Right Angle Pogo Pin Connector

Are you looking for the Right Angle Pogo Pin Connector of the precise size? are you greatly worried about how to find high-quality products, the shortest delivery time, the lowest cost, and optimal services? Dongguan Promax is a professional pogo pin connector ODM Factory & Manufacturer since 2014, we believe we can provide you with the best solutions & perfect products, looking forward to win-win cooperation!

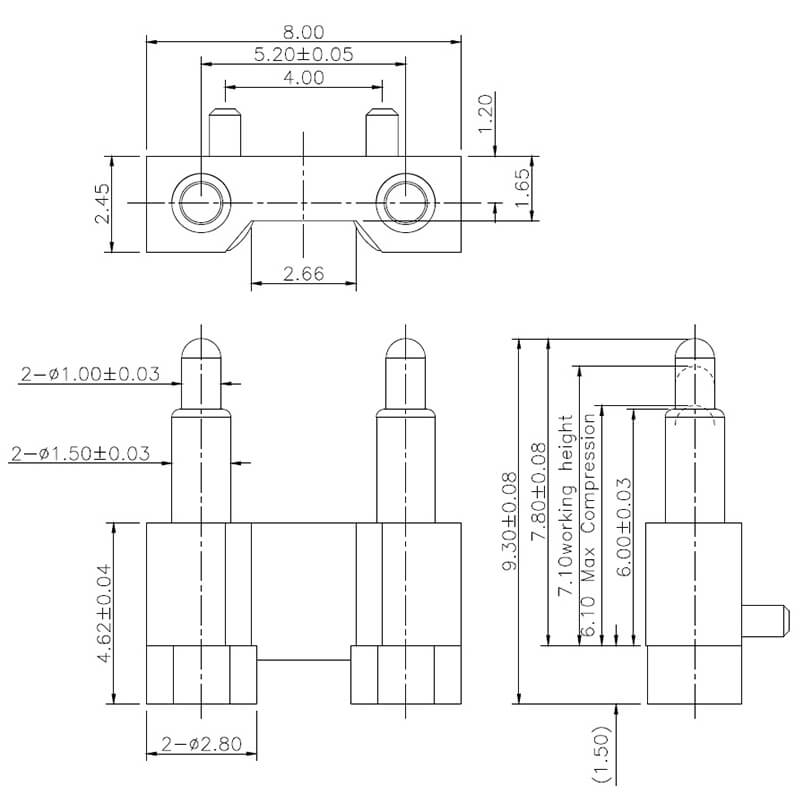

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

Right Angle, or others

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Use Case of Right Angle Pogo Pin Connector

The case was describing a right angle pogo pin connector used in a precise flash point tester from a famous industrial equipment company CYGIA Group, based on the customer’s requests, Read More ReadLess

So, in this case, we needed to provide the customer with a highly current product, and, based on the customer’s product structure, a right angle pogo pin connector was required. That was, it was a right angle pogo pin connector with a high current. Read More ReadLess

Studied customer’s requirement

Based on the requirements of the highly precise flashpoint tester and customer, we finalized the 2-pin structure of the right angle pogo pin connector, it was a 4 pieces structure with the ball, which can produce instantaneous high current. so, the connector was made of 2 plungers, 2 barrels, 2 balls, and 1 housing.

Read More

ReadLess

What is Its Structure?

The Right Angle pogo pin also consists of a plunger, barrel, and spring. But the barrel is special, it uses a minimal spatial structure while ensuring the connection of electronic components. Barrels are usually right angles. Read More ReadLess

What is The Electroplating Process?

Electroplating is an electrolysis process. The pogo pin material was surface treated to make it more resistant to corrosion and friction. The common surface treatments are nickel-plated gold and tin-plated copper. Read More ReadLess

The plating of a pogo pin is generally barrel electroplating. It is a kind of electroplating process that which a certain number of pogo pins are placed in a special drum, and the pogo pin surface is attached to various platings in a simple and conducive way under the rolling state.

Advantages of barrel electroplating: it can save small parts mount time. Many small parts must be wrapped with wire because there are no holes to be mounted. These methods are not only inefficient but also difficult to guarantee the electroplating quality. Rotating plating improves electroplating production efficiency and reduces labor costs.

Disadvantages of barrel electroplating: Pogo pins in the drum will collide with each other to produce adverse effects. The space between pogo pins is too small to cause discontinuous electroplating, which is prone to uneven film thickness.

Steps of Electroplating

Firstly, the degreasing time of the pogo pin is generally 2 ~ 5 seconds, so it needs multi-stage degreasing under high currents.

Secondly, deoxidation cleaning will be carried out after degreasing. Smooth its surface to prevent affecting the thickness of the plating layer.

Finally, the plating time was controlled to control the thickness of the plating layer. The thickness of the plating determines the conductivity and corrosion resistance of the pogo pin.

Some Common Applications:

- Cellular phones

- Laptops

- Tablets

- Digital cameras

- Camcorders

- Printers

- Scanners

- Automotive electronics

Industrial applications:

Pogo Pins are often used in industrial applications where a secure connection is needed. They are commonly used in assembly line testing, product inspection, and quality control. Pogo Pins are also used in a variety of automotive applications, such as engine control modules and infotainment systems.

Medical applications:

Pogo Pins are also used in a variety of medical applications. They are commonly used in blood pressure monitors, glucose meters, and heart rate monitors. Pogo Pins are also used in many implantable devices, such as pacemakers and defibrillators.

Why Choose Dongguan Promax?

Dongguan Promax has solved the problem of multiple Right angle pogo connectors for customers. From design drawings to sending samples, customers are very satisfied. We are also very happy to solve customer problems and apply our specialty to practical problems.