In the dynamic world of healthcare, technology continues to transform patient care, and two key players are leading the charge: medical devices and electrical connectors.

These dynamic duos can drive healthcare to new heights, empowering medical professionals to deliver precise, efficient, and groundbreaking treatments.

Wanna dive headfirst into the fascinating world of medical devices and electrical connectors? This article will uncover their incredible impact on patient care and spill the beans on the latest breakthroughs.

Get ready to be amazed by how these cutting-edge technologies are transforming healthcare! These revolutionary treatments defy imagination with unprecedented precision and mind-blowing innovation.

We’ll explore the most recent advancements, delve into cutting-edge applications, and navigate the thrilling possibilities that emerge from the intersection of medical devices and electrical connectors.

So, let’s get into the fantastic possibilities that lie within this partnership, inspiring a new era of interconnected care.

Electrical Connectors In Medical Equipment

The Role of Electrical Connectors in Medical Equipment

Electrical connectors are vital for medical equipment, enabling reliable connections and seamless communication and power transmission.

Interconnection

Electrical connectors harmoniously interconnect components in medical equipment, facilitating signal, data, and power transfer. They link sensors to monitoring systems and integrate modules in surgical devices for efficient collaboration.

Signal Transmission

Electrical connectors ensure accurate and uninterrupted signal transmission in medical devices, preserving signal integrity for vital signs, imaging data, and diagnostics.

It minimizes the risk of data loss or distortion, allowing precise data reception, processing, and transmission.

Power Delivery

Electrical connectors ensure a stable power supply for the effective operation of medical devices.

They ease uninterrupted energy flow from the source to the device, supporting the performance of life-saving technologies.

Connectors serve as reliable pathways for power distribution, enabling the proper functioning of portable devices like insulin pumps and complex imaging systems.

Importance Of Reliable Electrical Connections In Medical Equipment

- Patient safety relies on reliable electrical connections in medical settings. They ensure accurate data transmission, prevent malfunctions, and minimize risks. Strong connections between devices empower informed decisions, improving patient outcomes.

- Accurate readings and interpretation depend on dependable connections, ensuring precise vital signs, imaging results, and diagnostic information. Trustworthy data enables healthcare professionals to make accurate diagnoses and treatment decisions.

- Uninterrupted power delivery and signal transmission are critical for accurate dosage in anesthesia machines and precise movements in surgical robots. Reliable connections ensure device performance and enhance healthcare delivery.

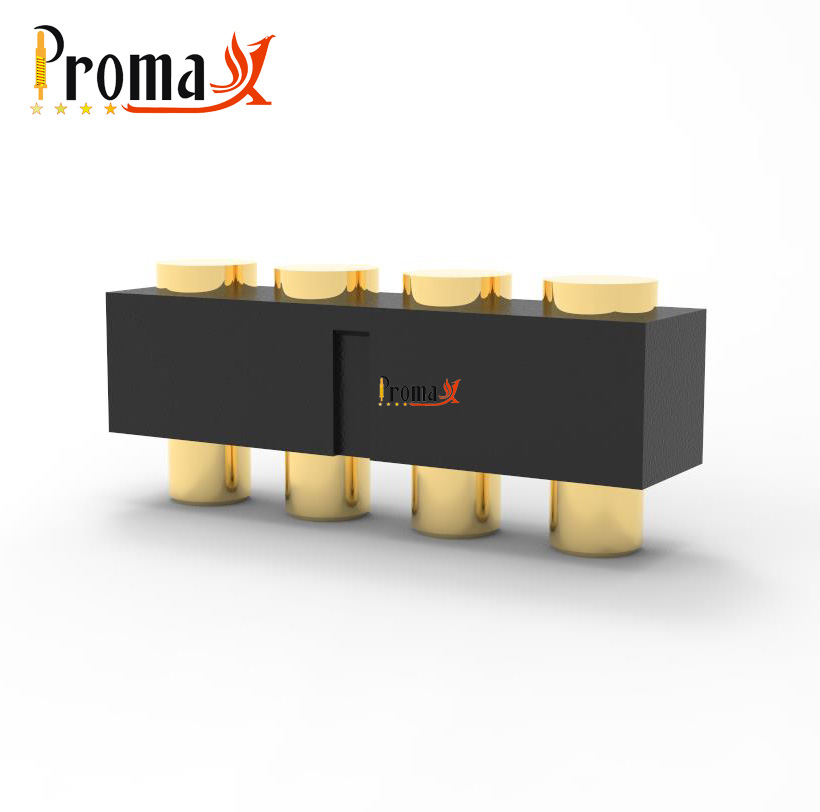

Common Types Of Electrical Connectors In Medical Devices

Medical devices use various electrical connectors, each with specific purposes. Here are three common types:

- Coaxial connectors transmit high-frequency signals in medical imaging devices, comprising a metal conductor, dielectric insulator, and metal shield. Panel mount connectors connect medical devices to power sources or other devices and are usually mounted on panels or chassis.

