Spring Probe

Spring probes, also known as spring contact probes, are specialized connectors designed to provide reliable electrical connections in various applications, particularly in harsh environments.

At Promax Pogo Pin manufacturer, we offer high-performance Spring Probes, designed to meet the needs of industries such as telecommunications, automotive, medical, and electronics. Our spring probes are expertly crafted to provide consistent, reliable connections, even in the most challenging conditions.

SIZE

DiameterΦ:≥0.7mm, full stroke ≥0.2mm, working stroke ≥0.05mm

SHAPE

all types of customization

MATERIAL

Brass, SUS304/316F/L,CuTe,HBi59,Cu-Sn, etc

PLATING

Au, Ag, Pd, Pt, Rh, Ru, Ni, etc

MOQ

3000pcs by T&R, Tray, Tube, Box, PE bag, etc

DELIVERY

DHL, UPS, ship the sample out in 2 weeks, mass production in 3-4 weeks

Spring Probe: Design and Functionality

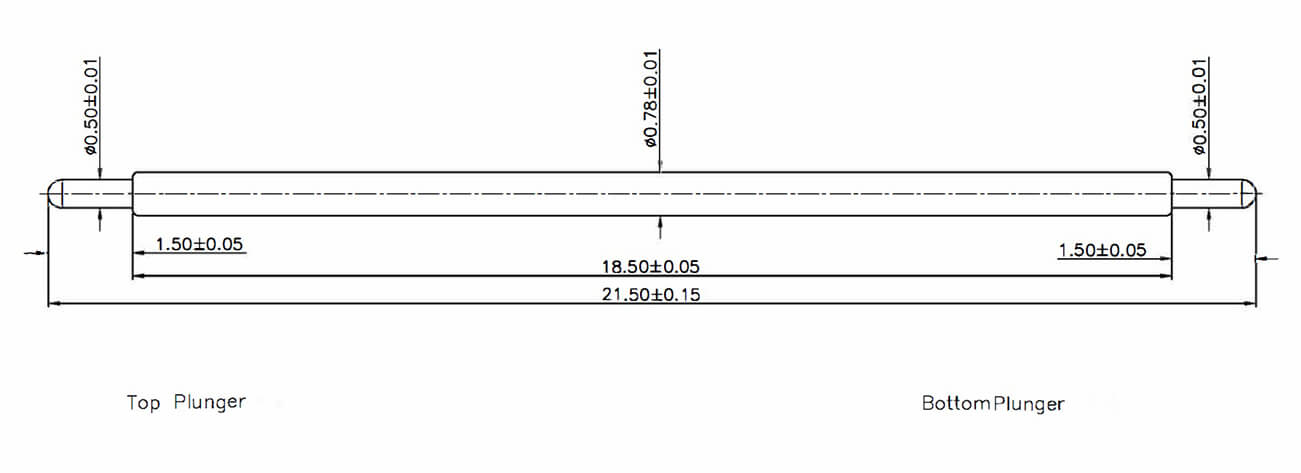

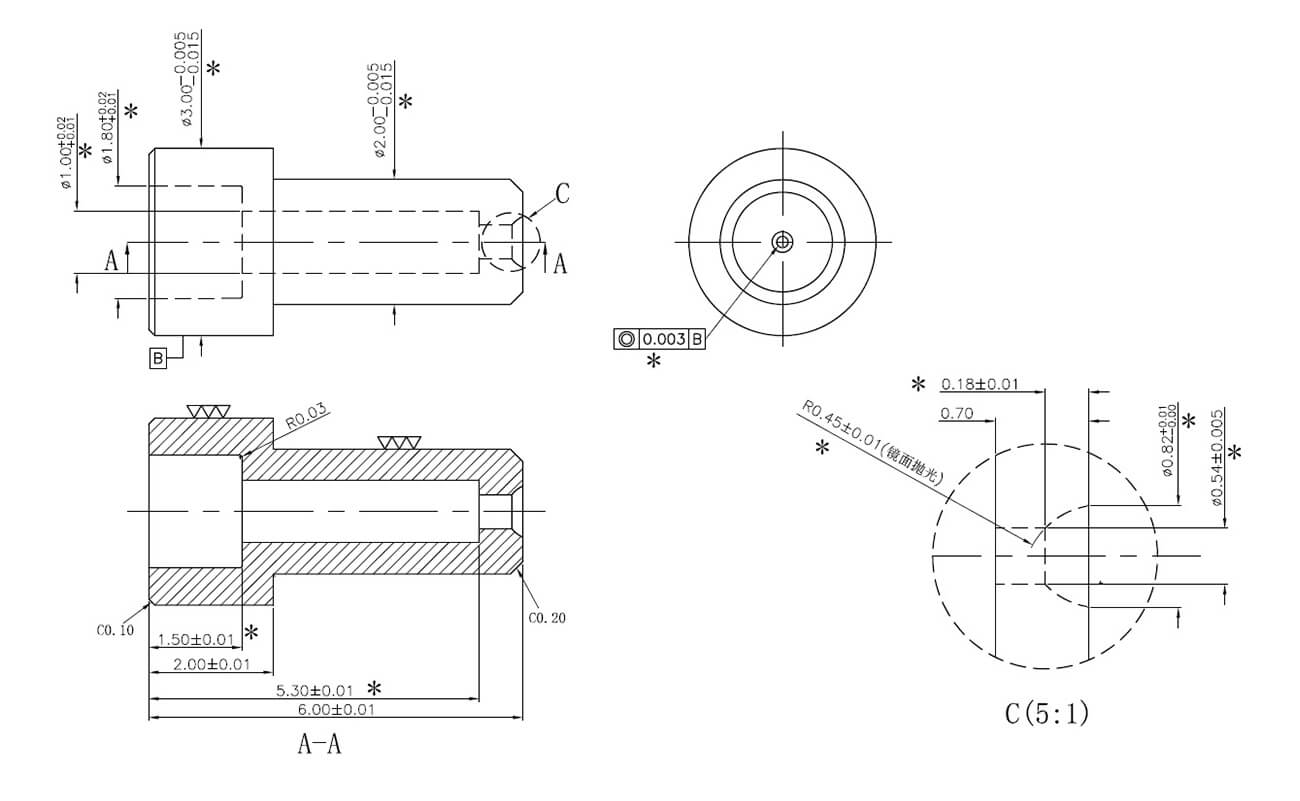

- Basic Structure: A spring probe typically consists of a barrel, a plunger, and a spring. The plunger is mounted within the barrel and is biased by the spring, allowing it to move freely. This design enables the probe to maintain contact with a mating surface even under conditions of shock, vibration, or misalignment.

- Contact Mechanism: The contact point of the spring probe is designed to engage only the surface of the target, rather than inserting into it like traditional pin and socket connectors. This allows for a forgiving mating process, accommodating misalignments and reducing the risk of damage during connection

For a detailed overview of their features and uses, check out our guide on spring-loaded pogo pins.

Spring Probe: Performance Characteristics

Electrical Performance: Spring probes are known for their low contact resistance, typically less than 10 mΩ, which is crucial for maintaining signal integrity in both analog and digital applications. They can handle high frequencies, with capabilities of up to 20 GHz and data rates of 12 Gb/s

Current Rating: Depending on the specific design, spring probes can support various current ratings, with some capable of handling up to 30 Amps

Temperature Range: These probes can operate effectively across a wide temperature range, typically from -55°C to 250°C, with some materials allowing for even more extreme conditions

Spring Probes Common Applications

- Harsh Environments: Spring probes are ideal for applications in industries such as aerospace, military, automotive, and industrial automation, where they can withstand extreme conditions. Their durability and reliable performance make them comparable to advanced solutions like waterproof pogo pin connectors, which are specifically designed to maintain functionality in harsh environments.

