A pogo pin is a type of contact used in electronic devices to make connections. They are named for using a pogo stick to create the necessary force to contact the mating part.

Pogo pins offer a stable and secure connection for transferring data, power, or signals between two devices. There are numerous types of pogo pins, each with a special set of advantages and disadvantages. This blog post will examine the various kinds of pogo pins and their applications.

What is Pogo Pin?

Pogo pins are metal spring-loaded pins used to make temporary electrical connections. The metal contacts on the tips of the pins are designed to create a reliable connection with a printed circuit board (PCB) while also being able to withstand repeated use.

Pogo pins are available in various sizes and styles, each of which is well-suited for a specific type of application.

Structure of Pogo Pin

Pogo pins have a cylindrical body with a conical tip. The metal contacts are located on the tips of the pins, and the spring-loaded mechanism is inside the pin’s body. Pogo pins are available in various sizes, from as small as 0.4 mm in diameter to as large as 6 mm in diameter.

The size of the Pogo pin you need will depend on the application for which you are using it.For instance, because they may fit in small locations, smaller pogo pins are frequently utilized in cell phones and other portable electronics.

On the other hand, larger pogo pins are typically used in heavy-duty industrial applications where they can better withstand repeated use.

How does Pogo Pin work?

Pogo pins work by using a spring-loaded mechanism to create a temporary electrical connection between two devices. When the pogo pin is pressed against a PCB, the metal contacts on the tip of the pin make contact with the copper traces on the PCB.

This creates an electrical connection that can be used to transfer data, power, or signals between two devices.The spring-loaded mechanism allows the pogo pin to make a secure connection with the PCB while also being able to withstand repeated use.

When not in use, the pogo pin is retracted into its body so that it does not make contact with the PCB. This prevents short circuits and other problems that can occur when two metals come into contact with each other.

Type of pogo pin

The most common types of pogo pins are:

- SMT/SMD Pogo Pin

- Through Hole Pogo Pin

- Double-Ended Pogo Pin

- High Current Pogo Pin

- Right Angle Pogo Pin

- Bending Type Pogo Pin

- Solder Cup Pogo Pin

- Thread Screw Pogo Pin

- SMT/SMD pogo pins: SMT (surface-mount technology) and SMD (surface-mount device) pogo pins are similar to standard pogo pins but have a smaller body that can be mounted directly onto a PCB.

- Through-hole pogo pins: Through-hole pogo pins are similar to standard pogo pins but have a longer body that extends through the holes in a PCB. This allows the pogo pin to be soldered directly to a PCB without the need for a separate soldering step. Through-hole pogo pins are typically used in applications where space is not a concern, such as in heavy-duty industrial applications.

- Double-ended pogo pins: Double-ended pogo pins have a metal contact on both ends of the pin. This allows the pogo pin to be used in applications where two electrical connections need to be made, such as in test fixtures.

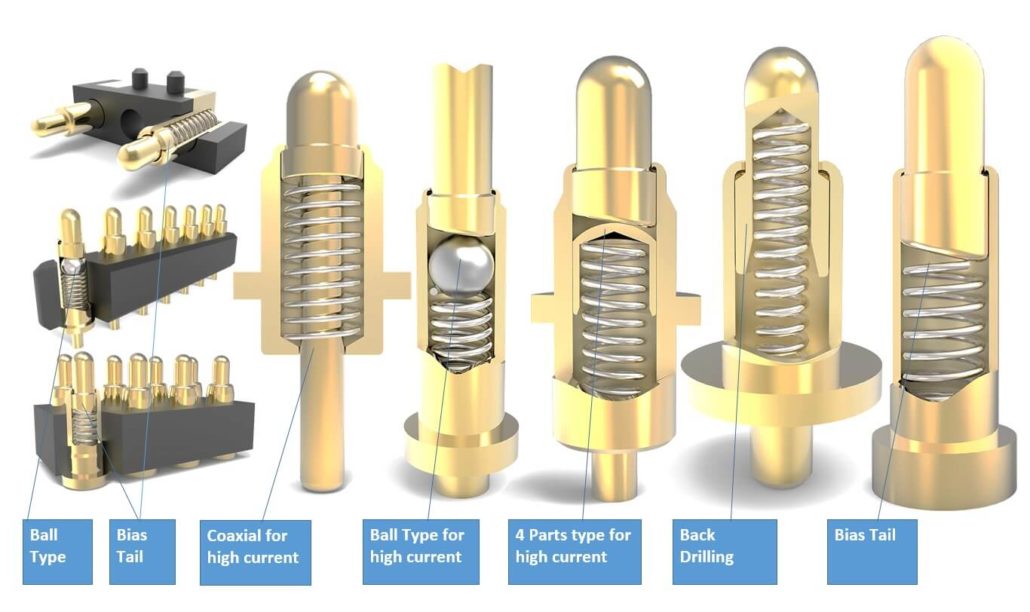

- High-current pogo pins: High-current pogo pins are designed to carry larger currents than standard pogo pins. They are therefore suitable for high-current applications like power supplies and charging stations.

- Right-Angle pogo pins: Right-angle pogo pins are similar to standard pogo pins but have a right-angle bend in the middle of the pin. This makes it possible for the pogo pin to be flush with the PCB surface. Right-angle pogo pins are typically used in applications where space is limited, such as in cell phones and other handheld devices.

- Bending-type pogo pins: Bending-type pogo pins are similar to standard pogo pins but can be bent into different shapes. Because of this, the pogo pin may be used in small spaces, such as mobile phones and other portable gadgets.

- Solder Cup pogo pins: Solder-cup pogo pins are similar to dip pogo pins, but they have a small cup on the end of the pin that can be filled with solder. This allows the pogo pin to be soldered directly to a PCB without the need for a separate soldering step.

- Thread screw pogo pins: Thread screw pogo pins are similar to standard pogo pins but have a threaded body that can be screwed into place. This allows the Pogo pin to be used in applications where a secure connection is needed.

Uses of Pogo Pin

Pogo pins are commonly used in a variety of applications, such as Computer peripheral devices, electronic test equipment, industrial machinery, telecommunication equipment, consumer electronics, cell phones, GPS devices, digital cameras, and video game consoles.

Pogo pins are used in various medical applications, such as blood pressure monitors, glucose meters, heart rate monitors, infusion pumps, and medical sensors. Pogo pins are also used in various military and aerospace applications, such as guidance systems, missile launch systems, and spacecraft control systems.

Small Pogo Pins

Small pogo pins are a versatile type of electrical connector used in various electronic applications. They are designed to fit into tight spaces, making them ideal for compact devices. Small pogo pins maintain a reliable connection while being able to withstand mechanical stress.

Examples of Small Pogo Pins

Miniature Pogo Pins

Miniature pogo pins are slightly larger than micro pogo pins but still compact. They are commonly used in consumer electronics, such as smartphones and tablets, where space is limited. Miniature pogo pins provide a stable connection for data transfer and power supply, making them essential in modern devices.

Micro Pogo Pins

Micro pogo pins are the smallest variant, designed for ultra-compact applications. They are often found in wearables and other miniaturized electronics. Micro pogo pins allow for high-density arrangements, enabling multiple connections in a very small footprint. Their design ensures a reliable electrical connection while fitting into the tightest spaces.

What’s the Difference Between Miniature Pogo Pins and Micro Pogo Pins?

The primary difference between miniature pogo pins and micro pogo pins lies in their size and application. Miniature pogo pins are slightly larger and can accommodate more robust applications, while micro pogo pins are designed for the most compact devices. Both types offer the same functionality, providing reliable electrical connections, but their size determines their suitability for different electronic devices.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days