In electronics, reliability is crucial. Spring-loaded contacts have evolved to meet modern technology needs, ensuring uninterrupted signal flow. This write-up covers everything, from their intricate mechanisms to their vital role in electronic reliability, performance excellence, and future trends. So, let’s bring the details to the table!

The Basics Of Spring-Loaded Electrical Contacts

Historical Context

In technological evolution, spring-loaded electrical contacts have a rich history. Originating in early electrical engineering, they emerged to address the growing need for reliable connections as technology advanced.

From their early forms to today’s sophisticated versions, these connectors have played a crucial role in electronic connectivity across various applications.

Definition and Functionality

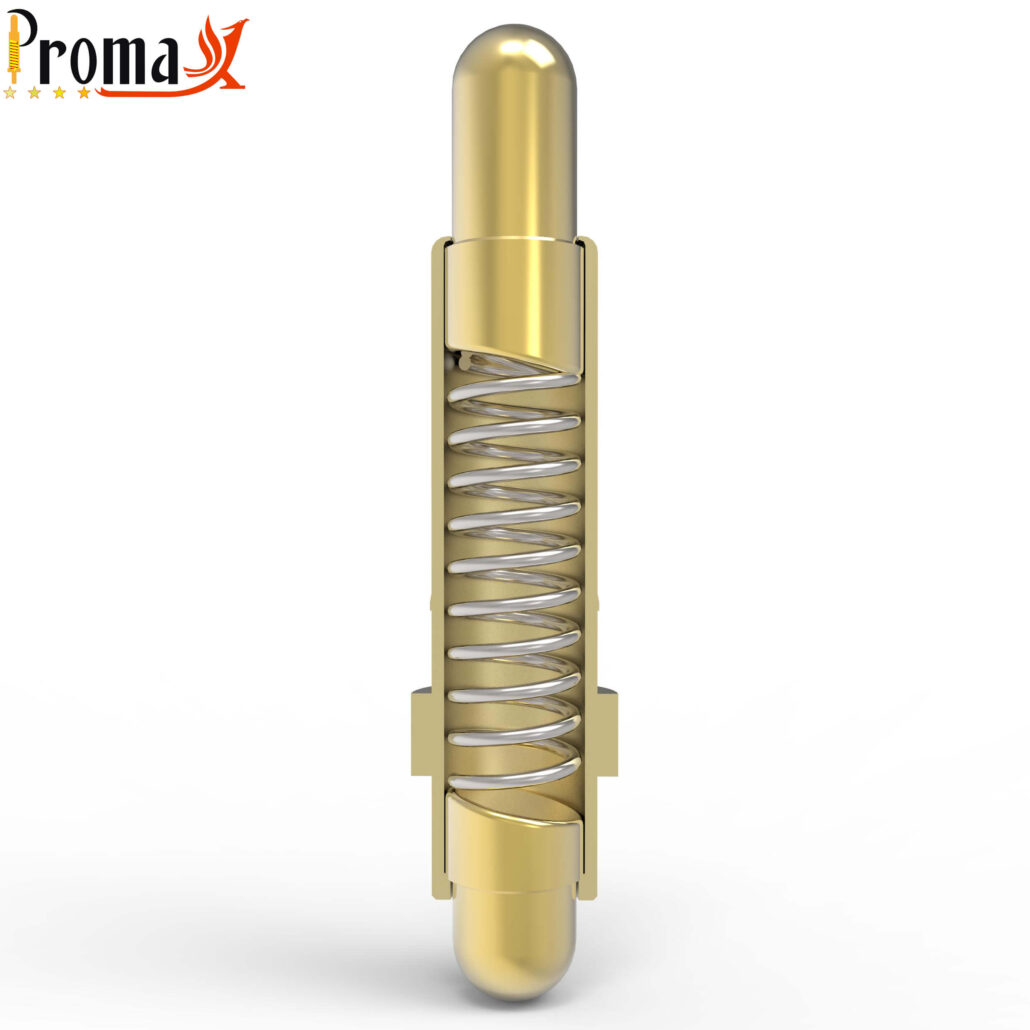

A spring-loaded electrical contact is a simple and efficient innovation. It features a coiled spring within a connector, ready to establish a reliable electrical connection.

The core principle is elegant: the spring provides controlled force, ensuring consistent connectivity. These connectors go beyond physical contact, adapting to surface irregularities and environmental factors, ensuring stability in diverse conditions.

How Spring-Loaded Contacts Work?

Understanding The Components and Construction

Spring-loaded contacts consist of meticulously crafted components. The central element is the spring, often made from materials like beryllium copper for flexibility and resilience.

The housing, overlooked but vital, provides insulation, protection, and structural integrity for optimal performance. Surrounding the spring is a choreography of materials chosen for electrical conductivity, corrosion resistance, and durability.