- Modular Components: They are often used in modular designs where quick disconnects are necessary, allowing for easy maintenance and replacement of components.

- Blind Mate Applications: The unique design of spring probes allows for blind mating, where the connector can engage without direct line of sight, making them particularly useful in compact or difficult-to-access spaces.

What is Spring Probe’s Structure?

The spring probe is the contact medium for electrical testing and is a high-end precision electronic hardware component. It mainly consists of three parts: spring, plunger, and barrel. Read More ReadLess

What is The Working Principle of The Spring Probe?

Testing whether the dut is working properly can give the manufacturer feedback on their process problems. Meanwhile, It can screen out the bad products to reduce the waste of subsequent finished products. Read More ReadLess

What is The Material and Surface Treatment of the Spring Probe?

| Main Materials | |

|---|---|

| Aluminum | AI6061, AI6063, AI6082, AI7075, AI2024, AI5052, A380, etc. |

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q3458, 20#, 45#, etc. |

| Brass | C35600, C36000, C37000, C37700, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper | C11000, C12000, C12200, C10100, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc. |

| Surface Treatment | |

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating. etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Carburized, Powder Coated |

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Power Coated, Nickel Plated, etc. |

| Plastic | Plating gold(ABS), Painting, Brushing(Acylic), laser engraving |

What is Spring Probe Tip Type?

Spring probe is widely used in electronic products such as mobile phones and plays a test role. The spring probe is equivalent to a medium. During the test, the head of the probe can be used to contact the object to be tested,

Read More

ReadLess

How to Choose The Right One?

It is important to choose a good one that will help you to check whether the semi-finished product is qualified or not. A qualified product is crucial for any company. So how do you choose a good one?

Read More

ReadLess

Why Promax Pogo Pin?

When it comes to test probes, few companies can match the level of skill and expertise demonstrated by Promax Pogo Pin. With over 15 years of experience in the field.

Read More

ReadLess

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days