Electrical connectors have undergone a remarkable transformation in recent years. It’s due to the advancements in robotics and automation. Robotics and automation technologies have made manufacturing faster, more efficient, and more dependable. It enables manufacturers to meet the ever-increasing demand for high-quality goods.

For robotics and automation systems to operate, electronic components must communicate seamlessly. It is where pin headers come in. These components are crucial for reliable and efficient data transmission between electronic circuits.

This article delves into the pin headers in robotics and automation, exploring their advantages and other relevant aspects. It is crafted to cater to all expertise levels, from novice to seasoned professionals, in the industry.

You’ll get actionable insights and valuable information to choose suitable pin headers for your needs.

So, let’s unravel the indispensable role of pin headers in robotics and automation. And discover how these components have transformed the manufacturing industry.

What are Pin Headers?

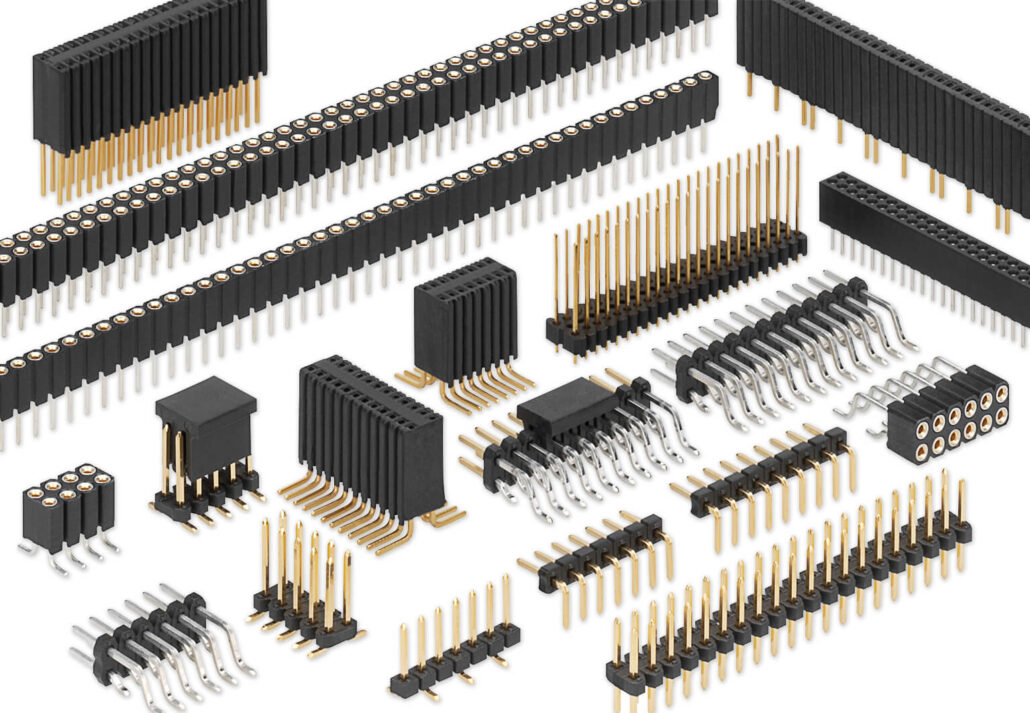

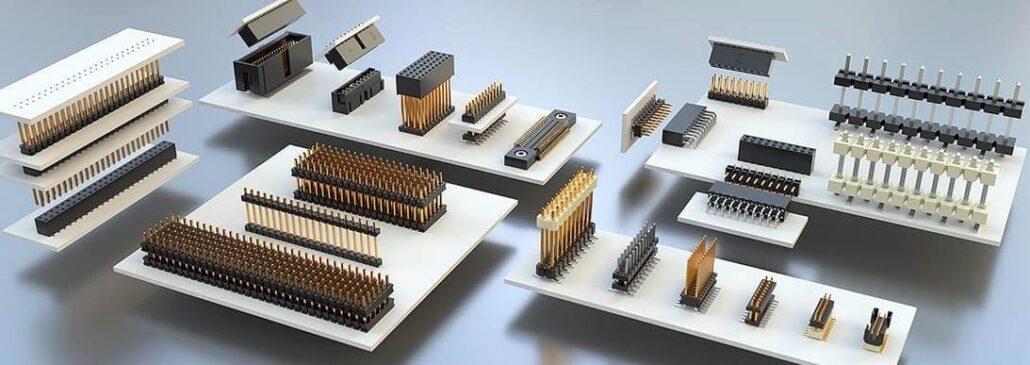

Pin headers are electronic components that provide a physical interface between two or more electronic circuits. They consist of a plastic housing and pins or sockets that protrude from the bottom of the housing. They come in different sizes, shapes, and configurations based on the application.

