Did you know? Molex Connectors initially used for connecting radio tubes in TVs, have revolutionized the electronics industry.

Electric Connectors play a crucial role in transmitting power or data signals between components in different devices and equipment. Products ranging from consumer electronics to industrial machinery and automobiles use Molex connectors due to their dependable performance and rugged durability. This blog article will delve into the world of Molex connectors, examining what makes them exceptional and why they remain a top choice for engineers and technicians. All the information about Molex connectors is here for you. So, get ready to learn about them in-depth!

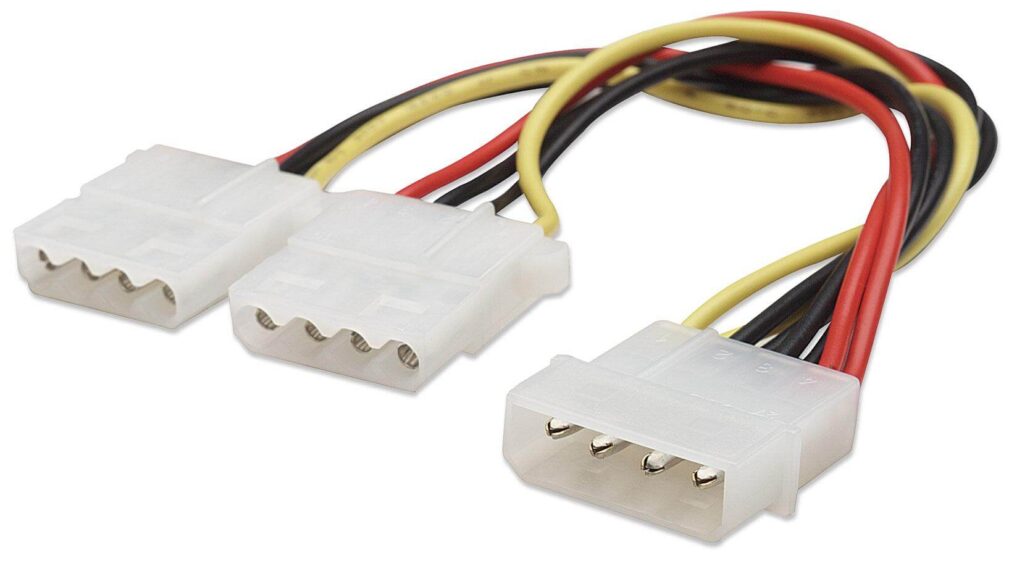

Molex Connector

A Molex connector is an electrical connector used to transmit power or data signals in various applications. They are designed for numerous industries, including computer hardware, automotive electronics, telecommunications, and industrial controls.

The Parts of a Molex Connector

- Housing: The outer plastic casing holds the pins and protects the electrical connections.

- Pins: The metal conductors are inserted into the housing and contact the corresponding socket or header.

- Terminal: This is the component crimped to the wire and inserted into the pin.

- Retention Clip: The component keeps the connector securely attached and stops it from becoming detached.

- Latch Lock: This is the mechanism that locks the connector in place when inserted into the socket or header.

- Contact Pads: The points on the socket or header that make electrical contact with the pins.

