Consumer electronics have rapidly evolved, transforming our lives and tech interactions. From the clunky, limited devices of the past to today’s sleek, multifunctional gadgets, it’s been astonishing.

Connectors, often overlooked yet profoundly vital, have silently powered this evolution.

They’re the unsung heroes, enabling power supply, data transfer, and more. Innovation is paramount with the growing demand for smaller, smarter, and more reliable pogo pin connectors.

This article explores a groundbreaking advancement: waterproof pogo pin connectors. We will delve into their definition, functionality, and significance for the future of consumer electronics. Let’s dive into this innovation.

The Evolution of Consumer Electronics

Consumer electronics gained momentum from the late 19th century and has seen significant growth in the mid-20th century with the introduction of televisions and radios.

The 1970s and 1980s brought about personal computers, fundamentally reshaping work and communication.As technology diversified, connectors became pivotal in powering these devices.

Today’s digital era demands smaller, efficient, and rugged electrical connectors.

This drive for innovation birthed waterproof pogo pin connectors, addressing consumer electronics’ evolving challenges.

Understanding Pogo Pin Connectors

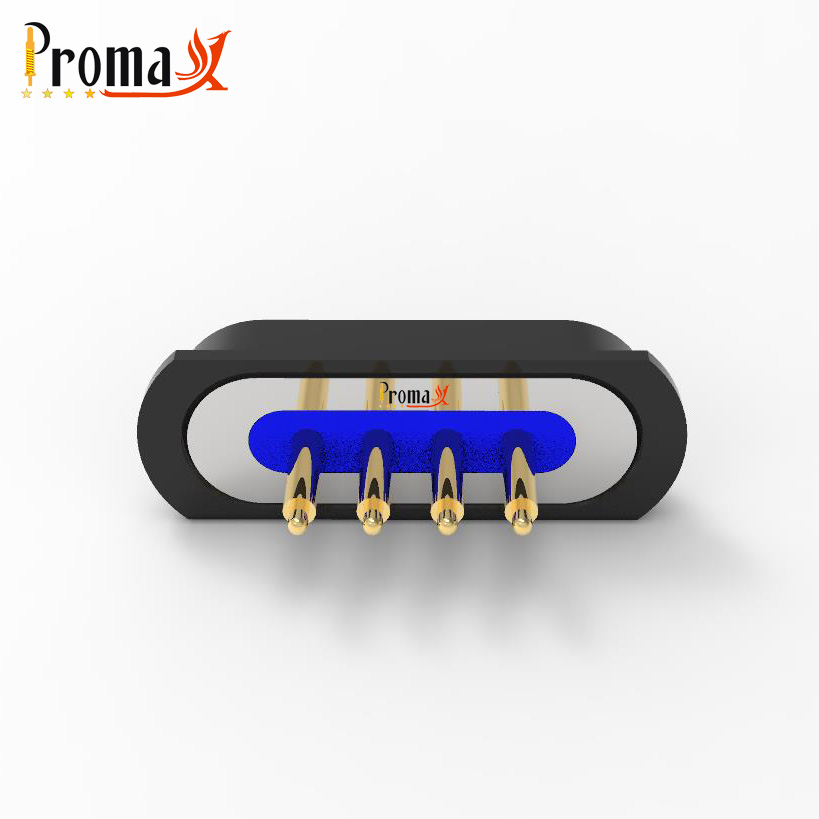

Pogo pin connectors, essential in electronics, are specialized for temporary electrical connections. They comprise a plunger (the pin) within a spring-loaded tube (the barrel). These connectors create secure, reliable connections through compression.

How Do They Work, and What are Their Components?

Pogo pin connectors work elegantly: depressing the plunger compresses the spring, allowing the pin to connect with another surface, typically a pad or circuit board contact point. It enables power or data transfer. Components include:

- Plunger: The conductive pin inside the connector.

- Barrel: Houses the plunger and spring, providing tension for a secure connection.

- Spring: Imparts the “spring-loaded” property, returning the plunger to its original position.