Types of Pin Headers

There are several types of pin headers based on design, features, and functionality. The most common types of pin headers include:

-

Straight Pin Headers

Straight pin headers, the most common type, consist of a straight row of pins usually spaced apart. They have various pitch sizes and offer many configurations.

Straight pin headers can be used for applications like PCBs, prototyping, and others.

-

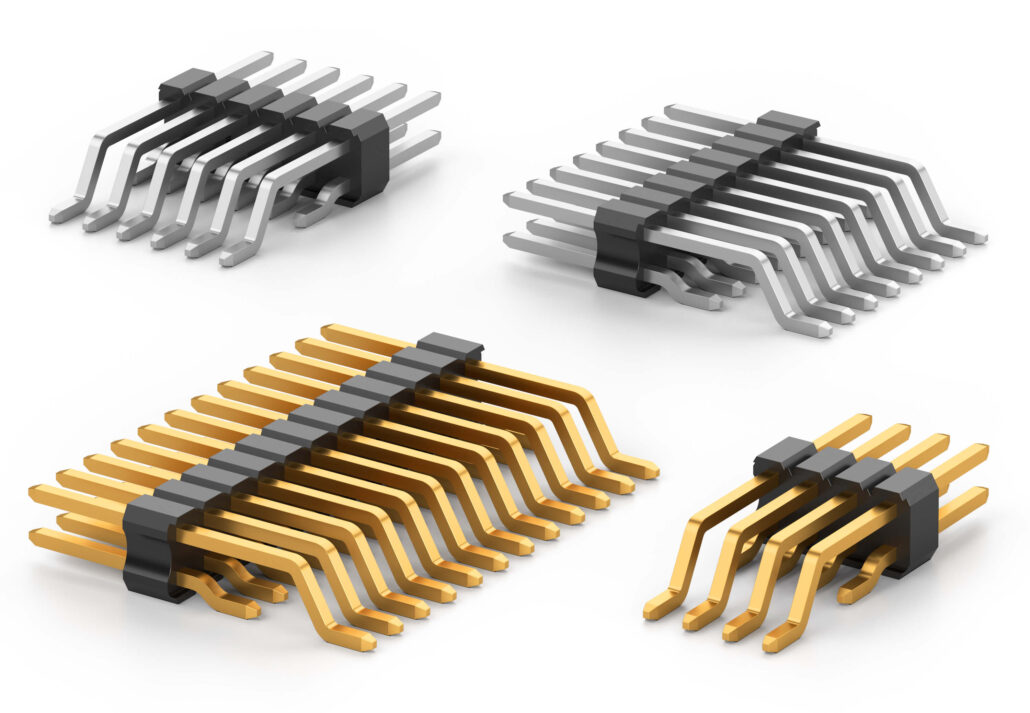

Right-Angle Pin Headers

Right-angle pin headers are like straight pin headers but with a 90-degree bend to be mounted vertically on the edge of a printed circuit board.

They are the go-to solution in scenarios where horizontal mounting is unfeasible with limited space.

