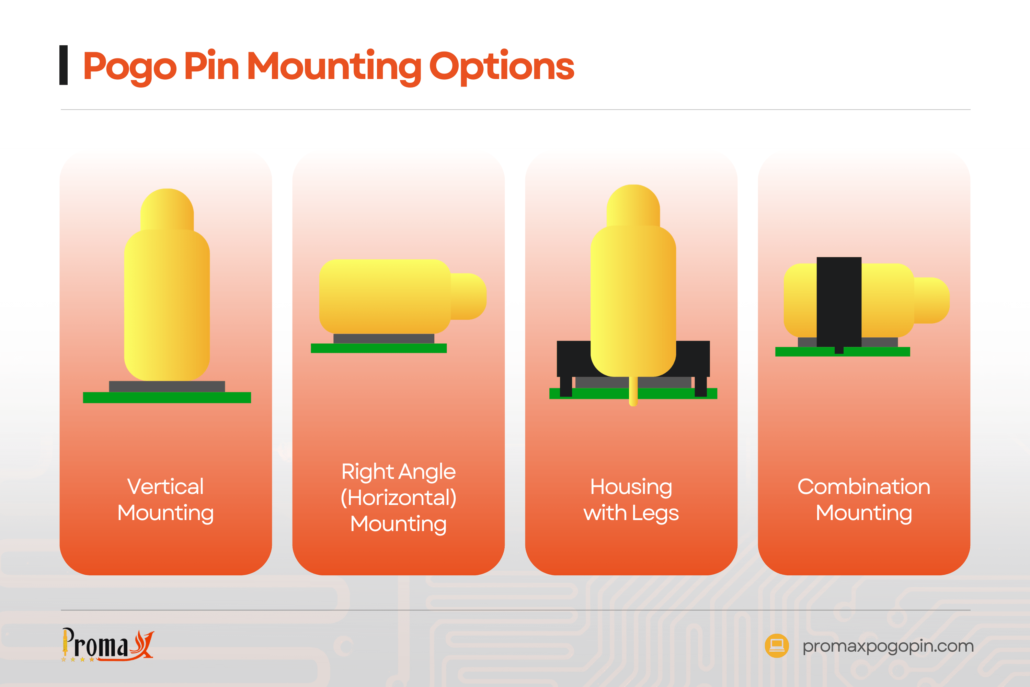

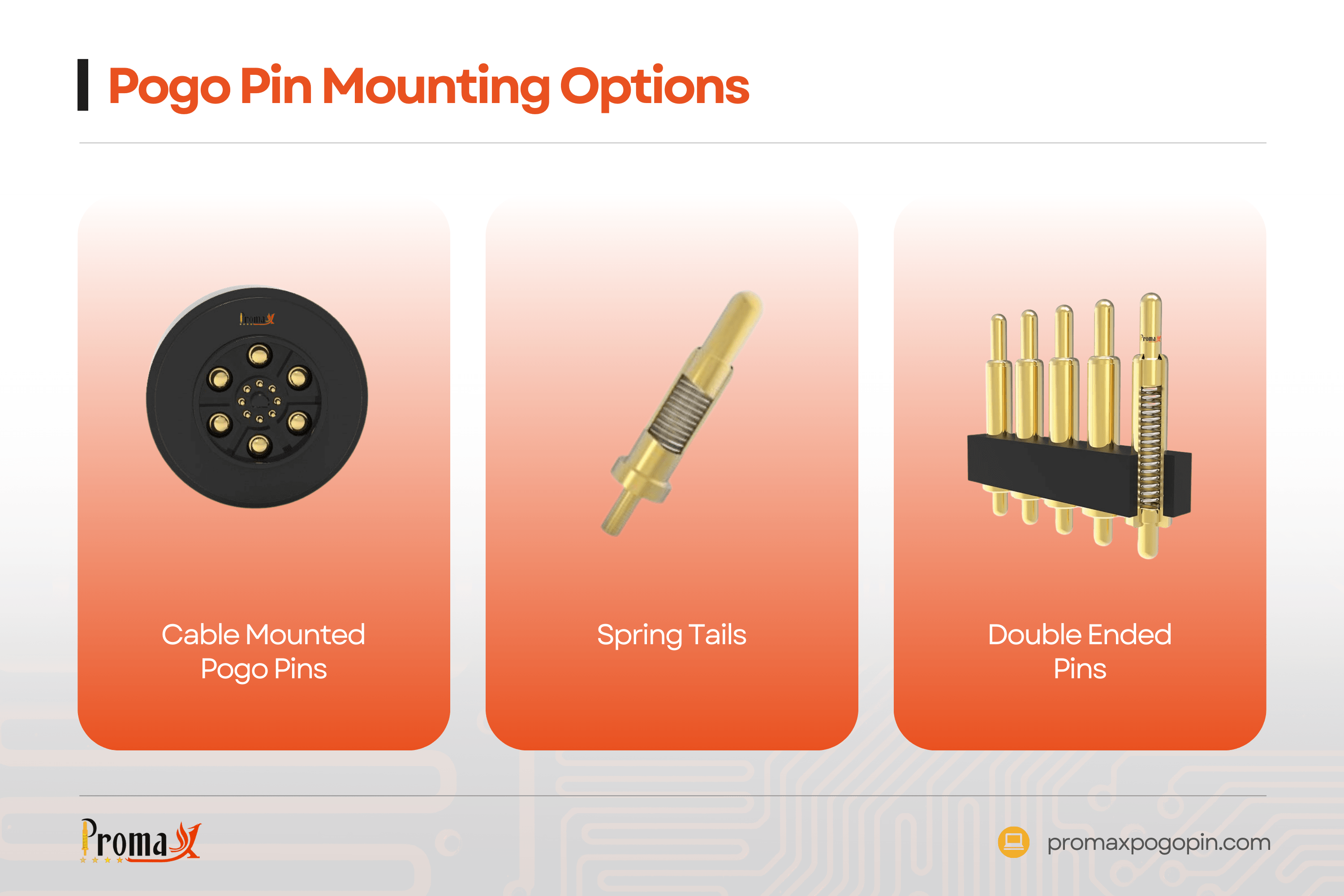

In this guide, Promax Pogo Pin breaks down different mounting options for pogo pin contacts, specifically vertical mounting, horizontal mounting, housing with legs, combination mounting, cable mounted, spring tails, and double ended pins.

Spring loaded pogo pins, known for their reliability and adaptability, are essential in creating durable electrical connections in devices ranging from consumer electronics to advanced testing equipment. Understanding the different mounting techniques can help you improve the performance and longevity of these connectors. Here are seven mounting options available for pogo contact pins.

Key Takeaways

- Pogo pin contacts are essential for reliable electrical connections in various applications.

- Vertical mounting is a common method that offers stability and ease of assembly.

- Right angle mounting saves space while maintaining effective connectivity.

- Housing with legs improves durability and alignment during use.

- Cable-mounted pogo pins provide flexibility for dynamic applications.

Mounting Options Overview

We’ve summarized the main pogo pin mounting options for spring-loaded connectors below:

| Mounting Option | Description | Benefits |

| Vertical Mounting | Pins inserted vertically for direct soldering |

|

| Right Angle Mounting | Connectors extend horizontally from PCB |

|

| Housing with Legs | Pins secured in a housing for stability |

|

| Combination Mounting | Combines vertical and right angle features |

|

| Cable-Mounted Pins | Attached via flexible cables for mobility |

|

| Spring Tails | Provides extra compression for better contact | Reliable in high-vibration environments |

| Double-Ended Pins | Contact points at both ends for flexibility |

|

Vertical Mounting