Working Mechanism

The working mechanism of spring-loaded electrical contacts revolves around their ability to provide a reliable and adaptive electrical connection. This mechanism is based on the fundamental principles of the spring, housing, and contact materials.

Spring Mechanism

The magic of spring-loaded contacts lies in their spring mechanism. The tightly wound coil stores energy during engagement, creating a controlled bounce effect that maintains constant pressure on contact surfaces.

This mechanism compensates for surface variations, ensuring a reliable connection. The spring’s ability to absorb shocks and vibrations enhances the connectors’ reliability.

Contact Material

Precision-chosen materials, often gold or silver-coated, provide excellent electrical conductivity and corrosion resistance.These materials are selected for compatibility with challenging electronic environments, contributing to the resilience and effectiveness of spring-loaded contacts.

Housing

The housing, a supporting yet crucial component, shields delicate parts from external elements.

Designed for insulation, robustness, and easy integration into electronic systems, it ensures the performance of spring-loaded contacts remains uncompromised in real-world challenges.

Understanding The Bounce Effect

When spring-loaded contacts connect, they bounce due to stored energy in the coil spring. As the plunger makes contact, the spring releases energy, making the plunger oscillate. This bouncing, though unexpected, is crucial for a reliable connection.

Importance of Controlled Bouncing in Electrical Contacts

Controlled bouncing overcomes initial resistance and surface imperfections, ensuring a reliable connection. This bouncing effect also maintains continuous contact despite vibrations, shocks, or minor movements between components.

Impact on Signal Integrity and Reliability

Controlled bouncing directly affects signal integrity and overall reliability. Allowing the plunger controlled bounce compensates for interruptions due to surface variations or environmental factors.

It is vital in applications prioritizing signal integrity, like high-frequency data transmission or precise electronic measurements.

How Do Spring-Loaded Contacts Bounce?

Making Contact: The Initial Connection

When spring-loaded contacts approach, the plunger compresses the spring as mating surfaces come together. The initial contact happens as the plunger connects with the opposing conductive element.

Maintaining Connection: The Role of the Spring

After the initial connection, the spring ensures a stable electrical connection. Its constant force keeps the plunger in contact, compensating for variations or movements during device operation.

Breaking Contact: The Release Mechanism

To disconnect, the release mechanism separates components, retracting the plunger. Controlled release minimizes bouncing, preserving contact longevity and preventing excessive wear or damage.

Types Of Spring-Loaded Electrical Contacts

Spring-loaded electrical contacts, tailored to specific needs, come in three main types:

-

Pogo Pins

Versatile connectors used in electronics, Pogo Pins have a spring mechanism in a barrel, allowing vertical compression for reliable connections in challenging scenarios.

-

Spring-Loaded Connectors

These connectors, in various forms like pins or sockets, use the spring-loaded principle for flexibility in electronic applications.

-

Spring-Loaded Test Probes

Specialized for circuit testing, these probes have a spring-loaded pin in a barrel, making contact with the test point under applied pressure.Understanding these distinctions reveals the diverse design and functionality of spring-loaded electrical contacts.

Design Considerations For Spring-Loaded Contacts

Material Selection

Choose materials wisely for reliable and lasting performance.

- Beryllium Copper: Excellent conductivity and resilience make it ideal for the spring, enduring repeated cycles without deformation.

- Gold or Silver Coating: Enhances conductivity, resists corrosion, ensuring a stable connection.

- Insulating Materials: Used in housing to prevent electrical interference, enhancing safety.

Spring Design And Properties

Critical considerations for optimal functionality.

- Material Elasticity: Carefully choose spring material elasticity for repeated compression and release without loss of properties.

- Force Characteristics: Design ensures the right force for contact maintenance, accommodating surface variations.

- Fatigue Resistance: Crucial design factor for extended operational lifespan under numerous cycles.

Environmental Considerations

Adaptability to diverse environments is key.

- Temperature Range: Materials must maintain properties within specified temperature ranges.

- Moisture and Corrosion Resistance: Components resistant to harsh environmental conditions.

- Chemical Compatibility: Choose materials resisting chemical degradation.

Customization Options

Spring-loaded contacts adapt to specific applications.

- Size and Form Factor: Tailor size and form to fit available space.

- Contact Configuration: Adjust contacts based on electrical requirements.

- Special Coatings: Apply coatings for high performance in unique environments.

- Mounting Options: Offer flexibility in mounting to accommodate various assembly designs.

By carefully considering these considerations, designers ensure spring-loaded contacts meet specific application demands.

Advantages Of Using Spring-Loaded Electrical Contacts

Spring-loaded electrical contacts offer a myriad of advantages, making them indispensable in the world of electronics.

