A pogo pin is a spring-loaded electrical connector used in different electronic devices and testing equipment. These flexible components, also known as spring-loaded pins, play an important role in establishing reliable electrical connections between different parts of a circuit or between separate devices.

In the world of electronics, pogo pins have become really popular, because they can maintain consistent contact even in the most challenging environments. Promax Pogo Pin is a highly skilled pogo pin manufacturer, and we want to make sure you’re making informed decisions about these pins. In this article, we discuss the pogo pin meaning, the different types of pogo pins, their components, applications, and more.

Key Takeaways

- Pogo pins are spring-loaded connectors that ensure reliable electrical contact.

- These pins are made up of a plunger, spring, and barrel assembly.

- They come in different types and sizes to suit different applications.

- Pogo pin connectors are widely used in electronics testing and consumer devices.

- Pogo pins offer benefits such as durability, flexibility, and space-saving design.

What is a Pogo Pin?

Pogo pins are specialized electrical connectors used to establish temporary or permanent connections between two circuits or devices. These pins get their name from their resemblance to the spring mechanism found in pogo sticks, as they use a similar system of compression and extension. Pogo pins are also referred to as spring-loaded pins or contact probes.

Pogo pins are PCB pins that work as an important component in many electronic assemblies. They are made of a plunger that moves inside a barrel, with a spring providing the necessary force to maintain contact. This design allows pogo pins to handle different variations in height and surface irregularities, ensuring a stable and reliable electrical connection.

Types of Pogo Pins

There are two main types of pogo pins: spring-loaded and friction-fit. Spring-loaded pogo pins have a spring inside that keeps the connection between the two PCBs secure. Friction-fit pogo pins do not have a spring, but instead rely on the friction between the pin and the PCB to keep the connection in place.

However, there are a few other types of pogo pins designed to meet specific requirements in different applications. Here are some other common types:

| Type | Design | Application |

|---|---|---|

| Standard Pogo Pins | Basic, widely used | General-purpose applications, e.g., consumer electronics like phones, tablets, and wearables |

| High-Frequency Pogo Pins | Optimized for high-frequency data transfer and signal integrity | Applications requiring high-frequency data transfer, e.g., RF modules, high-speed networking devices, and testing equipment |

| High-Current Pogo Pins | Built to handle higher current loads | Power connections, e.g., electric vehicle (EV) chargers, battery packs, and high-power LED lighting systems |

| Waterproof Pogo Pins | Designed to handle moisture and liquid exposure | Outdoor or water-resistant devices, e.g., smartwatches, underwater sensors, and ruggedized handheld devices |

| SMT Pogo Pins | Surface-mount technology (SMT) | Easy integration into PCBs for automated assembly processes, e.g., smartphones, laptops, and IoT devices |

Your choice of pogo pin type depends on factors like the required current carrying capacity, frequency of use, environmental conditions, and the specific application requirements.