- Implantable device connectors are designed for connecting medical implants such as pacemakers and defibrillators to the body. They should be biocompatible and durable to withstand the harsh internal body environment.

- Fluid delivery system connectors connect medical devices like infusion pumps with IV pumps to deliver fluids to the body. They are designed to be leak-proof and withstand high fluid pressures.

Advanced Technologies In Medical Device Connectors

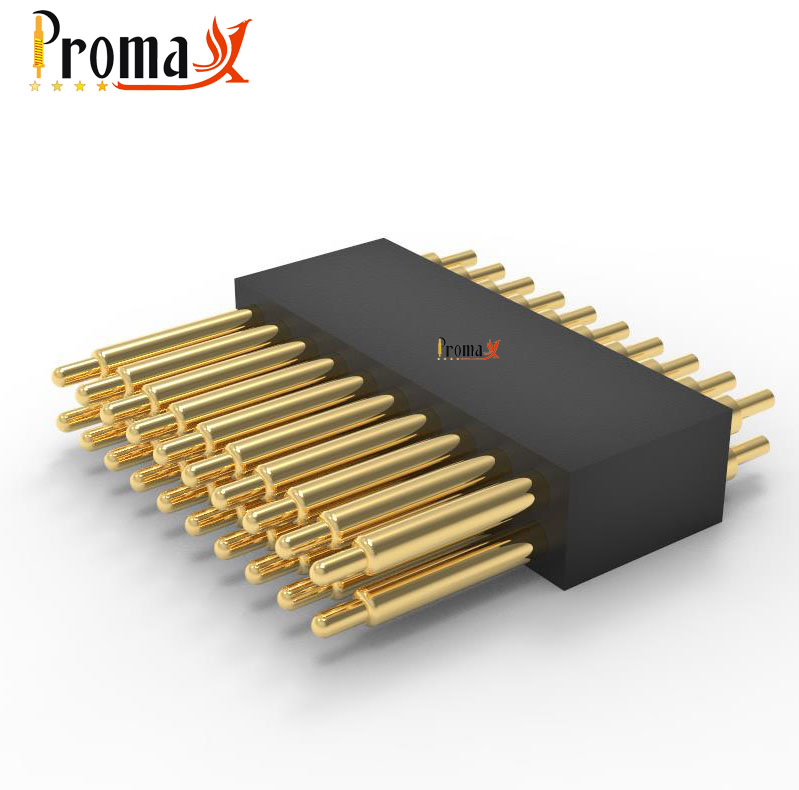

Miniaturization And High-Density Connectors

The need for compact medical devices has spurred the development of miniaturized connectors.

They offer portability and ease of use, particularly in wearables and implantable devices, while ensuring reliable electrical connections.Also, high-density connectors enable the integration of many electrical connections in a small footprint.

Thus, they support the design of multifunctional and complex medical devices.

Miniaturized and high-density connectors have transformed medical applications, enabling compact and lightweight devices for improved patient comfort, mobility, and advancements in remote patient monitoring and minimally invasive procedures.

Wireless And Bluetooth-Enabled Connectors

Wireless technology has revolutionized medical device connectors, eliminating physical cables. Bluetooth, Wi-Fi, and radio frequency (RF) are used to establish wireless communication, providing freedom of movement for patients and healthcare professionals.

Wireless connectors enable seamless data transmission between medical devices and external systems, revolutionizing remote monitoring, real-time data sharing, and mobile health solutions.

They also enhance infection control by reducing the need for physical connectors and cables that can harbor pathogens.

Smart Connectors And Data Integration

Smart connectors incorporate sensors, microprocessors, and memory modules, performing tasks like data acquisition, signal processing, and device identification. They adapt to different devices, optimizing communication and power delivery.

These connectors seamlessly integrate data among medical devices, improving workflows, patient care coordination, and decision-making. They enhance interoperability and data exchange, elevating efficiency and quality of care.

Smart connectors and data integration revolutionize EHRs, telemedicine, and connected healthcare. Real-time data collection, analysis, and remote monitoring enable personalized and proactive healthcare delivery.

