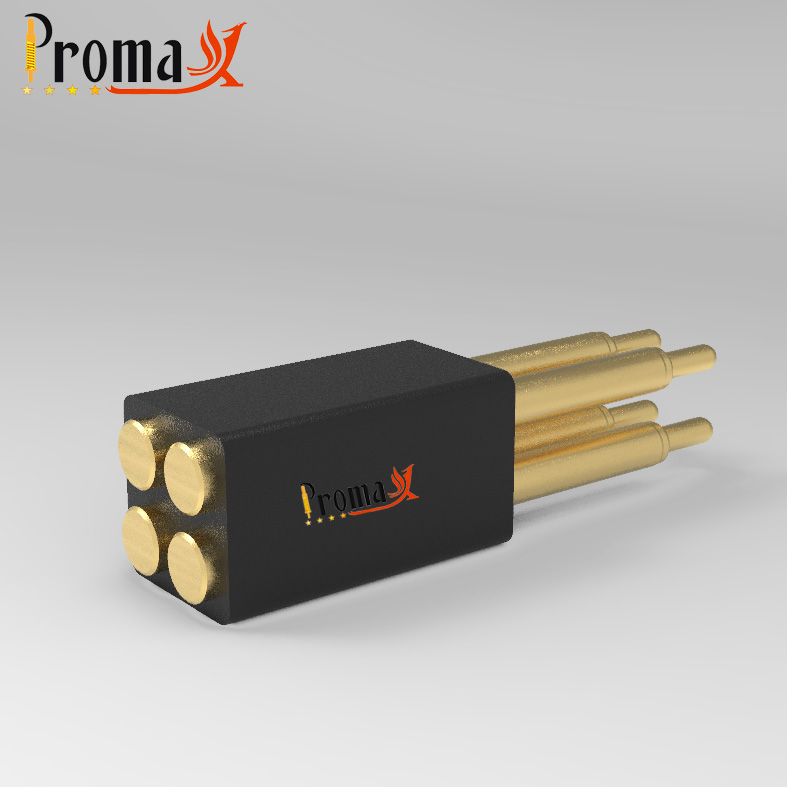

In a world where customization reigns supreme, the demands of customers continue to evolve at an unprecedented pace. As the production process of magnetic cable connectors unfolds, the need to meet personalized requirements has become increasingly prevalent.

From embedding logos and insignias to achieving specific surface finishes, the quest for enhancing the aesthetic appeal and functionality of these connectors has gained paramount importance. Enter the realm of plastic surface treatment technology—a fascinating frontier that holds the key to transforming ordinary connectors into extraordinary ones.

So, without further ado, let us embark on this enlightening voyage into the realm of plastic surface treatment, where innovation, customization, and the pursuit of excellence converge to create magnetic cable connectors that go beyond ordinary boundaries.

What’s Plastic Surface Treatment Process?

The plastic surface treatment process refers to a series of techniques aimed at modifying and enhancing the surface properties of plastic materials. It involves the application of various treatments and coatings to alter the appearance, texture, adhesion, and durability of the plastic surface.

These treatments can include processes like cleaning, polishing, etching, engraving, painting, printing, or applying protective coatings. The purpose of plastic surface treatment is to improve the aesthetics, functionality, and performance of plastic components, ensuring they meet specific requirements or customer preferences. By utilizing these techniques, manufacturers can achieve desired surface finishes, incorporate branding elements, enhance resistance to wear and corrosion, and facilitate better adhesion for subsequent processes like bonding or printing.

What are the Benefits of Plastic Surface Treatment?

The plastic surface treatment process offers numerous benefits for manufacturers and end-users alike. Here are some key advantages:

-

Improved Aesthetics:

Plastic surface treatments allow for customization and enhancement of the appearance of plastic components. Techniques such as coatings, printing, and laser etching enable the application of logos, designs, textures, and patterns, resulting in visually appealing products that align with branding or individual preferences.

-

Enhanced Durability:

Surface treatments like coatings or protective films can significantly improve the durability and resistance of plastic materials. They provide a barrier against scratches, abrasion, UV radiation, moisture, and chemicals, thereby extending the lifespan of the components and maintaining their original appearance.

-

Increased Functionality:

Plastic surface treatments can add functional properties to the material. For instance, chemical etching or surface roughening can improve the adhesion of coatings, adhesives, or printing inks, ensuring better bond strength and longevity of applied materials.

-

Branding and Identification:

Surface treatment technologies enable the incorporation of logos, serial numbers, or other identification markings onto plastic components. This helps with brand recognition, product authentication, and traceability throughout the supply chain.

-

Improved Cleanliness and Hygiene:

Certain surface treatments, such as antimicrobial coatings, can be applied to plastic materials. These coatings inhibit the growth of bacteria, fungi, or other microorganisms, making the components more hygienic and suitable for applications in healthcare, food processing, or sterile environments.