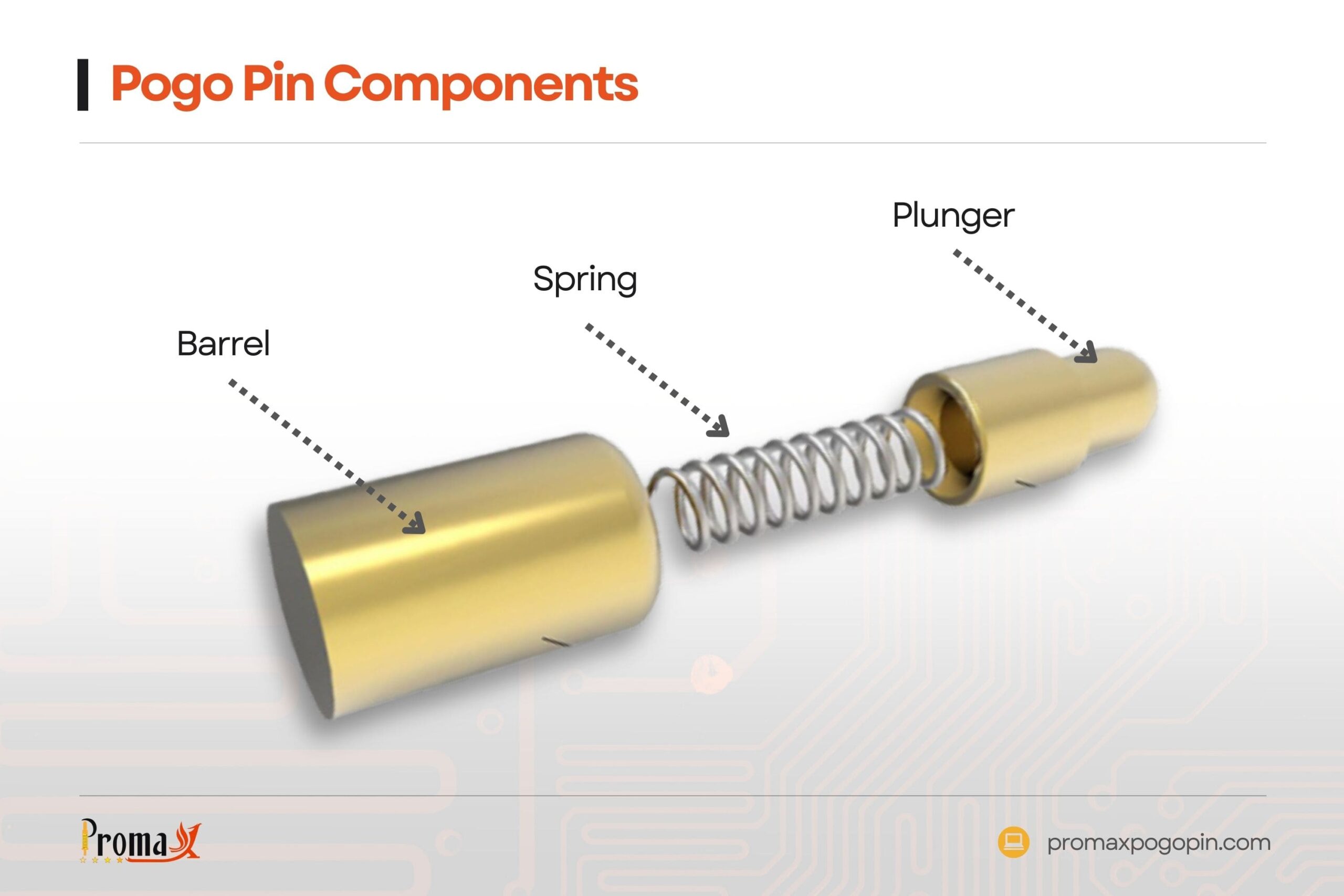

Pogo Pin Components

A normal pogo pin has three main components: the plunger, the spring, and the barrel. Each of these parts is important for the functionality and performance of the pogo pin. Let’s dive into spring-loaded pogo pins in more detail:

- Plunger: The plunger is the moving part of the pogo pin that makes direct contact with the mating surface. It is usually made of brass or copper and may have gold plating or other conductive materials that enhance the pogo pin’s conductivity and durability.

- Spring: The spring provides the force necessary to maintain contact between the plunger and the mating surface. It keeps the plunger pressed against the target even when it is subjected to vibration or movement.

- Barrel: The barrel houses the plunger and spring, providing structural support and guiding the plunger’s movement. The barrel also acts as the outer contact point for the pogo pin assembly. It’s designed to keep the plunger in place and stop the spring from forcing it out when the pin is not locked, as these pins may do that.

These components work together to create a reliable electrical connector that can handle several contact heights and surface irregularities. Moreover, the design of pogo pins allows for a slight gap between the plunger and barrel, which helps accommodate any misalignment or movement when it is being used.

How Do Pogo Pins Work?

Pogo pins work on a simple, but effective, principle that allows them to maintain consistent electrical contact. When a pogo pin is pressed against a mating receptacle or contact plate, this is what happens:

- As force is applied to the plunger, it begins to compress the internal spring.

- The spring compression creates a constant force that pushes the plunger against the mating surface.

- This continuous pressure maintains a stable current flow and reliable electrical connection.

- If there’s any movement or vibration, the spring-loaded mechanism allows the plunger to adjust its position while maintaining contact.

The spring-loaded design of pogo pins makes them really useful in applications where mechanical shock and shaking are common. Even if the connected devices move slightly, the pogo pin’s plunger can extend or retract as needed, which prevents disconnections and ensures uninterrupted data transfer or power supply through the charger.

How to Install Pogo Pins: Quick Guide

Installing pogo pins correctly is important for ensuring the best performance and longevity. Here’s a quick guide to help you through the process:

- Prepare the PCB: Make sure that the PCB has the required plated areas, number of contact points, and cable assembly for the pogo pins. Clean the surface to remove any debris or contaminants.

- Choose the right pogo pin: Select pins that match your PCB’s specifications and application requirements. Think about factors like current capacity, size, and plating material.

