LCD connectors are a common cause of problems with LCD screens. These connectors get dirty, and the dirt can cause problems with the screen. This is where this article can help you. It will provide you with a list of the most common issues, like how to clean CLD connectors, and how to clean ribbon cable connectors.

What is an LCD Connector?

LCD connectors are used to connect a monitor to a computer. You can typically find them on the back of the monitor, often black or dark grey. They are small and may be difficult to see. LCD connectors can get dirty and may cause issues with the monitor. Manufacturers usually coated them in a thin layer of dust and debris.

Types of LCD Connections

LCDs are great for displaying information, but sometimes it can be a hassle trying to figure out how to connect them. This blog will explore the different types of LCD connectors that you may encounter in a home theater system.

-

Zebra Strips or Elastomeric Connectors

Elastomeric connectors are a common connection type for LCDs with surface mount connections. It’s easy to install them because they are flexible. They are also soft and can conform to most surfaces. You can typically use them for flat panels but can also use them for curved-screen models.

People typically use these connectors for applications where the panel needs to be mounted on a surface, such as a wall. Elastomeric connectors, also known as zebra stripes, are mostly best for laptops, home theater projectors, and other LCDs where the LCD is mounted on the front or back of the device.

Laptop manufacturers are using these connectors because they are less likely to break. When sealing the connector, an elastomeric connector is typically waterproof by the device’s housing. To make the connector waterproof, you will need to seal the area where the connector is connected to the LCD. You can use epoxy putty or silicone sealant to do this.

-

FPC/FFC Connectors

Flexible Printed Circuit (FPC) and Flexible Flat Circuit (FFC) refer to a cable with a circuit board or substrate in which you embed the individual wires in a flexible printed circuit. A flexible Printed Circuit is a type of flexible cable that is used to interface with a display. It is a very flexible, thin cable you can route through a PCB in minimal space.

FPC cables are also useful for PCBs that have a limited amount of space for routing signals. You can easily attach FPC with your LCD. You can attach one end of the cable to the back of the LCD panel, and the other to the board containing the electronics that drive the display. The FPC cable is very flexible, allowing it to bend around the LCD panel easily.

-

Through Holes

A Through Hole connection is the most common type of connection on the back of an LCD. It created the connection with a small hole in the display PCB. This connection type is most common for LCDs with an external PCB controller circuit mounted on display.

-

Metal Pins and Ribbon Cables

There are two main connection types for LCDs: metal pins and ribbon cables. Metal pins are much more popular than ribbon cables. To connect a metal pin LCD to a computer, you must connect the display controller to the computer and the COM and segment lines to the computer. You can mostly use ribbon cables for character displays because they transmit signals faster than metal pins.

-

Heat Seal

Heat Seal connections are one of the most widely used connector types. You can use them on displays that do not have a cable connector. They use a flexible cable connector that is heated and sealed to the displays’ interface ports. The connector then adheres to the display using conductive glue, and you can seal it using heat. This connection type is reliable, durable, and simple to use.

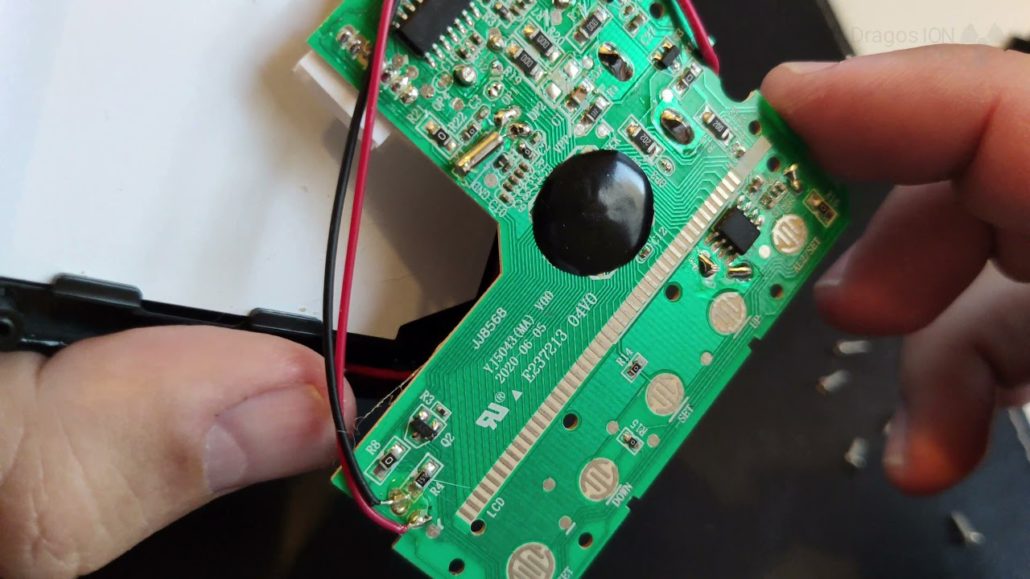

How to clean elastomeric connectors for LCD

Companies usually make elastomeric connector strips from silicone, making them flexible and durable. Unfortunately, these connectors are also prone to dust and other particles, which can cause problems with your LCD monitor.