- Outer Housing: Surrounds the plunger and spring for durability.

Traditional Applications of Pogo pin connectors

Pogo pin connectors have served various roles for decades:

- Testing and Debugging: Common in electronics manufacturing and testing for quick, reliable connections during quality control.

- Battery Contacts: Often found in electronic device battery compartments, ensuring a secure connection to the device’s power supply.

- Docking Stations: Many smartphone and tablet docking stations use pogo pin connectors for charging and data transfer.

Waterproofing Technology: A Game Changer

The Significance of Waterproofing in Consumer Electronics

Waterproofing is of paramount importance in consumer electronics. Electrical devices are deeply integrated into our lives and face various environmental threats, with water being primary.

Whether it’s an accidental smartphone splash, exposure to rain in outdoor gadgets, or the need for underwater sensors, repelling water and moisture is crucial for durable electronics.

Waterproofing goes beyond accident protection. It enhances device durability and longevity, empowering users to use their gadgets in various conditions without worrying about damage, ultimately making electronics more versatile and resilient.

Challenges Faced in Making Electronic Connectors Waterproof

Waterproofing electronic connectors is complex due to their intricate design and potential water penetration points. Engineers face significant challenges:

Sealing Complexity

Creating a seal to keep water out without affecting connector functionality is delicate. This seal must endure varying pressures, temperatures, and environmental conditions.

Material Selection

Choosing corrosion-resistant materials suitable for wet environments is crucial while maintaining electrical conductivity.

Precision Engineering

Waterproof connectors require precise design and manufacturing to ensure reliability even after prolonged moisture exposure.

Testing Rigor

Rigorous testing is essential to validate waterproofing capabilities, covering water ingress, pressure resistance, and long-term durability.

The Rise of Waterproof Pogo Pin Connectors

How Waterproof Pogo Pin Connectors Address Waterproofing Challenges?

Waterproof pogo pin connectors offer a comprehensive solution to the intricate challenges of waterproofing in consumer electronics. They employ precision engineering and advanced materials to overcome these obstacles:

Effective Sealing

These connectors feature specialized sealing mechanisms, creating robust barriers against water and moisture infiltration. These seals endure various environmental conditions, ensuring a reliable connection in wet settings.

Corrosion Resistance

Carefully chosen materials resist corrosion, enabling these connectors to endure water exposure without degradation, ensuring long-term reliability.

Precision Engineering

These connectors are meticulously engineered, with each component designed to fit seamlessly and maintain functionality even in wet conditions, reducing the risk of water ingress.

Rigorous Testing

Extensive testing validates waterproofing capabilities, including assessments for water ingress, pressure resistance, and durability under various moisture-related scenarios.

Waterproof Pogo Pin Connectors in Consumer Electronics

Smartphones

These connectors enable functional charging ports in smartphones even after exposure to water, enhancing device durability and user confidence in wet conditions.

Fitness Trackers

Wearable fitness devices, often exposed to sweat and water, rely on waterproof pogo pin connectors for charging and data transfer, ensuring seamless functionality in challenging environments.

Outdoor Gadgets

Devices used in rugged outdoor settings, including GPS units and action cameras, utilize waterproof pogo pin connectors to maintain connectivity even in adverse weather conditions.

Benefits of Waterproof Pogo Pin Connectors

The adoption of waterproof pogo pin connectors in consumer electronics yields several notable benefits:

Enhanced Durability

Devices equipped with these connectors are more robust and capable of with standing exposure to water, dust, and humidity. This increased durability extends the lifespan of consumer electronics.

Reliable Performance

Waterproof pogo pin connectors provide a reliable connection, even in harsh environments. This ensures consistent device performance and minimizes the risk of connectivity issues.

Versatility

These connectors empower consumers to use their devices in scenarios from underwater photography to outdoor adventures without worrying about damage due to moisture.

Longevity

Their resistance to moisture and corrosion ensures a longer lifespan for electronic devices, reducing the need for premature replacements.