- Installation: For through-hole pogo pins, insert the spring force pin into the designated hole on the PCB. Then, solder the pin in place, ensuring a secure connection. For surface-mount pogo pins, apply solder paste to the designated pads on the PCB. Finally, place the pogo pins on the pads using tweezers or a pick-and-place machine and reflow the solder using a reflow oven or hot air station.

- Testing: After installation, test each pogo pin for proper functionality and electrical continuity. Make sure that the plunger moves smoothly and makes good contact with the mating surface.

Proper installation is important in order to maximize the benefits of pogo pins and ensure the stability of the current flow in your electronic devices.

The Applications of Pogo Pins

Pogo pins are used to create reliable connections in electronics testing, consumer devices, board-to-board connections, battery interfaces, and industrial equipment. Key pogo pin functions include testing, charging, data transfer, and modular connectivity.

| Application | Description |

|---|---|

| Testing and Programming | Enables quick, reliable connections in automatic test equipment |

| Consumer Electronics | Facilitates charging and data transfer in devices like smartphones |

| Board-to-Board Connections | Allows removable connections between circuit boards |

| Battery Connections | Ensures secure links between batteries and device circuitry |

| Industrial Equipment | Provides temporary connections in various manufacturing applications |

Let’s examine these pogo pin applications in more detail:

- Testing and Programming: In the electronics testing industry, pogo pins are often used in automatic test equipment to make temporary connections with devices under test. They allow for quick and reliable testing of PCBs and other connector types and electronic components.

- Consumer Electronics: Many smartphones, tablets, and wearable devices use pogo pins for charging and data transfer. These pins enable easy docking and undocking of devices without the need for traditional plug-in connectors.

- Board-to-Board Connections: Pogo pins are used to create a removable connector assembly between different circuit boards in modular electronic systems.

- Battery Connections: In devices with replaceable batteries, pogo pins can provide a secure and reliable connection between the battery and the device’s circuitry.

- Industrial Equipment: Pogo pins are used in various industrial applications where reliable, temporary connections are needed, such as in manufacturing processes or quality control testing.

The flexibility of pogo pins makes them a great choice for a wide variety of applications where reliable electrical connections are important.

The Benefits of Pogo Pins

Pogo pins are durable, flexible, space-saving, reliable, and easy to maintain. These advantages make them a popular choice in the electronics industry:

- Durability: The spring-loaded connector design of pogo pins allows them to handle repeated use without too much wear. This improves the durability and contact resistance of the connection over time.

- Flexibility: Pogo pins can handle different variations in height and surface irregularities, making them great for applications where perfect alignment is difficult to get right.

- Space-Saving: Pogo pins can be arranged in a dense pattern, which allows for many contact points in a small area. This is especially helpful in compact electronic devices.

- Reliable Contact: The constant spring force applied by pogo pins ensures a stable and consistent electrical connection, even in environments that are exposed to vibration or movement.

- Easy Maintenance: Individual pogo pins can often be replaced if damaged, without the need to replace an entire connector assembly.

These benefits make pogo pins a fantastic option for designers and engineers looking to create reliable and efficient electronic devices.

Promax Pogo Pin: High-Quality Pogo Pin Manufacturer

If you’re looking for high-quality pogo pins for your next project, consider Promax Pogo Pin as your go-to partner! As a leading manufacturer in the pogo pin industry, Promax Pogo Pin offers an extensive range of pogo pin solutions to meet your specific needs.

Whether you require standard pins or custom designs, Promax Pogo Pin can provide all aspects related to pogo pins, as well as experienced guidance. Contact us today to learn more about how our pogo pins can improve your electronic devices and manufacturing processes.

What is a Pogo Pin? Pogo Pin Meaning FAQs

What is the lifespan of a pogo pin?

The lifespan of a pogo pin typically ranges from 10,000 to 1,000,000 cycles, depending on the application and usage conditions. High-quality pogo pins designed for durability may have longer lifespans, especially when used correctly.

Can pogo pins transfer data?

Yes, pogo pins can transfer data, as they can be configured with one signal-carrying pin surrounded by grounded pins to create a reliable connection inside the pin. This capability makes them great for applications like testing and programming electronic devices.

What is pogo pin configuration?

Pogo pin configuration refers to how the pins are arranged to optimize functionality, often arranged with one signal-carrying pin surrounded by grounded pins. These configurations may require a mold to ensure precise alignment, allowing effective contact inside the barrel and reliable performance for test pins.

Back to top: What is a Pogo Pin?

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days