Looking to expand your knowledge of how SMT connectors play a crucial role in printed circuit boards (PCB)? You’ve come to the right place!

This article will delve into the different types of SMT connectors available, their benefits and drawbacks, and how they stack up against their through-hole counterparts. We’ll also explore the latest trends and innovations in SMT connector technology and pro tips for selecting the proper connector for your PCB design.

Whether you’re a seasoned PCB designer or just starting, this article has something for everyone. So let’s explore the ins and outs of these tiny yet essential components.

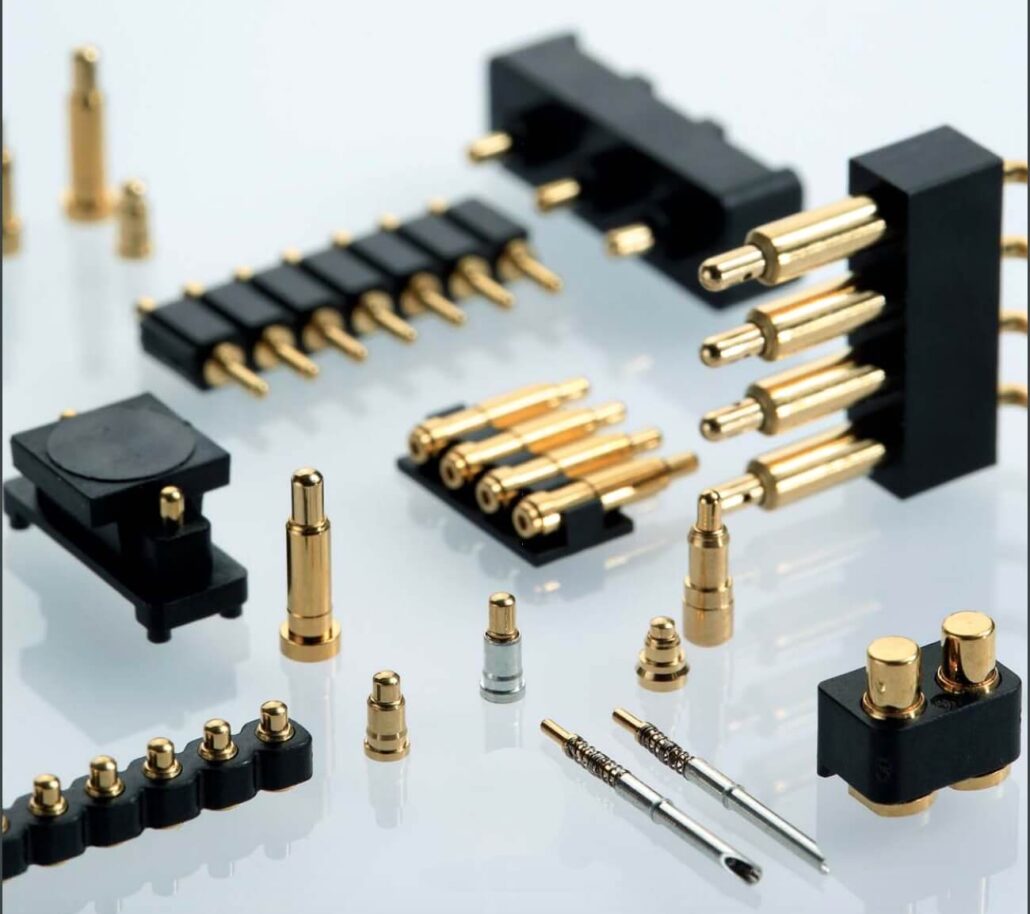

SMT-Connectors in PCB: What They Are?

SMT (Surface Mount Technology) connectors are a type of electronic component used in PCB (Printed Circuit Board) design and manufacturing. Their primary function is to link the PCB and other electronic components or devices securely and reliably. Unlike through-hole connectors that require holes to be drilled through the PCB, SMT connectors are mounted directly on the board surface, making them more compact and easier to assemble. They come in various shapes, sizes, and pitch configurations and have a wide range of applications, including consumer electronics, automotive, aerospace, telecommunications, and more.