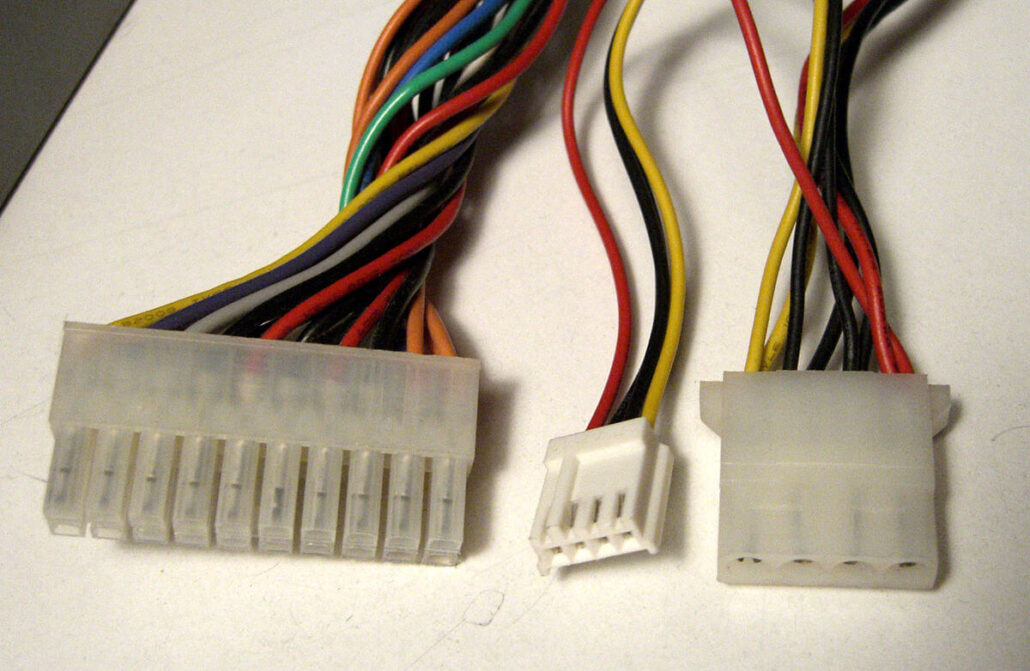

Types of Molex Connectors

-

Pin & Socket Connectors

Pin & Socket connectors, a kind of Molex connector, are the most commonly found type in a vast array of applications. Such connectors feature a male pin that inserts into a female socket, coming in a single- or dual-row layout.

-

Micro-Fit Connectors

Micro-Fit connectors are designed for applications requiring high-density connections, such as small form-factor computers. They are available in both male and female configurations and are designed for a secure connection in tight spaces.

-

Mini-Fit Jr. Connectors

Mini-Fit Jr. connectors are smaller versions of the standard Molex connector, designed for applications with limited space. They are also available in male and female configurations and can handle high current levels.

Other Types of Molex Connectors

In addition to the above-mentioned types, Molex connectors have multiple other types, including terminal block connectors, wire-to-board connectors, and many more.

Key Features of Molex Connectors

-

Durability

Molex connectors, made of resilient, top-notch materials, offer outstanding durability and dependability. As such, they can operate in the most arduous conditions, rendering them suitable for multiple industrial applications.

-

Reliability

Noted for dependability, their structure guarantees a stable and trusted connection throughout use. Manufactured to abide by industry rules, they are strictly tested to ensure they exceed all expectations.

-

Ease of Assembly

Molex connectors are designed for easy and efficient assembly, with a simple and intuitive design that makes them easy to use and install. This makes them a popular choice for engineers and technicians who need to quickly and easily connect components.

-

Versatility

They are versatile and can be used in a range of applications, from small hobby projects to large-scale industrial systems. With their different sizes, shapes, and designs, they are suitable for various settings.

Applications of Molex Connectors

-

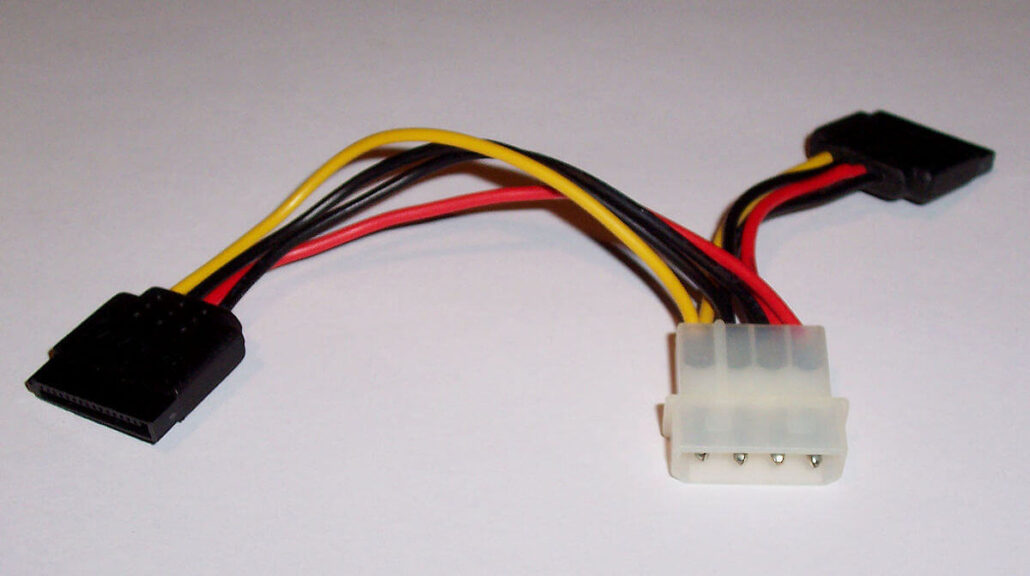

Computer Hardware

In computer hardware, Molex connectors are popular for connecting hard drives, printers, and other peripherals. Thanks to their reliability and stability, these connectors can ensure data and power is transmitted accurately and consistently.

-

Automotive Electronics

Automotive electronics like engine control systems, lighting, and audio systems require dependable connections and are thus fitted with Molex connectors. These components are made to survive even the most demanding conditions found in vehicles.