Enhanced Reliability: Standing the Test of Time

Spring-loaded contacts are built for durability, ensuring a reliable and long-lasting connection in electronic devices.

- Continuous Contact Force: Maintains a steady force on contact surfaces, eliminating intermittent connections and ensuring a stable flow of electrical signals.

- Reduced Contact Resistance: The design minimizes signal loss, allowing efficient transmission between components.

- Long-Term Performance: Withstands repeated connections, offering durability, crucial for frequently engaged components.

Vibration and Shock Resistance: Keeping the Signal Steady

Spring-loaded contacts excel in dynamic environments, providing a steady signal in the face of vibrations and shocks.

- Immunity to Vibrations: Ideal for moving applications, ensuring consistent signal integrity in automotive electronics and machinery.

- Shock Absorption: Acts as a shock absorber, safeguarding components from sudden impacts.

- Connectivity in Harsh Environments: Thrives in extreme conditions, maintaining functionality in challenging surroundings.

Arc Suppression: Preventing Sparks and Damage

Spring-loaded contacts prevent sparks and damage during insertion and extraction, enhancing safety and connector lifespan.

- Low Insertion and Extraction Forces: Minimizes the risk of arc formation, enhancing safety and connector lifespan.

- Enhanced Current Carrying Capacity: Suited for high-power applications, providing reliable electrical performance.

Compact Design: Fitting into Tight Spaces

The compact design of spring-loaded contacts optimizes space on circuit boards, offering versatility and efficiency.

- Space-Saving Form Factor: Critical for miniature applications, enabling the design of smaller and more efficient devices.

- Flexibility in Mounting Options: Adapts seamlessly to diverse design requirements.

- Maximizing PCB Usage: Contributes to efficient component placement, streamlining electronic device design.

User-Friendly Installation and Maintenance

Spring-loaded contacts are user-friendly, simplifying both installation and maintenance processes.

- Simplified Assembly: Minimizes production time, enhancing efficiency in manufacturing.

- Easy Maintenance: Facilitates straightforward maintenance procedures, ensuring long-term device usability.

Applications Of Spring-Loaded Electrical Contacts

Electronics Industry Applications

- Printed Circuit Boards (PCBs): Essential in PCBs, spring-loaded contacts enable reliable signal transmission between different layers.

- Battery Contacts: Crucial for devices like laptops and phones, these contacts establish efficient power connections in battery-dependent electronics.

- Connectors for Portable Devices: Ideal for compact designs, spring-loaded contacts provide reliable connectivity in portable devices like smartphones and tablets.

Automotive Applications

- Automotive Connectors: Used in vehicles for sensors, lighting, and control modules, these contacts ensure robust connections despite challenging conditions.

- Battery Management Systems: Contribute to efficient power distribution and charging connections in automotive battery management systems.

- Infotainment Systems: Enable seamless communication between components in vehicle-infotainment systems.

Medical Devices And Healthcare Applications

- Medical Sensors: Employed in vital sign monitoring devices, spring-loaded contacts ensure reliable connections in medical sensors.

- Diagnostic Equipment: Facilitate precise connections in handheld devices and medical instruments for accurate readings.

- Patient Monitoring Systems: Ensure consistent connectivity in patient monitoring systems for continuous health tracking.

Aerospace And Military Applications

- Avionics Systems: Connect critical components in aircraft for reliable communication and operation.

- Military Communication Devices: Ensure dependable connections in military communication devices, electronic warfare systems, and radar equipment.

- Satellite Systems: Contribute to reliable connections in outer space conditions within satellite systems.

Consumer Electronics Applications

- Wearable Technology: Enable efficient charging and data transfer connections in smartwatches, fitness trackers, and other wearables.

- Gaming Consoles: Used for responsive and reliable controller connections in gaming consoles.

- Audio Devices: Facilitate clear and uninterrupted sound transmission in audio equipment like headphones and microphones.

Understanding the diverse applications of spring-loaded contacts highlights their crucial role in ensuring reliable and adaptable connections, contributing to the seamless functioning of electronic systems across various industries.

Spring-Loaded Electrical Contacts Vs Traditional Contacts

When assessing electrical contacts, comparing spring-loaded and traditional types is crucial. Let’s analyze the differences:

Key Differences And Why Spring-Loaded Contacts Are Better

Reliability and Longevity

- Spring-Loaded Contacts: Engineered for durability, providing a constant force for reliable connections over time.

- Traditional Contacts: May wear out, leading to reliability issues, especially with frequent connections.

Adaptability to Surface Variations

- Spring-Loaded Contacts: The bounce effect adapts to surface irregularities for consistent connections.

- Traditional Contacts: Lack adaptability, risking unreliable connections, especially in vibrating environments.

Shock and Vibration Resistance

- Spring-Loaded Contacts: Absorb shocks and adapt to vibrations, ideal for dynamic environments.