In vertical mounting configurations, pogo pins are inserted vertically into designated holes on the PCB, allowing for direct soldering. This method ensures a secure and stable connection, making it great for applications where durability is important. Vertical mounting is one of the most straightforward methods for integrating spring-loaded pogo pins into printed circuit boards (PCBs). The vertical orientation also allows the pins to compensate for minor misalignment, which is essential in environments that are prone to mechanical shock or vibration.

Vertical mounting allows for easier automated assembly processes. Automated soldering techniques can be used to ensure consistent quality across multiple units. The design allows for a small amount of space on the PCB while providing reliable electrical connections that can withstand a minimum of 50 g shock and 10 g vibration. This makes vertical mounting suitable for consumer electronics and portable devices where space is limited, but reliability is critical.

Right Angle (Horizontal) Mounting

In right angle or horizontal mounting of pogo pin connectors, the spring-loaded connectors extend horizontally from the PCB, allowing for a smaller design without cutting off connectivity. This orientation is helpful in various applications where space efficiency is important or where there are height restrictions, such as in slim electronic devices or wearable devices.

The right angle design also simplifies the mating process by aligning the pins with corresponding receptacles at an exact angle. This reduces insertion force and minimizes wear on both the connector and the mating surface. Right angle mounted pogo pins can also be configured to support high current loads because they can distribute stress more evenly across the connection points, leading to high durability and performance.