Biocompatible Materials For Connectors

Biocompatible materials in medical device connectors minimize the risk of adverse reactions, allergies, and tissue damage.

They ensure compatibility with the patient’s body, being non-toxic, non-irritating, and suitable for the physiological environment. The materials like medical-grade plastics, stainless steel, titanium, and specialized coatings are used in medical device connectors.

They undergo rigorous testing for safety and compatibility with human tissues. Biocompatible connectors minimize patient discomfort and reduce the risk of adverse reactions in implantable devices, surgical instruments, and devices requiring prolonged skin contact.Biocompatible materials improve patient safety, comfort, and device performance.

They also enable the seamless integration of implantable and wearable medical devices with the human body.

Challenges And Future Trends In Medical Device Connector Technology

Interoperability And Standardization

Interoperability and standardization are critical challenges in medical device connector technology. Incompatible connectors and communication protocols hinder seamless data exchange and device compatibility.

Efforts by industry stakeholders, regulatory bodies, and standards organizations like IHE and Continua Health Alliance aim to establish common standards and protocols, promoting interoperability and care coordination. Standardization enhances the integration of diverse medical devices within healthcare systems, overcoming compatibility issues.

Cybersecurity Concerns

The increasing connectivity of medical devices poses cybersecurity risks that must be addressed to protect patient safety and privacy. Unauthorized access, data breaches, and compromised functionality are potential threats.

Manufacturers should integrate robust security measures into connector technology, including encryption, authentication, and secure data transfer protocols.

Regular updates and patches are essential. Healthcare organizations should establish cybersecurity policies, conduct risk assessments, and implement network security measures to safeguard connected devices and their connectors.

Connector Miniaturization And Integration

Miniaturization and integration are key trends in medical device connector technology. As devices become smaller, connectors should be able to maintain reliable connections in shrinking form factors.

Advancements in MEMS and nanotechnology enable miniature connectors with high signal density.Integrated connectors combine multiple functionalities, reducing the number of connectors needed, simplifying design, and improving system reliability.

They support the development of smaller and more efficient medical devices by incorporating power, data, and sensor connections in a compact form factor.

Wearable Medical Devices

Wearable medical devices are in high demand, providing continuous monitoring, remote patient management, and personalized healthcare. These devices, worn or integrated into clothing, need durable connectors that can handle movement, maintain reliable connections, and accommodate flexible circuitry.

Flexible and stretchable connectors provide an ideal solution for wearable medical devices. They effortlessly bend, twist, and adapt to the body’s movements while maintaining optimal electrical performance.

With the help of materials like conductive textiles, elastomers, and flexible PCBs, connectors can offer comfort, durability, and suitability for long-term wear.Wireless connectivity in wearables eliminates physical connectors, improving user comfort and reducing skin irritation.

Wireless charging removes the need for traditional power connectors.Wearable medical devices revolutionize healthcare through continuous monitoring and improved patient engagement.

Common Applications Of Electrical Connectors In Medical Devices

- In patient monitoring systems, electrical connectors help enable accurate data acquisition and continuous monitoring of vital signs. They establish connections between sensors, electrodes, and monitoring devices, ensuring reliable data transmission.

- Electrical connectors are integral to diagnostic imaging equipment like X-ray machines, CT scanners, MRI systems, and ultrasound machines. They enable transmitting imaging data, power, and control signals, promoting precise diagnosis and treatment planning based on detailed images.

- Implantable medical devices like pacemakers, neurostimulators, and defibrillators rely on electrical connectors for reliable connections with external programming devices and power sources. These connectors enable programming, battery charging, and data exchange between the implanted device and external components.

- Electrical connectors are vital in infusion pumps and drug delivery systems, ensuring the safe and efficient administration of medications, fluids, and nutrients to patients. They establish secure connections between the pump, infusion sets, and patient-specific delivery lines.

- In prosthetic devices, including bionic limbs and hearing aids, electrical connectors connect sensors, electrodes, and power sources. They enable precise control of the prosthetic limb and facilitate effective sound processing in hearing aids.

Conclusion

In medical devices, electrical connectors ensure reliable communication and power transmission. The advancements in connector technology have revolutionized the healthcare industry, leading to innovative devices and enhanced patient care.

These advancements have improved device performance and patient comfort from miniaturization to biocompatible materials. But, challenges such as interoperability, cybersecurity, and the need for standardization remain.

The future trends of connector technology include integration, wearables, and adherence to industry standards.

The continuous progress in electrical connector technology will undoubtedly shape the future of medical equipment, contributing to improved healthcare delivery and patient outcomes.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days