Reduced Maintenance Costs

With fewer maintenance requirements, these connectors lead to cost savings for manufacturers and consumers.

Waterproof Pogo Pins vs. Traditional Connectors

To fully appreciate the innovation of waterproof pogo pin connectors, let’s compare them to traditional connectors:

Waterproofing Capabilities

- Waterproof Pogo Pin Connectors: Specifically designed to withstand water and moisture exposure with effective sealing mechanisms and corrosion-resistant materials.

- Traditional Connectors: Not inherently waterproof, vulnerable to moisture, leading to corrosion and connectivity issues.

Durability

- Waterproof Pogo Pin Connectors: Known for their robustness, offering increased durability in harsh environmental conditions.

- Traditional Connectors: Prone to wear over time, especially when exposed to moisture, dust, or temperature variations.

Maintenance

- Waterproof Pogo Pin Connectors: Typically require less maintenance due to resilience in various environments, reducing the need for frequent cleaning or replacement.

- Traditional Connectors: Often require more regular maintenance to prevent corrosion and maintain functionality.

Performance

- Waterproof Pogo Pin Connectors: Provide consistent and reliable performance, excelling in challenging conditions and maintaining electrical connectivity even when exposed to water.

- Traditional Connectors: May experience intermittent connectivity issues in wet or dusty environments, potentially impacting device performance.

Versatility

- Waterproof Pogo Pin Connectors: Versatile and suitable for a range of consumer electronics, enabling usage in diverse scenarios, including smartphones, wearables, and outdoor gadgets.

- Traditional Connectors: Limited resistance to environmental factors, making them less suitable for applications involving moisture or dust exposure.

Key Features and Components of Waterproof Pogo Pins

Waterproof pogo pin connectors are engineering marvels designed to provide reliable connections while safeguarding against moisture and environmental challenges.

Key Features

- Sealing Mechanism: Central to waterproof pogo pin connectors, it effectively blocks water infiltration for a reliable, dry connection.

- Corrosion-Resistant Materials: Utilizing materials like stainless steel and specialized alloys to resist corrosion in wet environments.

- Spring-Loaded Design: Maintains secure contact, accommodating pressure and alignment variations for dependable connections, even in adverse conditions.

- Low Contact Resistance: Designed to minimize resistance, ensuring efficient power and data transfer in damp environments.

- Dust Resistance: Many models are dust-resistant, adding an extra layer of environmental protection.

Materials and Benefits

- Stainless Steel: Commonly used for plunger and barrel components due to its corrosion resistance, ideal for prolonged wet use.

- Specialized Alloys: Employed for their strength and corrosion resistance, enhancing durability.

- Sealing Gaskets: Rubber or silicone gaskets create watertight seals, maintaining flexibility and resilience for effective moisture barriers.

Contribution to Waterproofing

- Sealing Mechanism: Effective water ingress barrier, safeguarding sensitive electrical components.

- Corrosion Resistance: Maintains structural integrity, preventing rust or material degradation over time.

- Spring-Loaded Design: Ensures continuous contact pressure, reducing water infiltration risks.

- Low Contact Resistance: Minimized resistance preserves efficient electrical connections even in moist conditions.

- Dust Resistance: Prevents fine particles from compromising connector integrity.

Innovative Applications of Pogo Pin Connectors

Waterproof Pogo Pin Connectors in Various Industries

Marine and Underwater Exploration

Integral in underwater drones, ROVs, and marine sensors, facilitating communication and power transfer in oceanic depths.

Healthcare

Used in medical devices and patient monitoring systems, ensuring reliable connections in sanitary and moisture-sensitive environments.

Automotive

Applied in navigation systems, entertainment consoles, and sensors for secure connections in vehicles exposed to rain and humidity.

Aerospace

Play a role in aerospace applications, including cockpit displays and communication systems, prioritizing reliability.