-

Telecommunications

From data centers to network equipment, Molex connectors are frequently employed in telecom to provide dependable, enduring connections that guarantee accurate power and data transmission.

-

Industrial Controls

Molex connectors are invaluable to industrial control systems, ranging from factory automation to energy management.

How to Choose the Right Molex Connector?

-

Consider the Operating Environment

Before selecting a Molex connector, it is essential to evaluate the surroundings where it will be utilized. For instance, if the connector will be used in a location that experiences extreme temperatures or copious amounts of moisture, you should choose a connector designed to endure such situations.

-

Choose the Right Contact Termination

Molex connectors are available in a variety of contact terminations, including crimp, compression, and IDC (insulation displacement contact). Picking the most suitable contact termination for your project will depend on various factors like the size and type of wire or cable used and the precise necessities of the application.

-

Determine the Right Contact Plating

Contact plating is an essential factor in the performance and longevity of a Molex connector. The two most common contact platings for Molex connectors are tin and gold. Tin plating is a cost-effective option that provides good electrical conductivity, while gold plating offers excellent conductivity and corrosion resistance. To ensure the proper Molex connector is chosen for your specific application, one should evaluate their requirements and pick the contact plating that is most suited.

-

Consider the Current Rating

Finally, you should consider the current rating when choosing a Molex connector. The current rating denotes the maximum electricity the connector can handle securely. Factors such as the magnitude of power going through the connector and the wire size should be considered to select the ideal current rating for your project.

How to Install a Molex Connector?

Successfully fitting a Molex Connector is simple when following the appropriate guidelines.

- Before installing the Molex Connector, strip the wires to the correct length and tin the wires with a small amount of solder. This will make it easier to insert the wires into the connector.

- Insert the wires into the appropriate slots in the Molex Connector. Ensure the cables are appropriately positioned and fully seated within the connector.

- Securely attach the connector to the wires with a Molex crimping tool to create a reliable connection.

- Before finalizing the installation, test the electrical connection by applying a small voltage to the Molex Connector. Ensure that there is no electrical resistance or voltage drop in the connection.

- Once you have confirmed the connection is secure and reliable, finalize the installation by applying heat-shrink tubing or electrical tape over the connection. This will provide additional protection and prevent any accidental short circuits.

Configuration of a Molex Connector

The configuration of a Molex Connector refers to the arrangement of the individual contacts within the connector and how they are wired.

Molex Connectors are available in a wide range of configurations, including single-row, dual-row, and multi-row configurations with varying numbers of contacts.

-

Single-row Configuration

It contains a solitary row of pins embedded within its housing, primarily used in low-density cases where only a few signals require transmitting.

-

Double-row Configuration

The housing of this configuration is equipped with two rows of pins and is most frequently used for applications that need to transmit a higher volume of signals but necessitate a compact design.

-

Multi-row Configuration

It is composed of several rows of pins within a housing and is commonly used for high-density situations requiring a significant amount of data transmission, but lack of space is not a hindrance.

Troubleshooting Tips for Molex Connectors

Here are some common issues with Molex Connectors and troubleshooting tips to help you resolve them:

-

Loose or Intermittent Connections

If you’re experiencing issues with loose or intermittent connections, it’s likely due to improper assembly or installation. Double-check the connections to ensure that the pins are properly seated and tightened.

-

Corroded or Dirty Contacts

Corrosion or dirt buildup on the contacts of the Molex Connector can lead to inefficient functioning or total shutdown. You should use contact cleaner to thoroughly clean the contacts or lightly sand them to eliminate rust.

-

Bent or Damaged Pins

To ensure the optimal functioning of the Molex Connector, inspect the pins for any signs of damage or malformation. If needed, replace any that have been compromised.

-

Overheating

Overheating can cause damage to the Molex Connector and may indicate an issue with the current flow. Check the current flow to ensure it is within the recommended range, and inspect the Molex Connector for any damage.

-

Electrical Arcing

If you’re experiencing electrical arcing, it’s likely due to high voltage or high current flow. Check the voltage and current flow and make any necessary adjustments to ensure that they are within the recommended range.

By following these tips and troubleshooting procedures, you can ensure your Molex Connectors continue to provide reliable and durable connections for your application. If you’re still experiencing issues, it’s recommended to consult with a Molex Connector expert or technical documentation for further assistance.

Conclusion

Molex connectors are an essential component in a wide range of applications, from computer hardware to telecommunications and beyond. They are constantly evolving to meet the changing needs of various industries. It is expected the innovations in material, technology, and design in the coming years will enhance the features of Molex connectors and make them more dependable and resourceful. Ultimately, if you desire a top-tier, multi-functional electrical connector, the Molex Connector is worth taking into account.