How to de-pin a connector?

We often see wiring harnesses in new energy vehicles. The connector is the relay station of the wiring harness in the automobile circuit. The connection between wire harness and wire harness, wire harness, and electrical parts is generally connected by connectors. The automotive wire harness connector is an important part of connecting various electrical and electronic equipment of automobiles.

To prevent the connectors from coming off while the car is moving, all connectors are equipped with latching devices. To disassemble the connector, first, release the latch and then pull the connector apart. Do not pull the harness without releasing the latch, as this will damage the latch or the connecting harness.

What parts do automobile connectors have?

Automobile connectors are usually composed of contact pins, insulating housings, shells, and accessories. The contact pin is the core part of the connector to complete the electrical connection function. Generally speaking, the connector contact refers to the male connector and female connector contact, through the stable connection of male and female contact to complete the signal transmission.

Insulators, also known as base or mounting plates, are used to arrange pins in the desired position and spacing and to ensure insulation between pins and between pins and shells.

| Component | Description |

|---|---|

| Contact Pins | Core parts of the connector that complete the electrical connection function |

| Insulating Housings | Base or mounting plates used to arrange pins in the desired position and ensure insulation |

| Shells | Outer covers of the connector that provide mechanical protection and alignment |

| Accessories | Additional components or features that enhance the functionality or performance of the connector |

Good insulation resistance, voltage resistance, and machinability are the basic requirements for insulating materials. The housing is the outer cover of the connector, which provides mechanical protection for the built-in insulating mounting plate and pins, and provides the proper alignment of plug and socket inserts to secure the connector to the device.

With the global ratio of new energy vehicles and the continued penetration of automotive intelligence, it is expected to continue to drive the growth of the market size of automotive connectors. However, in the process of using automotive connectors, pins often need to be removed for inspection or replacement. That is why we need to know how to de-pin from the connector.

How to use a special tool to de-pin from the connector?

With the growing development of new energy vehicles, various automobile manufacturers have launched their own new energy vehicle products, including pure electric vehicles and hybrid vehicles. The wire harness is an important part of the automobile power transmission system, and the connector is an important connecting part of the wire harness.

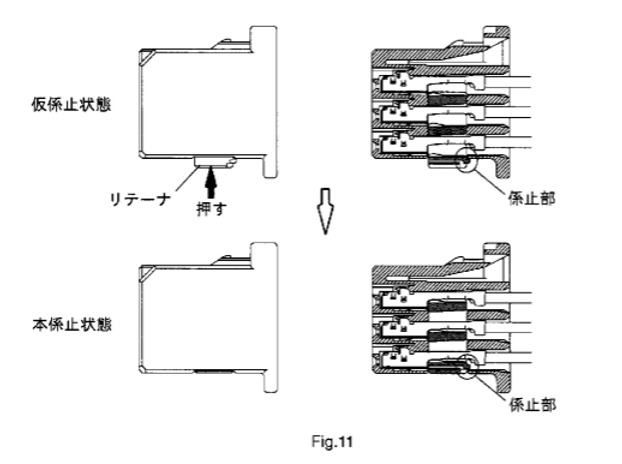

The pins of strong electric connectors have locking structures, which are locked by opening the locking plate. In the locked state, they cannot be pushed out in the direction of insertion.

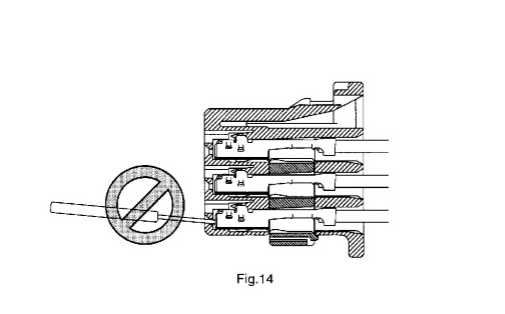

Therefore, disassembly or repair without special tools is very time-consuming and laborious, or can only destroy the plug pins. Don’t worry, we have special disassembly tools. Thanks to this special disassembly tool, we can easily push the pins out of the connector.

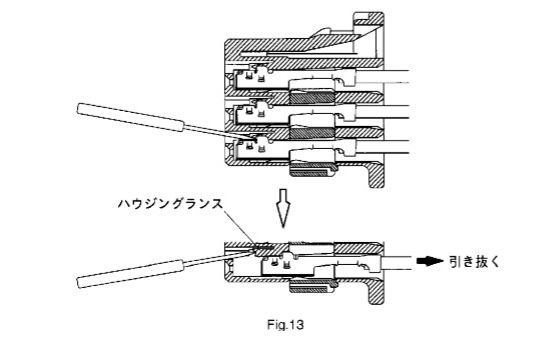

The special tools on the right side of the handle are fixed with an internal empty sleeve, the sleeve is inserted into the connector socket head and set on the outside of the pin, forward extrusion lock until the lock pieces together, the pin into the sleeve inside whole again, finally drive the pin back together, the fixed clamping groove of the pin is released, so as to achieve the aim of de-pin from the connector.

It is important to note that it is difficult to insert the sleeve into the deep position of the retaining clamp groove of the connector socket while fully inserting the pin into the deep position of the sleeve. When the outer diameter of the pin is close to the inner diameter of the fixed clamping groove of the connector socket, the sleeve cannot be inserted into the fixed clamping groove at all.

Even if it can be inserted, it is more difficult to pull out in the opposite direction, so it cannot be quickly and conveniently pushed out of the pin. The front end of the auto connector unlocking sleeve protrudes from the front end of the thimble when it is in the assembly state, and the locking sheet of the connector can be compressed back to the contraction position to unlock.

The sleeve is resistant and, through the push rod with a pressure spring back, the thimble can promote launch socket connector pins, and recover the pin, after completion of the disassembly of the pin under pressure spring of rebound is automatically returned from the socket, the entire launch process using action is done once, very accurate rapid, efficient, convenient, save time and effort, And the pin is in good condition to be used again. You can change the unlocking sleeve in different sizes according to different types of connector pins.

The importance of connectors for new energy vehicles

The automotive wiring harness connector is a key part of the field of new energy vehicles, which directly determines the ability of signal and power transmission. In recent years, the new energy automobile industry is developing rapidly, and the gradual improvement of the automobile parts field driven by it also affects the development of automobile connectors for reliability and refinement.

The automotive connector pin is an important part of signal transmission, its reliability is very important and needs strict control. By summarizing the problems existing in the use of the connector pin, we found that the pin is easy to be damaged in the process of installation or disassembly, so it is necessary to understand the correct way to de-pin from the connector.

We are reliable connector pin manufacturers

If you are looking for a reliable connector pin manufacturer, Dongguan Promax Electronics Technology Co., Ltd will not let you down. We have a professional design team, and through innovation, and advanced technologies, our connectors are able to satisfy those growing needs and are widely applied to various applications in the field, such as higher durability, waterproofing, space efficiency, and miniaturization.

We implement total quality control from raw material to finished product. we meet these goals by continually improving the effectiveness of our Quality Management System, to ensure that the quality of products satisfies customer requirements.