-

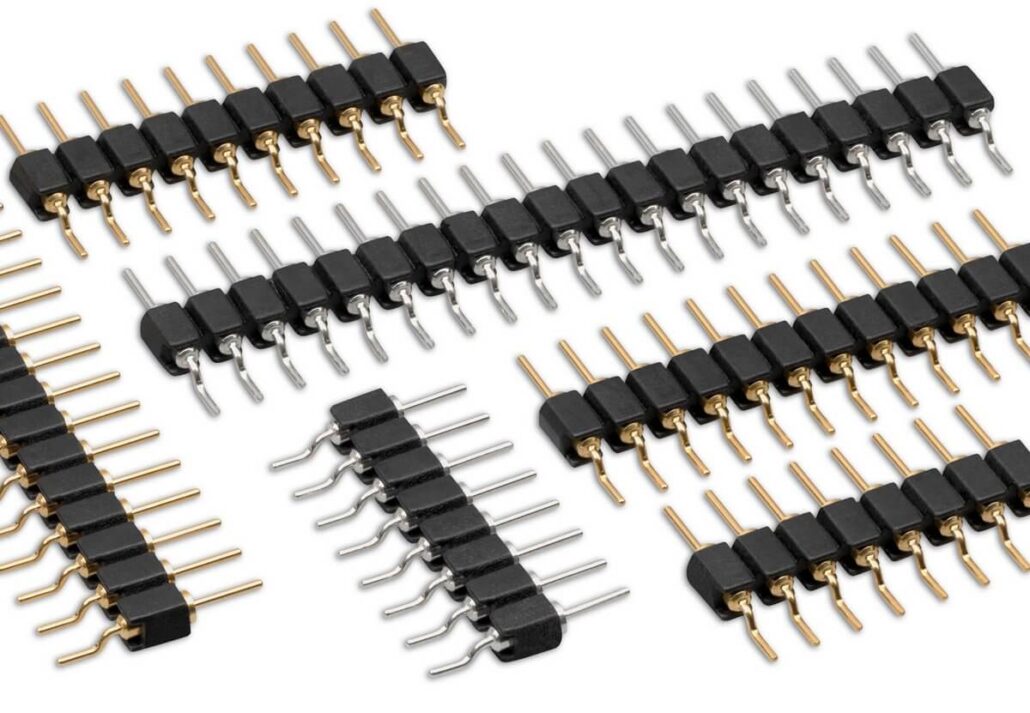

SMD Pin Headers

SMD pin headers are designed for use in SMD applications where the components are directly mounted onto the surface of the circuit board.

SMD pin headers have many sizes and configurations and come in straight and right-angle versions.

They are used in consumer electronics, computer peripherals, and other compact electronic devices.

-

Box Pin Headers

Box headers, or shrouded pin headers, are used for a secure connection where vibration or movement is a concern. They feature a plastic shroud to cover the pins, protecting against damage or short circuits.

Where compactness and reliability are paramount, box headers find frequent uses, particularly in high-density applications.

-

IDC Pin Headers

Insulation Displacement Connector (IDC) pin headers connect to ribbon or flat cables. They use a particular tool to insert the wires into the connector, which cuts through the insulation and securely links with the conductor.

IDC headers see widespread use in electronic devices such as printers, disk drives, and other related applications.

-

Through-Hole Pin Headers

Through-hole pin headers are traditional for electronics manufacturing. They have pins that go through the circuit board and are soldered on the other side to make a secure connection.

Through-hole pin headers are robust and reliable. It makes them ideal for industrial and automotive applications.

-

Dual Row Pin Headers

Dual-row pin headers are like straight-pin headers but have two rows of pins instead of one.

They are frequently used in applications requiring multiple connections between circuit boards.

-

Pogo Pin Headers

Pogo pin headers use spring-loaded pins to establish a reliable connection. They find frequent applications in test and measurement contexts involving periodic connection and disconnection.

-

Coaxial Pin Headers

They use a coaxial cable to make a secure connection, providing reliable transmission of signals.

Coaxial pin headers are designed for high-frequency applications such as antennas, RFID readers, and other wireless communication devices.

-

FFC/FPC Pin Headers

FFC/FPC headers use a special connector that clamps onto the cable to make a secure connection.

Their applications include LCDs, touch screens, other consumer electronics, etc.

The Benefits of Pin Headers in Robotics and Automation

The advantages of using pin headers expand well beyond mere connectivity. They can substantially enhance the system’s overall efficiency and performance.

-

Reliable and Efficient Connectivity

Pin headers offer reliable and efficient connectivity between electronic circuits. They rely on pins that connect directly to a circuit board, ensuring a secure and stable connection. As such, they prevent data loss or signal interference, leading to a more accurate and efficient system.

-

Transmit Data and Signals Over Long Distances

They are great at connecting different circuits and components so that information and signals can travel long distances. It makes them super useful for large and complicated robotics and automation systems.

-

Cost-effective and Time-saving

Pin headers provide a cost-effective and time-efficient connectivity option compared to other alternatives. It makes them optimal for businesses looking to optimize their systems while reducing expenses.

-

Versatility and Adaptability

They are suitable for a wide array of electronic devices and components, making them universal connectivity options. Additionally, they can withstand harsh conditions, ensuring consistent performance.