Types of SMT Connectors

When it comes to SMT connectors, there are various types available to cater to different electronic designs. Here are the most common types of SMT connectors and their features and benefits:

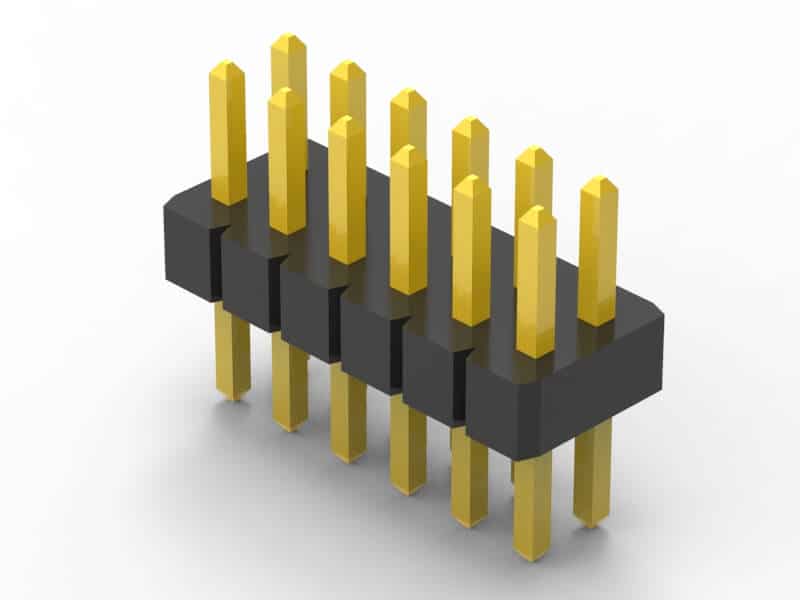

The header connectors, plated with gold, nickel, or tin, come with contacts for PCB surface soldering. They’re used for signal and power connections in surface mount applications. Their pitch sizes range from 0.5mm to 2.54mm, with pin counts from 1 to over 100.

Header connectors find uses in various applications, such as industrial equipment, consumer electronics, telecommunications, and other electronic devices.

-

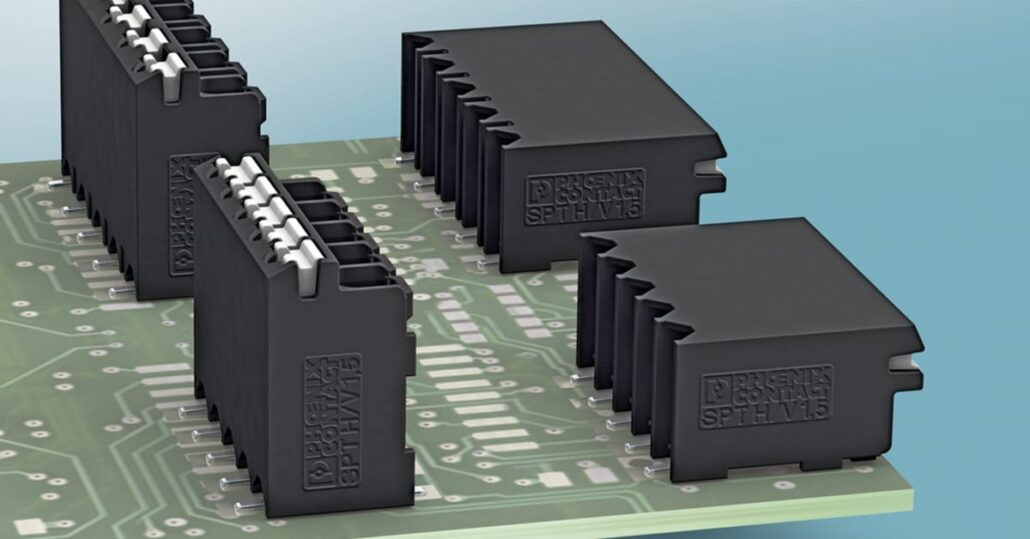

Terminal Block Connectors

Terminal block connectors link wires to a PCB, with options for surface-mount or through-hole connections. They vary in pitch size, from 2.54mm to 15.24mm, and pin count, from 2 to over 20.

Terminal blocks are made of nylon or ceramic materials with metal contacts for durability and reliable conductivity. These connectors are often found in industrial equipment, power supplies, motor control systems, and other electronics that require high-current connections.