Cleaning method:

There are two ways to clean the LCD connectors:

- Use a toothbrush to scrub them gently. Keep the toothbrush wet with a small amount of water and gently scrub the connectors.

- Use a microfiber towel and a little bit of rubbing alcohol. Do not use a lot of rubbing alcohol, just a little.

How to repair an LCD zebra connector

The LCD zebra connector is a small piece of plastic that sits on your device’s screen. When the screen gets cracked or broken, you can easily replace it. You can fix this problem at home or in the field. Repair and LCD Zebra Strip Connector in one step: Take out the LCD connector from the device and fix the problem with a soldering iron.

Can you fix an LCD screen without replacing it?

If your LCD screen is severely not working or cracked, then the only option is to replace it because you cannot repair LCD screens at home.

How to prevent your LCD connectors from getting dirty again

LCD connectors are hard to clean because they are not accessible. However, you can do a few things to minimize the risk of getting into the connector. If they are, clean the connectors and the surrounding area. Next, you should periodically clean the connectors.

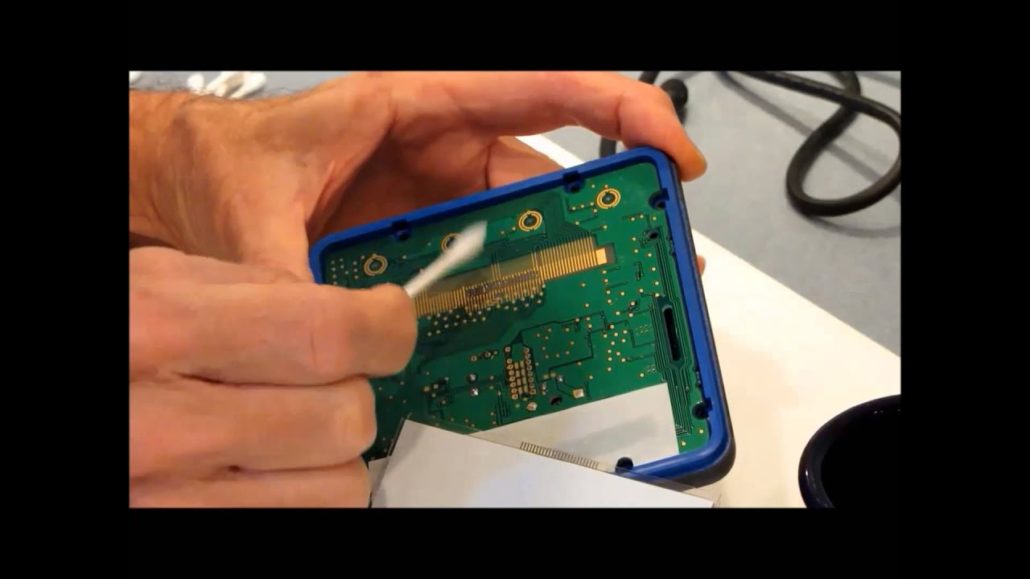

How to clean ribbon cable connectors

When working on a project that uses a ribbon cable, you must clean the ribbon connector before connecting the ribbon cable to the circuit board. Do this to prevent the connection from shorting out. To clean the ribbon connector, there are a few things that are required:

- Isopropyl Alcohol,

- A Q-tip

- Toothbrush

Method:

- Start by using the Q-tip to clean the contacts of the ribbon cable connector.

- Use a toothbrush to clean the inside of the connector.

- Finally, use the isopropyl alcohol to clean the outside of the connector.

Why is the LCD screen not working?

If you’re wondering why your LCD screen is not working, you might deal with a problem related to the screen’s circuitry. If something is wrong with the screen’s circuitry, it could be a problem with the power supply, the sound system, or the video input. Test all these distinct possibilities before you assume the screen is broken. A faulty power supply can cause a short circuit between adjacent data lines. If the power supply is not working, the faulty power supply can cause the data lines to be shorted together, leading to a faulty display. So make sure you examine for short circuits between adjacent tracks going to the LCD.

What products should never be used to clean an LCD screen?

Any cleaner that includes methyl chloride, ethyl alcohol, acid, and ammonia must not be used for cleaning screen surfaces. Also, avoid any solvent cleaner that harms the delicate screen of the LCD.

FAQs:

How do you clean ribbon wire?

To clean the ribbon wire, use denatured alcohol and wet a paper towel.

How do you clean the inside of an LCD screen?

There are three steps to clean the inside of an LCD screen:

- Disconnect the power cable from your LCD. For Laptops, remove the battery.

- Wipe the dust with a dry soft towel or use a lint-free cloth.

- Gently clean the screen with the help of a wet microfiber cloth.

How to clean the LCD connector with vinegar?

Always use a paltry amount of vinegar, and mix well in water before cleaning the LCD connector.

Does the sun damage LCD screens?

Ultraviolet rays that come from sunlight can physically damage the LCD screen.

Conclusion

LCD screens are a staple of modern technology and a must-have for anyone constantly on their computer. Most of us take our screens for granted and don’t realize how dirty they can get. With a little effort, you can learn how to clean LCD connectors and keep your screens looking as good as new.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days