Housing with Legs

Integrating pogo pins within a housing that includes legs provides improved stability and alignment during operation. This method involves securing pogo pins within a plastic or metal housing that supports them as they make contact with their mating surfaces. The legs help maintain proper alignment, even with shock or vibrations, ensuring that the electrical connection remains intact.

This mounting option is fantastic for applications requiring frequent mating cycles, as it reduces wear on both the pogo pins and the PCB. The housing also protects the pins from environmental factors such as dust and moisture, which can bring down performance over time. By using housings made from thermoplastic materials, manufacturers can achieve high durability while maintaining low-resistance connections essential for efficient current flow.

Combination Mounting

Combination mounting techniques use the strengths of various methods to create versatile, interconnected solutions. By combining features from vertical and right angle mountings, manufacturers can design connectors that offer both stability and flexibility. For example, a combination approach might involve using vertical pogo pins housed within a casing that allows them to pivot slightly during mating.

This flexibility is ideal in use cases where precise alignment cannot always be guaranteed due to manufacturing tolerances or environmental factors. Using different mounting styles can make assembly easier because it lets manufacturers pick the best setup for each specific application requirement. This adaptability ensures that spring-loaded pogo pins can meet diverse demands across various industries.

Cable Mounted Pogo Pins

Cable-mounted pogo pins are attached via flexible cables with solder cups at their ends. This setup allows the pins to connect to various components without being fixed in place. With cable-mounted pins’ flexibility, devices can handle movement without compromising electrical connectivity. As a result, these pogo pins are a particularly innovative solution for applications requiring mobility or dynamic connections.

Applications such as robotic systems or wearable technology can benefit from cable-mounted spring-loaded pins because they allow for more freedom of movement while maintaining reliable electrical connections. This setup minimizes stress on solder joints since the cables can absorb some of the mechanical forces that are applied during operation. Cable-mounted configurations are ideal for environments where traditional rigid connections would fail due to constant motion.

Spring Tails

Spring tails provide extra compression capabilities at their tips, which improves the functionality of pogo pin connectors. These spring-loaded features enable better contact with mating surfaces by compensating for minor misalignment during assembly or operation. Spring tails are often used in high-vibration environments where traditional connectors might struggle to maintain reliable connections.

The added spring force helps ensure that even when subjected to shock or vibration, the electrical connection remains intact without a lot of degradation over time. This feature makes spring tails a great choice for demanding applications such as automotive electronics or industrial machinery where reliability is non-negotiable.

Double Ended Pins

Double-ended pogo pins feature contact points at both ends of a single pin structure. This design allows for flexible mating options and simplifies assembly processes, as one pin can serve multiple functions or connect to different components simultaneously. Double-ended configurations are helpful in compact designs where space is at a minimum.

Also, double-ended pins can improve reliability by providing redundancy. So, if one end experiences wear or failure, the other end might still function effectively. This feature is useful in high-cycle applications such as automated testing equipment, where frequent mating and unmating occur.

Promax Pogo Pin: Highly Skilled Pogo Pin Manufacturers

Electronic devices can have a number of demanding application requirements, so choosing the appropriate mounting option for pogo pin contacts can significantly impact performance and reliability.

Whether you decide to go for vertical mounting or explore dynamic solutions like cable-mounted configurations, understanding each method’s benefits is essential for achieving the best results in electronic designs. Luckily, Promax Pogo Pin is here to help you throughout the process.

If you’re looking for experienced guidance or high-quality pogo pins customized to your specific needs, get in touch with Promax Pogo Pin!

Pogo Pin Mounting Options for Spring Loaded Connectors FAQs

How do you secure pogo pins?

To secure pogo pins, you can use through-hole mounting or surface mount techniques (SMT). With a compliant connector giving you flexibility and stability to the pins during operation, you’re good to go. Also, machine processes can help insulate connections and ensure a solid fit.

What is the standard distance between pins?

The standard distance between pogo pins usually ranges from 1.0 mm to 2.54 mm, depending on the application requirements. For high-density applications, such as USB connectors, pins offer compact spacing while maintaining performance. This ensures that spring-loaded contacts function effectively without interference. When designing, it’s important to know that when your pins have plug-in features, you might need slightly greater spacing for ease of connection.

How do you attach pogo pins?

Pogo pins can be attached using SMT for precise placement on PCBs, or by inserting them into holes for through-hole mounting. Magnetic pogo pins provide easy alignment during assembly, making installation efficient. Ensure that the plunger mechanism is correctly positioned for the best probe functionality.

Back to top: Pogo Pin Mounting Options for Spring Loaded Connectors

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days