-

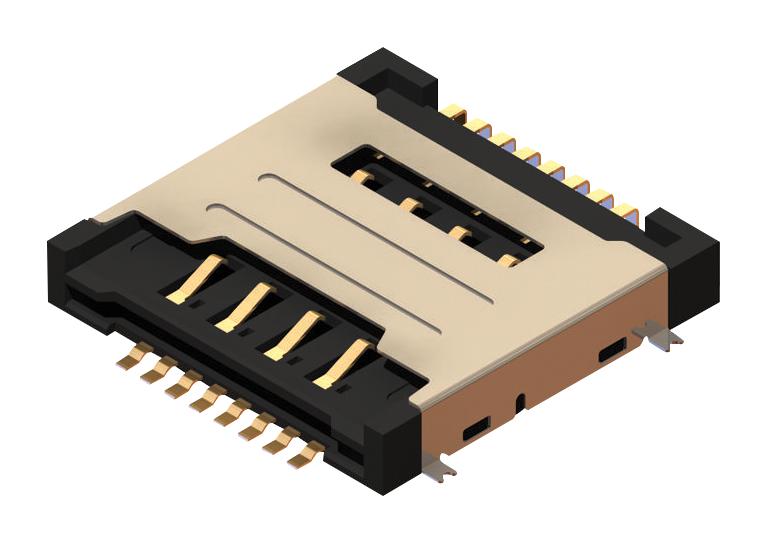

Battery Connectors

Metallic battery connectors, made from brass or copper-like metal, link batteries with PCBs. They come in diverse shapes and sizes, mountable either through-hole or surface-mount. Robust and long-lasting, they guarantee excellent conductivity for high-current operations.

Battery connectors ensure dependable and safe connections between batteries and PCBs. They suit different battery types and applications, including mobile devices (e.g. smartphones, tablets, and laptops) and industrial gear.

-

RF Connectors

RF connectors, typically composed of brass or stainless steel, link RF components to a PCB. They come in various types, such as SMA, SMB, and BNC, with options for threaded or snap-on installation.

RF connectors offer a high-frequency signal path, low signal loss, and impedance matching, making them ideal for wireless communications, radar systems, and similar applications.

DIN connectors, comprising metal materials like brass or zinc, facilitate audio and video connections, with types like DIN 41612 and mini-DIN.

These connectors provide a uniform interface for audio and video applications and find widespread use in audio and video equipment, including mixers and home theater systems.

-

D-sub Connectors

D-sub connectors link serial and parallel data connections, with options like DB9 and DB25 and varied setups to suit different applications. Typically made from metals such as steel or zinc, they offer a standardized interface for data connections.

They are widely used in computer equipment, including modems, printers, and serial/parallel ports.

-

USB Connectors

USB connectors provide a standard interface to link USB devices to a PCB. They come in various types, such as USB Type-A, Type-B, and Type-C.

For reliable conductivity, they are often crafted from plastic or metal with metal contacts. These connectors are widely used in everyday applications, including mobile phones and computer accessories like keyboards, mice, printers, and external hard drives.

-

HDMI Connectors

HDMI connectors facilitate high-definition multimedia connections and are available in various types like HDMI Type-A, Type-B, and Type-C. HDMI connectors are engineered with robust materials, such as plastic or metal, and equipped with metal contacts to ensure a stable and durable connection.

HDMI connectors provide a standardized interface for audio and video devices, ensuring ease of use and broad compatibility. They deliver high-quality signals with minimal loss. These connectors are widely used in home theater systems, gaming consoles, and other audio and video equipment that demand high-definition multimedia connections.

SMT Connectors Vs. Through-hole Connectors

Surface mount technology (SMT) connectors offer many advantages over through-hole connectors.

-

Ease of Assembly

SMT connectors are much easier to assemble than through-hole connectors since they do not require any drilling of holes. It means that PCBs can be assembled more quickly and with greater accuracy, reducing the risk of errors during production.

-

Higher Density

By mounting directly onto the PCB surface, SMT connectors offer a space-saving solution compared to their through-hole counterparts. This means that designers can fit more components onto a single PCB, which is particularly useful for smaller devices where every millimeter counts.

-

Cost

SMT connectors are generally less expensive than through-hole connectors since they require less material and are easier to assemble. It can result in lower production costs for manufacturers, which can be passed on to customers.

-

Better Electrical Performance

SMT connectors have a shorter signal path than through-hole connectors, so they can offer better electrical performance. They also have lower parasitic capacitance and inductance, reducing signal noise and distortion.

SMT Connector Technology Trends and Innovations

Some trends and innovations in SMT connector technology are worth noting as technology advances.

-

Increased Data Transfer Rates

With the proliferation of high-speed data transfer applications, there is a growing need for SMT connectors to handle higher data transfer rates. Manufacturers are now producing connectors to support data transfer rates of up to 56 Gbps, allowing faster and more reliable data transmission.

-

Improved Thermal Performance

High-power applications can generate a significant amount of heat, affecting the performance and lifespan of SMT connectors. Manufacturers are developing connectors with improved thermal performance, such as connectors with advanced heat dissipation technology and higher temperature ratings, to address this issue.