-

Compliance with Regulatory Requirements:

Plastic surface treatments can assist in meeting specific industry or regulatory standards. For example, coatings can provide fire resistance, chemical resistance, or electrical insulation properties, ensuring compliance with safety regulations and industry-specific requirements.

-

Facilitates Bonding and Assembly:

Surface treatments like plasma or flame treatment increase the surface energy of plastic materials, improving their adhesion properties. This allows for better bonding with adhesives, paints, or other materials during the assembly process.

-

Environmentally Friendly Options:

Many plastic surface treatment techniques offer environmentally friendly alternatives to traditional methods. Water-based coatings, eco-friendly cleaning solutions, or low VOC (volatile organic compound) treatments reduce the environmental impact of the process.

By leveraging the benefits of plastic surface treatment processes, manufacturers can enhance the functionality, aesthetics, and performance of plastic components, meeting the evolving demands of customers and industry requirements while ensuring durability and maintaining brand integrity.

Different plastic surface treatment technologies

Plastic surface treatment technologies encompass a wide range of techniques, each serving a specific purpose and offering unique benefits. Let’s explore several of these technologies:

-

Surface Cleaning and Pre-treatment:

Before any surface treatment can be applied, it is essential to thoroughly clean and prepare the plastic surface. This process involves removing contaminants, oils, and residues to ensure proper adhesion and the effectiveness of subsequent treatments.

-

Surface Coating:

Surface coating is a common plastic treatment method that involves applying a thin layer of material onto the plastic surface. Various coating options exist, such as paint, lacquer, or powder coating. Coatings provide aesthetic enhancements, improve durability, and protect against environmental factors like UV radiation and corrosion.

-

Printing and Decoration:

Printing and decoration techniques allow for the application of custom designs, logos, or patterns onto plastic surfaces. Methods such as screen printing, pad printing, or digital printing enable precise and high-quality graphics, ensuring brand recognition and personalization.

-

Laser Etching and Engraving:

Laser technology has revolutionized plastic surface treatment by offering precise and intricate etching or engraving capabilities. This technique allows for the creation of permanent markings, serial numbers, or decorative patterns without compromising the integrity of the plastic surface.

-

Plasma Treatment:

Plasma treatment is a process where the plastic surface is exposed to a low-temperature plasma gas. This treatment alters the surface chemistry, increasing surface energy and improving the adhesion of subsequent coatings, adhesives, or printing inks.

-

Flame Treatment:

Flame treatment involves passing a controlled flame over the plastic surface to modify its molecular structure. This process creates micro-roughness on the surface, improving adhesion for coatings, paints, or adhesives.

-

Chemical Etching:

Chemical etching is a method that utilizes chemical solutions to selectively remove or alter the plastic surface. This technique allows for controlled texture creation, surface roughening, or the removal of specific layers to achieve desired functionalities or aesthetic effects.

-

Surface Roughening:

Surface roughening techniques, such as sandblasting or abrasive blasting, create a textured surface on the plastic material. This process enhances adhesion, provides a matte finish, or prepares the surface for subsequent treatments like painting or coating.

-

Electroplating Plastic

Electroplating plastic is a surface treatment technique that involves depositing a thin metal layer onto the plastic surface using an electrochemical process.

This technology enhances the appearance, durability, and conductivity of plastic components. Electroplating can provide a variety of finishes, such as chrome, gold, or nickel, offering a high-quality metallic appearance. It also improves scratch resistance and provides shielding against electromagnetic interference. This process is commonly used in automotive, electronics, and decorative industries to create visually appealing and functional plastic parts with a metallic finish.

-

NCVM

NCVM (Non-conductive vacuum metallization) is a plastic surface treatment technology that involves depositing a thin metal layer onto non-conductive plastic surfaces using a vacuum deposition process. This technique allows for the creation of metallic finishes on plastic components, offering a reflective and visually appealing appearance.

NCVM coatings provide excellent adhesion, scratch resistance, and durability.

They are widely used in industries such as consumer electronics, automotive, and household appliances to achieve a premium metallic look on plastic parts, such as casings, buttons, or trims, enhancing product aesthetics and perceived value.

Each of these plastic surface treatment technologies offers manufacturers the flexibility to meet diverse requirements, enhance visual appeal, improve functionality, and ensure the longevity of plastic components in a wide range of industries. The choice of technique depends on the specific goals, desired results, and characteristics of the plastic material being treated.

Conclusion

In a competitive market where customization and quality are paramount, plastic surface treatment technologies empower the Pogo pin connector industry to deliver superior products that meet customer demands, exceed expectations, and strengthen brand reputation.

With the continuous advancements in surface treatment techniques, the industry can continue to innovate and unlock new possibilities for Pogo pin connectors, driving growth and success in the ever-evolving technological landscape.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days