The origin of mate Connector

A connector is usually used to connect a conductor (wire) to an appropriate mating element to enable the current or signal of an electrical element to be switched on or off. Components and components, components and mechanisms, systems and subsystems between the electrical connection and signal transmission role of the device. Also known as mating contacts; plugs and sockets. It was derived from fighter aircraft manufacturing techniques. Aircraft in battle must be refueled and repaired on the ground, and the time spent on the ground was an important factor in winning or losing a battle.

That was why in World War II, the army was determined to shorten the time it took to repair on the ground. Firstly, they unified various control instruments and components and then integrated them into a complete system with connectors. When the faulty unit need to be repaired, it was taken apart and replaced with a new one, and the aircraft was immediately airborne. After the war, with the advent of computers, communication, and other industries, the connector from stand-alone technology has more development opportunities, and the market has rapidly expanded.

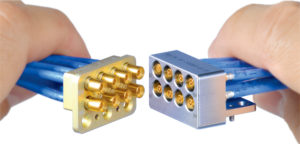

What can a mating connector be used to connect to?

From the connection function, the mating connector can realize the connection between the printed circuit, the base plate, equipment, and so on. The main implementation methods are divided into four types: the first is the IC component or component to the printed circuit board connection, such as an IC socket; The second is the PCB to PCB connection, typically such as a printed circuit connector; The third is the connection between the bottom plate and the bottom plate, typically such as a cabinet connector; The fourth is device-to-device connections, typically such as circular connectors. The highest market share is printed circuit board interconnects and equipment interconnects products.

Why use a mating connector?

Mate connectors are easy to mass-produce, easy to maintain, easy to upgrade, and improve design flexibility and other characteristics, widely used in aerospace, communications, data transmission, new energy vehicles, rail transit, consumer electronics, energy, medical, and other fields.

Application field expansion promotes the rapid growth of the market, and at the same time strongly promotes the development of connector technology. So far, the connector has developed into a complete range of products, rich specifications, various types of structure, professional direction subdivision, industry characteristics obvious, system standard serialization, and professional products.

The connector is not only used in smartphones, computers, and other items closely related to our life but is also widely used in all electronics-related terminal equipment. There is a wide variety of connectors because of the variety of design styles and uses they require.

There are four common mating methods for connectors

Connectors are essential components of all circuit systems. As a node, it can transmit current or optical signals to devices, components, equipment, and subsystems independently or together with cables, and keep no signal distortion and energy loss changes between systems. It is the basic component that constitutes the connection of a complete system. There are many ways to realize interconnection, let me introduce four common mating methods of connectors:

- Threaded connection: a connection often used for connector pin and socket with larger contacts and in strong vibration environments. After the connection is completed, a fuse or nut can be installed to prevent looseness, making it more reliable but making installation and disassembly slow.

- Bayonet connection is a reliable and rapid form of connection and separation. Most bayonet connectors correctly identify connection and locking, which can be seen through a small hole on the side of the connection nut.

- A push-pull connection is a multi-purpose connection. Common Push-pull connection has two kinds of structure, ball or pin, the connection form because there is no mechanical labor-saving mechanism, and the mechanical resistance increases significantly once mismatched but can be found in time.

- A cabinet connection is an electrical connector used for devices that need to be connected blindly near the frame. It makes electrical devices lighter, smaller, easier to maintain, and more reliable. The connector pin and socket usually use a floating or elastic contact design to ensure proper connection.

What are the advantages of EV mating connectors versus traditional mating connectors?

To meet the transformation and upgrading of the manufacturing industry and achieve the goal of industry 5.0, a new challenge to the connector, not only to have excellent performance, can be used in the harsh industrial environment, but also to meet the diverse needs of users for intelligent control equipment.

The traditional connector has been unable to meet this market demand, at this time, the EV mating connector came into being. EV mating connectors are designed for demanding applications. The EV mating connector mainly consists of three important parts: core, pin, and casing.

The core and pin form an electrical module to provide electrical connections to the equipment, while the shell is made of metal or thermoplastic materials, with a strong structure to provide reliable mechanical and environmental protection for electrical connections. The waterproof and corrosion-resistant metal housing ensures that EV mating connectors can work in harsh environments and meet the requirements of outdoor connections.

EV mating connector adopts modular design, expanding functions according to the needs of applications. It not only achieves barrier-free and fast connection between modular devices but also ensures the transmission of signals and power to meet the diverse connection requirements of applications. For users, it saves installation time, provides secure and reliable connections, and reduces overall production costs.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days