-

Increased Design Flexibility

As devices become smaller and more complex, there is a growing need for SMT connectors to offer greater design flexibility. Manufacturers are now producing connectors with customizable configurations and modular designs, allowing designers to create connectors that meet their specific requirements.

-

Miniaturization

Miniaturization is a trend that has been driving SMT connector technology for many years. The demand for tiny and lightweight connectors is increasing as electronic devices become smaller and more compact. Manufacturers are now producing minuscule connectors with pitches as low as 0.35mm.

-

Improved Reliability

SMT connectors are critical components in many electronic devices, and reliability is of utmost importance. Manufacturers are now producing connectors with improved reliability, such as connectors with higher durability and resistance to environmental factors like moisture and dust.

-

Increased Durability

Manufacturers are developing highly durable connectors, offering resistance to physical damage to meet the demands of rugged environments. These connectors are designed to withstand extreme temperatures, shock, and vibration.

-

Application-Specific Connectors

With the diversity of applications requiring SMT connectors, manufacturers are making connectors tailored to specific applications. These connectors may have unique form factors, materials, or features to make them ideal for a particular application.

Selecting the Right SMT Connector for Your PCB Design

Selecting the suitable SMT connector for your PCB design is critical in ensuring your electronic device performs as intended. Here are some practical tips to help you choose the best SMT connector for your specific PCB design needs:

-

Consider the Number of Pins

The number of pins required for your SMT connector will depend on the specific application. Choose a connector with enough pins to accommodate all of the necessary connections. However, avoid choosing a connector with more contacts than you need, as this can increase the cost and complexity of your PCB design.

-

Determine the Pitch

Choosing the right pitch for an SMT connector is crucial in determining the size and layout of your PCB design. The pitch refers to the distance between adjacent pins and can greatly impact the density and functionality of your board. Select an appropriate pitch that matches the size and requirements of your project to ensure optimal performance and reliability.

-

Consider the Temperature Range

The connector’s ability to withstand temperature changes and maintain functionality is critical for reliable device operation. Always choose a connector with an operating temperature range that suits your device’s needs. Opt for a connector offering a higher temperature range or add thermal management features if the device will face extreme temperatures.

-

Consider the Required Current Rating

The current rating of an SMT connector refers to the maximum amount of current that can pass through the connector without causing damage. Choose a connector with an appropriate current rating for the specific requirements of your application.

-

Evaluate the Reliability of the Connector

SMT connectors are critical components in electronic devices, and their reliability is vital to ensure proper functioning. Considering the reliability of the connector, choose a connector with a proven track record of performance and durability.

Best Practices for Working with SMT Connectors

Here are some best practices for working with SMT connectors:

-

Soldering Techniques

SMT connectors require precise soldering techniques to ensure proper connection to the PCB. Use the appropriate soldering technique, such as reflow or wave soldering, and follow the manufacturer’s recommended soldering profile. To ensure reliable and consistent solder joints, it is also crucial to use high-quality soldering materials and equipment.

-

Inspection and Testing

Inspection and testing are critical steps in the assembly process to ensure that the SMT connectors are properly aligned, soldered, and functioning as intended. Use a high-quality inspection microscope to check the alignment and quality of the solder joints, and use a multimeter or other testing equipment to verify the functionality of the connectors.

-

Proper Handling and Storage

SMT connectors are sensitive components and can be easily damaged if not handled and stored appropriately. Always handle SMT connectors with clean, dry hands or gloves to avoid contamination or damage. Store SMT connectors in a clean, dry environment with controlled temperature and humidity to prevent moisture or dust buildup, which can affect the performance and reliability of the connectors.

-

ESD Protection

Electrostatic discharge (ESD) can cause significant damage to SMT connectors and other electronic components. Always use proper ESD protection equipment, such as antistatic mats, wrist straps, and grounded workstations, to prevent damage to the connectors during handling and assembly.

-

Design for Manufacturability

When designing PCB layouts, consider the manufacturability of the SMT connectors. Ensure the connectors are placed in locations easily accessible for assembly and inspection and avoid designs that may make it difficult to properly align or solder the connectors.

Conclusion

SMT connectors play a crucial role in PCB design and manufacturing. Understanding their various types, characteristics, and applications can help you make informed decisions when selecting the right components for your project. Whether you’re working on a simple circuit board or a complex system, these tiny connectors can make all the difference in ensuring reliable performance and connectivity.

Choosing the proper SMT connectors for your PCB project requires careful consideration of various factors, such as your budget, application requirements, and overall design goals. However, by keeping the shared tips and insights in mind, you can confidently navigate the world of SMT connectors and make informed decisions that support your project’s success.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days