Precision machining is very important to modern industry. It can produce massive output in a short period of time, with zero defects or variations. It also guarantees highly efficient production, saving production costs and time. The best thing about precision machining is that it can be used on any product, from household items to complex industrial equipment. Precision machining also produces more marketable products than other methods of manufacturing. It also requires less effort than traditional methods, resulting in increased profitability.

What is CNC programming?

Computer numerical control (CNC)programming is the process of automatically generating numerical control machining programs with the aid of computers and corresponding computer software. Many beginners wonder what CNC programming is and how difficult it is.

The truth is that learning basic CNC programming is relatively easy, although advanced programs are more difficult to learn. Nonetheless, beginners should start with simple, small projects to get a feel for the software and its tools. Beginners should avoid tackling oversized or heavy pieces of work. Success with small projects will keep your motivation high, so you can move on to more difficult pieces.

CNC software is designed to control the machine with precise instructions. Incorrectly programmed software can lead to poor tolerances, surface finishes, and premature tool breakage. Operators should become familiar with the basic functions of CNC machines before learning to program them.

There are two main kinds of CNC programming: CAM and conversational. CAM is better for designing complex shapes, while conversational programming is great for learning the basics. By practicing manual programming, operators can improve the quality of their CAM outputs.

What are CNC machines?

CNC machines are highly useful in many industries. They can cut materials precisely without causing too much heat or interference with the machine’s use. They can also be programmed without disrupting production. Precision machining requires extreme accuracy, and the CNC machine is specifically designed for this. It will be beneficial to manufacturers of everything from automobiles to aerospace.

Here are some examples of precision machining: Precision machining can accelerate the development of your products. From prototypes to full-scale production, CNC machines will streamline the workflow. With their high degree of accuracy, developers can rapidly develop functional designs and then scale them up when demand is high. This will reduce turnaround times and costs associated with missed opportunities.

CNC machining is also an efficient way to get your product to market. In addition to their increased efficiency, CNC machines are a valuable investment for manufacturers. Today’s consumer electronics are becoming smaller and more powerful. These products must remain lightweight and compact. CNC micromachining and small-scale machining can handle specialized materials and hold tight tolerances for the smallest components.

Precision CNC machines can produce a wide variety of production parts and are highly versatile, offering high reliability and flexibility. Many CNC machines are also equipped with integrated CAD/CAM solutions. These advantages make them a great choice for precision machining.

What are machined parts?

The term “precision machining” refers to the art of creating a precise part through a series of complex processes. The process of precision machining requires proper engineering and design work to be carried out before the actual machining process can take place.

It is necessary for precision parts in many industries, from simple blanks with a few holes to intricate housing geometry. While the terminology can be confusing, precision machining is vital for any part that must be made accurately. The precision of a machining process is important in many areas, including the automotive, aerospace, and medical industry.

Despite the high level of sophistication of the equipment, a single flaw in a machined part could have disastrous consequences. Aerospace parts can malfunction in mid-flight, while medical devices can suddenly stop working. High-precision machining ensures high quality and produces parts within tight tolerances. It also saves time and production costs and guarantees highly efficient production.

What is milling machining?

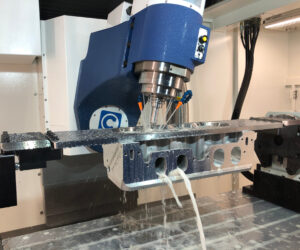

Milling machining is a type of CNC machining that entails the use of a circular tool with a number of cutting edges arranged symmetrically around an axis. The workpiece is usually clamped in a vise or a table that can be moved in three perpendicular directions.

The cutter is a disk or barrel clamped through its center to an arbor attached to the machine’s spindle. The cutter is also called an end mill, which is a cutter with a tapered shank and cutting teeth on its face and spiral blades on its lateral surface. The milling process can also be considered the most common operational machining process. The machine can be used to shape stock materials from start to finish.

This is because it gradually removes material to create the desired part features. The tool uses tiny cuts to produce a part with a precise or approximate shape. The speed and feed rate of the milling process is determined by the material’s size and complexity, as well as the tool used to produce it.

What is turning to the machine?

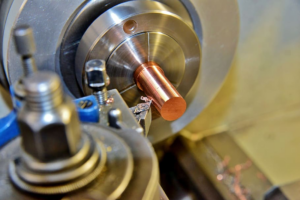

The term “turning machining” describes a process used to manufacture parts with a cylindrical shape, such as a wheel, crankshaft, or other rotating parts. The turning process is most often performed on a lathe. The parts produced by turning can be axisymmetric, and rotational, and have a variety of characteristics. Some parts require several operations, while others only require one operation. Here is a description of the different types of turning.

There are two types of turning operations: rough and finish. Rough turning involves the rotation of the workpiece next to a rotating cutting tool, with the aim of removing as much material as possible in the shortest time possible. It produces an essentially cylindrical shape. Fine-tuning requires the cutting depth to be small, the amount of cutting is also small, need to ensure the size of the product tolerance and surface roughness requirements. Both types of turning to require a sharp cutting tool. Both techniques are used to manufacture a wide variety of parts. In general, turning involves a process in which a workpiece is rotated relative to a tool.

The workpiece provides the energy for this process, and the cutting parameters that determine the speed and depth of the cut are influenced by the workpiece, tooling material, and dimensions. The cutting speed of ordinary steel using high-speed steel turning tools is between 25 and 60 m/min, while the cutting speed of coated hard metals can reach 300 m/min. Turning operations are also separated into three general categories, roughing and finishing, and semi-finishing.

How are Pogo Pin connectors’ barrels and plungers machined?

Let’s first look at how the plunger is processed. Let’s take a plunger with an outer diameter of 1.0mm and reverse drilling as an example. First of all, usually used a length of 2 meters and an outer diameter of 1.5mm. The first step is that the precision CNC lathe will first trim the end face of the copper bar. The second step is to drill the desired hole shape with a drill. In the third step, with the tool processing the desired size;

Finally, cut off; The plunger we want is finished. Let’s look at how the barrel is made. Similarly, let’s take a flat bottom barrel with an outer diameter of 1.5mm. First of all, usually used is a length of 2 meters and an outer diameter of 2mm. The first step is that the precision CNC lathe will first trim the end face of the copper bar. The second step is to drill the desired hole shape with a drill. In the third step, with the tool processing the desired size; Finally, cut off; The barrel we want is finished.

Conclusion

Precision machining is essential for various industries. It helps in producing components that have high dimensional accuracy and complex shapes, as well as different materials. High-quality machining reduces the rejection rate of products, which in turn results in increased productivity and reduced costs. The CNC machine is capable of performing a variety of operations, including cutting and turning, and can perform many different functions.

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days