IoT and Wearable Technology

Waterproof pogo pin connectors are crucial in IoT and wearables:

- Data Transfer: Facilitate data exchange between wearables and data hubs for accurate health and fitness data collection.

- Charging: Simplify wearable device charging, enhancing user convenience.

- Environmental Sensors: Enable reliable operation of outdoor or wet-condition sensors, expanding environmental monitoring applications.

- Wearable Safety: Enhance the safety of underwater wearable technology for activities like swimming and diving.

Challenges and Solutions

Challenges in Implementing Waterproof Pogo Pin Connectors

- Complex Sealing: Maintaining conductivity while achieving a waterproof seal is a significant challenge.

- Miniaturization: Shrinking connectors for compact devices without compromising waterproofing is demanding.

- Environmental Toughness: Operating in harsh conditions, from extreme temperatures to chemicals, requires durability.

- Cost Management: Balancing affordability with waterproofing technology adds manufacturing complexity.

Solutions and Strategies

- Advanced Sealing Techniques: Innovative sealing methods like precision molding and gasket materials are under research for robust yet compact seals.

- Nanotechnology: Exploring nanoscale coatings and materials to enhance waterproofing while preserving compactness.

- Materials Engineering: Development of materials combining corrosion resistance and electrical conductivity to ensure reliable connectivity in wet environments.

- Testing and Certification: Rigorous testing and certification processes ensure adherence to industry standards, maintaining quality and reliability.

Insights into Ongoing R & D Efforts

- Materials Advancements: Research focuses on materials with improved conductivity and corrosion resistance.

- Miniaturization: Engineers aim to further reduce connector size for devices like smartwatches and earbuds.

- IoT Integration: Research emphasizes seamless integration of connectors into IoT devices for reliability in diverse environments.

- Sustainability: Efforts are directed toward eco-friendly materials and processes in alignment with sustainability goals.

The Environmental Impact

1. Reduced Electronic Waste

- Enhance device durability by resisting moisture damage.

- Reduce premature device replacements due to moisture-related issues.

- Facilitate easier repairs, extending device lifespan.

2. Extended Device Lifespan

- Encourage longer device usage, reducing the demand for new devices.

- Conserve raw materials, energy, and resources by extending device life.

3. Sustainable Design and Manufacturing Practices

- Choose sustainable materials, such as recyclable and corrosion-resistant options.

- Prioritize energy efficiency and eco-friendly production processes.

- Design for easy disassembly and recycling, minimizing environmental impact.

Future Prospects

Enhanced Integration and Miniaturization

Expect smaller, more integrated connectors to accommodate compact devices without sacrificing waterproofing.

Advanced Materials

Ongoing research will yield materials with superior conductivity, corrosion resistance, and sustainability attributes, enhancing connector performance.

IoT Revolution

Waterproof connectors will ensure reliable IoT device connectivity in various environmental conditions, driving smart homes and interconnected IoT ecosystems.

Wearable Technology

Waterproof connectors will enable seamless charging, data transfer, and integration in sophisticated wearables.

Sustainability Focus

The industry will prioritize eco-friendly materials and sustainable production, aligning with global sustainability goals.

Medical and Healthcare Applications

Increased adoption in diagnostic tools, remote patient monitoring, and healthcare innovations.

Aerospace and Marine Technologies

Crucial in aerospace and marine tech for reliability and environmental resilience.

Autonomous Vehicles

Contribution to autonomous vehicles through robust connections in onboard sensors and systems.

Cross-Industry Integration

Unexpected applications, such as agriculture, enable advanced sensor networks and precision agriculture practices.

Conclusion

Waterproof pogo pin connectors epitomize human ingenuity, offering resilient, reliable, and eco-conscious device connections in consumer electronics.Their evolution has reduced waste, extended device life, and fueled sustainable practices.

Looking ahead, they’ll empower smaller, smarter, and interconnected devices, driving IoT, healthcare, and transportation innovations.The message is clear: Embrace innovation, embrace waterproof pogo pin connectors. Together, we’ll forge a tech-savvy, sustainable future.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days