-

Potential For Reducing Errors and Increasing Efficiency

The use of pin headers has the potential to diminish errors and boost efficiency in robotics and automation systems. The secure connections resist vibration and shock, ensuring consistent performance in harsh environments.

-

Easy Installation and Maintenance

Pin headers are designed to be straightforward to connect and disconnect, making it easy to replace or repair components without complex wiring or soldering. This simplifies system maintenance, reduces downtime, and helps it perform optimally.

-

Compatibility

Pin headers are versatile connectors to connect a wide range of electronic circuits, such as sensors, actuators, controllers, and power supplies. This flexibility makes them great for businesses that require the ability to connect many electronic devices and components.

-

Modular Design

Pin headers facilitate modular design, allowing for easy customization and scalability of robotic and automation systems. They can be effortlessly integrated into a system without complex wiring to let you easily install or remove components. This modular design promotes scalability, enabling the system to expand as the business grows.

-

Reduced Signal Noise and Interference

Pin headers are offered in shielded and insulated versions, reducing signal noise and interference. The shielding and insulation safeguard the pins from external interference, ensuring signals are transmitted accurately and without data loss.

How to Choose the Right Pin Headers for Your Needs?

Several critical factors must be taken into account when selecting the appropriate pin headers to ensure effective connectivity between electronic components in your robotics and automation projects. These factors include:

- Pitch: The pitch of a pin header refers to the distance between each pin, which determines the type of components it can connect. Choose a pin header with a pitch that matches the circuit board or device you want to connect it to.

- The number of contacts: The number of pins or contacts you need will depend on your required connections. Choose a header with enough pins to connect all the components you need.

- Gender: The male headers have pins extending outwards, while the female headers have slots that accept the male pins.

- Mounting: Pin headers can be mounted on the circuit board in various ways, such as through-hole or surface mount. The mounting method you choose will depend on the board and the application.

- Current rating: Pin headers have a maximum current rating that establishes the amount of power they can manage. Select a pin header with a current rating that meets your application’s power demands.

- Operating temperature: Pin headers can operate within a specific temperature range. Choose a header that can handle the temperatures present in your application.

- Material: The choice of material for constructing pin headers, which can be plastic, metal, or ceramic, is based on the particular needs of the application, such as the level of resistance required against heat or vibration.

- Cost: Choose a pin header that fits your overall project budget while meeting your required durability, reliability, and performance.

Pin Header Best Practices

-

Proper Installation and Maintenance

- Use high-quality from reputable manufacturers and suppliers. Or low quality can result in unreliable performance.

- Before installation, check for proper alignment of the pins to avoid damage to the header or the mating connector.

- Use the appropriate tool for crimping or soldering the pins to ensure a secure connection.

- Regularly inspect pin headers for signs of damage, such as bent or broken pins, which can cause connection problems.

- To prevent contamination, use a clean and dry cloth to remove dust or debris from the pins and connectors.

-

Tips For Avoiding Common Mistakes

Here are some common issues to avoid with proper planning and installation techniques.

- Ensure the pins are correctly soldered to prevent poor-quality connections, which can result in signal loss, intermittent connections, or system failures.

- Avoid over-tightening the screws that secure the header to prevent damage or misalignment.

- Proper header placement is vital to prevent damage to the header or the board.

- Use proper strain relief techniques to prevent stress on the header and ensure a reliable connection.

Future Developments and Trends

As robotics and automation technology evolves, pin headers undergo developments and improvements. Here are some of the potential future trends.

- There may be a need for smaller and more compact pin headers as robotics and automation systems become more compact.

- Pin headers may need to be designed to handle higher data rates with the growing demand for higher speed and bandwidth in automation systems.

- Pin headers are expected to feature advanced materials such as ceramics and composites with better heat, moisture, and vibration resistance.

- Pin headers may also be designed to integrate with other technologies, such as wireless communication, to enable more advanced robotics and automation systems.

Conclusion

To sum up, pin headers are essential in robotics and automation. They offer a reliable and efficient method of connectivity. It allows seamless communication between various parts of a system. Whether you’re a robotics expert or a newbie, understanding the importance of pin headers is critical. With their simple design and versatility, incorporating pin headers into your designs will help take your automation and robotics projects to new heights. So, put your newfound knowledge to use and unlock the vast potential of pin headers!

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days