- Traditional Contacts: More prone to damage and intermittent connections in vibrating scenarios.

Arc Suppression

- Spring-Loaded Contacts: Controlled bounce minimizes arcs, enhancing safety and preventing damage.

- Traditional Contacts: May generate arcs, posing a risk of sparks and damage during connection.

Low Insertion and Extraction

- Forces Spring-Loaded Contacts: Require low forces, reducing arc formation and minimizing wear.

- Traditional Contacts: Higher forces may contribute to wear, especially in frequent mating cycles.

Consistent Contact Force

- Spring-Loaded Contacts: Maintain constant force, ensuring stable signal transmission.

- Traditional Contacts: Lack consistent force, leading to intermittent connections and signal instability.

In summary, spring-loaded contacts excel in reliability, adaptability, shock resistance, arc suppression, low forces, and consistent contact force. This superiority makes them the preferred choice for robust and dependable electrical connections across various applications.

Quick Table of Comparison: Spring-Loaded Electrical Contacts Vs Traditional Contacts

| Characteristic | Spring-Loaded Contacts | Traditional Contacts |

| Reliability and Longevity | Engineered for durability | Prone to wear and degradation |

| Adaptability to Surface Variations | Accommodate irregularities | Limited adaptability |

| Shock and Vibration Resistance | Designed to absorb shocks | More susceptible to damage |

| Arc Suppression | Controlled bounce minimizes arcs | Arcs may form during connections |

| Low Insertion and Extraction Forces | Require low forces | Higher forces contribute to wear |

| Consistent Contact Force | Maintain stable connections | Lack consistent force |

Future Trends And Innovations

Technological Advancements in Spring-Loaded Contacts

Smart Materials Integration

- Future Trend: Using smart materials for adaptive behavior in spring-loaded contacts.

Nanotechnology in Manufacturing

- Potential Advancement: Precision manufacturing with nanotechnology for smaller, more efficient contacts.

Wireless Connectivity Integration

- Impact on the Future: Exploring wireless integration for enhanced data transmission in electronic devices.

Potential Advancements In Design And Applications:

Miniaturization and Microelectronics

- Future Trend: Miniaturization for micro-scale contacts in compact devices and wearables.

Customization for Specific Environments

- Potential Advancement: Tailoring contacts for extreme conditions, expanding their applications.

Energy Harvesting Integration

- Impact on the Future: Integrating energy harvesting for increased device sustainability.

Impact On The Future Of Electronic Connectivity

IoT and Smart Devices

- Future Trend: Crucial role in connecting IoT and smart devices seamlessly.

High-Speed Data Transmission

- Potential Advancement: Design enhancements for higher data transfer rates.

Integration with Emerging Technologies

- Impact on the Future: Collaboration with 5G and edge computing for evolving connectivity demands.

Enhanced Durability for Harsh Environments

- Potential Advancement: Innovations for increased durability in aerospace, automotive, and military systems.

Spring-Loaded Electrical Contacts Maintenance And Troubleshooting

Maintaining Optimal Performance: Practical Tips

- Keep Contacts Clean: Regularly clean contacts to prevent dust or oxidation that hinders electrical conductivity.

- Inspect for Physical Damage: Routinely visually inspect for bent pins or wear that could affect performance.

- Ensure Proper Lubrication: Lubricate moving parts to minimize friction and extend the contact’s lifespan.

- Monitor Environmental Conditions: Be mindful of extreme temperatures, moisture, and corrosive substances, adjusting conditions accordingly.

Common Issues And Troubleshooting Techniques

- Intermittent Connections: Check for debris or oxidation, clean contacts, and ensure proper alignment during the engagement.

- Reduced Signal Quality: Inspect for contact wear or damage, consider upgrading to improve conductivity.

- High Insertion Forces: Inspect for misalignment or damage, lubricate moving parts, and ensure proper alignment.

- Arcing During Connections: Check lubrication, maintain low insertion forces, and inspect for wear to prevent arcing.

Importance Of Periodic Inspections And Replacements

- Preventive Maintenance: Regular preventive maintenance identifies and addresses issues before impacting performance.

- Detecting Wear and Tear: Periodic inspections detect wear, allowing timely replacements to prevent unexpected failures.

- Maintaining Consistent Performance: Regular replacements ensure consistent performance, reducing the risk of connections and signal degradation.

- Maximizing Operational Lifespan: Replacing components maximizes the operational lifespan, contributing to long-term reliability.

Conclusion

In short, spring-loaded electrical contacts are unparalleled components in ensuring reliable connections, even in dynamic environments.Offering enhanced reliability, consistent contact force, and reduced resistance, they excel in various applications.

Wanna elevate your connectivity experience? Reach Promaxpogopin, where performance meets precision and trust in a proven leader in electrical connectors.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days