analyzer (VNA): Measures return loss, insertion loss, and VSWR for a comprehensive performance picture.

- Time Domain Reflectometer (TDR): Identifies impedance mismatches or discontinuities, aiding troubleshooting.

- Cable and Antenna Analyzer: Assesses cable and antenna health, optimizing the entire RF system.

- Continuity Tester: Checks conductor continuity, ensuring no breaks or short circuits.

- Environmental Testing Chambers: Simulate real-world conditions to assess connector performance in varied environments.

Interpreting Test Results and Implementing Adjustments

Deciphering Test Results

- Comparative Analysis: Compare results against benchmarks and industry standards, identifying potential issues.

- Trend Analysis: Look for patterns in the data, addressing consistent issues across multiple tests.

- Root Cause Analysis: Delve deeper to identify material, design, or assembly issues causing anomalies.

Implementing Adjustments

- Iterative Testing: Make changes based on identified issues, conducting iterative testing for gradual performance improvement.

- Collaboration: Involve experts from different domains to collectively address specific challenges revealed in tests.

- Documentation: Maintain detailed records of adjustments and their impact on future optimizations and troubleshooting.

Common Issues and Challenges with PI-259 Connectors

Identifying Problems

PI-259 connectors excel in signal transmission, but they’re not flawless. Knowing their common problems is the key to keeping them at their best.

Contact Resistance

Issue

Worn or dirty connector contact points.

Challenge

Spotting and fixing contact resistance to keep signals clear.

Impedance Mismatch

Issue

Mismatched impedance between connectors or cables.

Challenge

Ensuring a proper match to prevent signal problems.

Signal Loss

Issue

Natural signal loss in high-frequency situations.

Challenge

Reducing losses to keep signals intact.

EMI Interference

Issue

Electromagnetic interference, disrupting signals.

Challenge

Using effective shielding to minimize interference.

Poor Connector Assembly

Issue

Faulty soldering or crimping, causing weak connections.

Challenge

Using precise assembly for highly reliable links.

Impact on Signal Quality

Understanding how these problems affect signals is vital for solving them effectively.

Degraded Signal Quality

Contact Resistance: Causes noise, distortion, or dropped signals.Impedance Mismatch: Leads to disruptions and lower signal quality.

Increased Signal Loss

Inherent Losses: Cumulative losses weaken signals, especially in high-frequency applications.

Interference and Distortion

EMI Interference: Adds unwanted noise or distortion, disrupting signals.

Reliability Issues

Poor Connector Assembly: Unreliable connections risk signal interruptions or failure.

Real-World Consequences

Overlooking PI-259 connector optimization has real-world repercussions affecting users and systems.

Unreliable Communication

Signal Quality Issues: Incomplete calls, distorted audio, or pixelated video.

Slow Data Transfer

Signal Losses: Reduced data transfer rates in Wi-Fi or broadband connections.

System Downtime

Reliability Issues: More downtime from unreliable connections affecting critical systems.

Increased Maintenance Costs

Poor Connector Assembly: Frequent maintenance due to suboptimal assembly, leading to higher costs.

Compromised User Experience

Signal Quality Degradation: Frustrating experiences in streaming, broadcasting, or data-intensive tasks.

Long-Term Damage

Cumulative Impact: Unresolved issues can cause irreversible damage to connectors and connected components.

Best Practices for Sourcing PI-259 Connectors and Components

1.Choosing Reliable Suppliers involves a crucial Reputation Check, prioritizing established industry players.

- Experience is key, favoring suppliers with a track record, especially in PI-259 connectors.

- Ensuring Standards Compliance is vital, confirming relevant certifications and adherence to regulations.

- Scalability and Communication are critical, recommending partners with open communication and adaptability to specific needs.

2.Quality Control and Certification emphasize thorough assessment.

- Inquire about Control Processes during manufacturing, focusing on rigorous testing for key parameters.

- Encourage ISO Certification, particularly ISO 9001 and 14001, and confirm compliance with Industry Standards and RoHS directives.

- Traceability is essential, favoring suppliers with batch and lot number transparency.

3.Spotting Counterfeits involves a strategic approach.

- Utilize Authorized Channels, sourcing from verified distributors or manufacturers.

- Emphasize Consistency in Packaging and Labeling, checking print quality for authenticity.

- Request Certificates of Conformity, independently verified.

- Rigorous Testing, including random sampling and third-party testing, ensures components meet specified parameters.

- Stay Informed through regular industry publication checks for a proactive sourcing strategy.

VIII. Advanced Techniques for Assembling PI-259 Connectors

Step-by-Step Guide to Proper Connector Assembly

For optimal performance from PI-259 connectors, follow this detailed guide.

- Begin by gathering the necessary tools, including the connector, cable, soldering iron, solder, and crimping tool.

- Strip the cable according to guidelines for conductor and insulation length, inspect the connector for defects, and employ advanced soldering or a quality crimping tool.

- Apply heat-shrink tubing for insulation, assemble components meticulously, and tighten them appropriately.

- Conduct continuity checks and visually inspect the final assembly, documenting the process for troubleshooting or improvements.

Equipping Your Workshop: Selecting Tools for Precision Assembly

Precision is key when assembling PI-259 connectors.

- Choose a temp-controlled soldering iron, a high-quality crimping tool with interchangeable dies, a reliable heat gun with variable settings, and a digital multimeter for continuity checks.

- Use an adjustable cable stripper, include a torque wrench for tightening, and employ inspection tools like magnifying glasses or microscopes.

- Document the assembly process with cameras or digital tools.

Steering Clear of Pitfalls: Avoiding Common Assembly Mistakes

To ensure reliable connectors and robust signal transmission, be aware of common mistakes.

- Use a precision cable stripper, control heat during soldering, and follow guidelines for crimping to prevent issues.

- Use a torque wrench to avoid damage or misalignment, conduct continuity checks, and take time for a thorough visual inspection.

- Keep detailed documentation for future reference during troubleshooting or improvements.

Following this guide ensures the reliable performance of PI-259 connectors in electronic systems.

Conclusion

Ensuring PI-259 connectors work well is vital for a smooth digital experience. Understand the different types, basic ideas, and advanced methods to make their signals better, devices more reliable, and devices last longer.

Testing and fixing common problems help a lot, stopping things like bad communication and expensive repairs. Getting parts from the best suppliers like Promax Pogo Pin Electronics Technology Co., Ltd. and assembling things the right way also make the connectors last longer and work well.

Following these tips means people can have better signals, devices that run smoothly, and a more dependable digital experience.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days