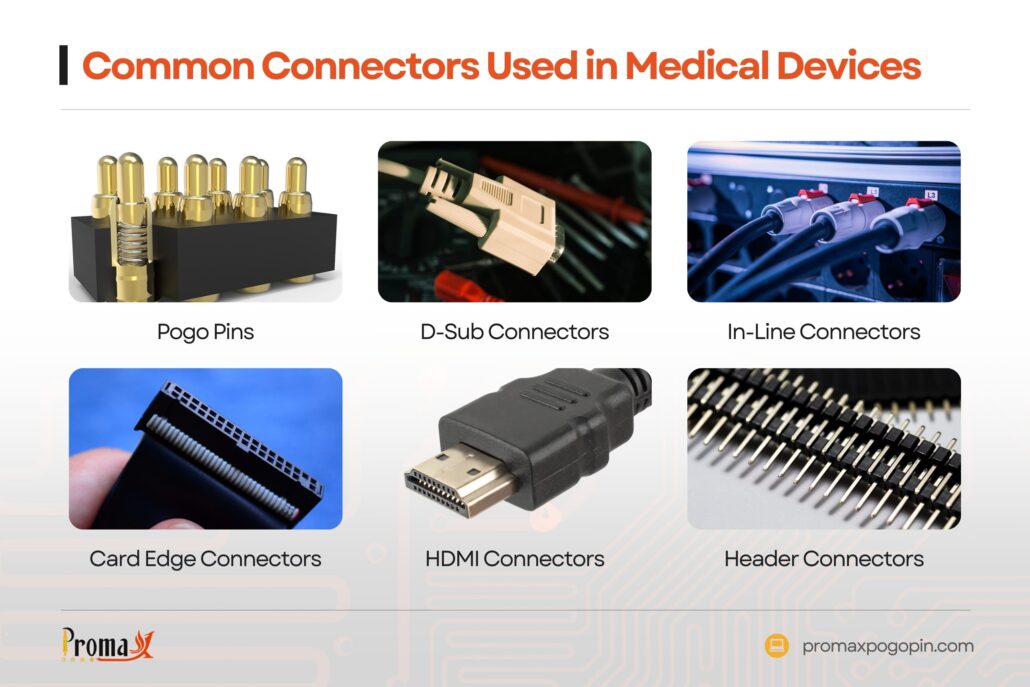

Of the various medical device connectors used in 2024, we’re going to focus on six common connector types: pogo pins, D-Sub connectors, in-line connectors, card edge connectors, HDMI connectors, and header connectors.

In the medical field, connectors are important components that allow for the safe and reliable operation of various medical equipment and devices. These medical electrical connectors ensure reliable communication between devices, enabling critical functions such as patient monitoring, diagnostics, and treatment delivery.

As the demand for advanced medical technologies continues to grow, understanding the common connector types used in medical applications becomes increasingly important. At Promax Pogo Pin, we want to make sure you’re in the know when it comes to medical device electrical connectors. This article explores six common connector types in the medical field, including their specific uses, benefits, and more!

Key Takeaways

- Pogo pins are user-friendly electrical connectors best for portable medical devices.

- D-Sub connectors are versatile and widely used in various medical applications.

- In-line medical device connectors provide reliable wire-to-wire connections in harsh environments.

- Card edge connectors stand out in multi-board solutions for high-performance medical equipment.

- HDMI connectors are essential for high-definition video transmission in imaging devices.

Common Connector Types in Medical Devices: Overview

To help you make an informed decision, we’ve outlined the most common connector types used in medical devices below.

| Connector Type | Uses | Benefits |

|---|---|---|

| Pogo Pins | Portable devices, e.g., hearing aids | Easy docking, compact, durable, compliant with regulations |

| D-Sub Connectors | Imaging systems and patient monitoring | Durable, versatile, reliable for power and data |

| In-Line Connectors | Wire-to-wire in tight spaces | Moisture-resistant, IP67 sealing, reliable in surgical use |

| Card Edge Connectors | Interconnections in MRI machines and monitors | High-density, space-saving, corrosion-resistant gold plating |

| HDMI Connectors | High-definition video in diagnostic tools | Supports HD video, waterproof options, wireless advancements |

| Header Connectors | Connects circuit boards in medical devices | Low resistance, high conductivity, designed for frequent use |

Pogo Pins

Pogo pins are a type of blind mate connector that have become popular in portable medical devices due to their ease of use and reliability, making them a robust connector solution for wearables and medical devices. These medical device connectors feature spring-loaded pins that maintain contact even during minor misalignment or vibrations, making them suitable for devices like hearing aids and wearable health monitors.

The design allows users to charge or dock their devices easily, which is important in settings where quick access to medical equipment is necessary. Pogo pins’ flexibility can be adapted to fit medical applications, including diagnostic tools and monitoring systems. Their small size and lightweight nature make them great for smaller medical devices where space is limited.

Advancements in pogo pin technology have led to improved durability and performance, ensuring these pins can handle the pressures of frequent use in demanding environments. Promax Pogo Pin is highly skilled in manufacturing pogo pins that meet the regulatory compliance of the medical industry at affordable prices. Try a free sample!

D-Sub Connectors

D-Sub connectors in medical applications are quite popular because of their durability and versatility. Often used in imaging systems, patient monitoring equipment, and laboratory devices, D-Sub connectors deliver reliable connections for both power and data transmission. These connectors are designed to meet strict regulatory compliance standards, ensuring they can operate safely within various medical environments.

D-Sub connectors come in multiple configurations, allowing them to accommodate different pin counts and signal types, and enabling the connector systems to support complex applications. Their durable design makes them suitable for high-vibration applications found in surgical environments or mobile medical units. D-Sub connectors are used in the medical field because they can be customized with features such as locking mechanisms to prevent accidental disconnections during important procedures where devices may not fail.

In-Line Connectors

In-line connectors work as an important solution for wire-to-wire connections within medical devices. An in-line connector may be necessary in applications with space constraints or where a direct connection between two cables is required. In-line connectors have a specific medical device design that is built to handle exposure to fluids and other environmental factors that may compromise connection integrity.

In laboratory settings or surgical environments where moisture is a concern, these specialized connectors for medical devices have sealing capabilities that can prevent corrosion and ensure reliable performance. Many medical devices require peak performance and compliance, and these connectors are often used because they utilize materials that meet IP67 sealing ratings. They can also be fully dustproof and resistant to temporary immersion in water, making them popular connector types used in the medical field for a variety of applications.

Card Edge Connectors

Card-edge connectors are often used and inserted directly into the edge of a printed circuit board (PCB), allowing for efficient signal transmission while minimizing space requirements. Card edge connectors are integral components of many complex medical devices, providing interconnections between circuit boards within equipment such as MRI machines and patient monitors.

The design of card edge connectors allows them to support high-density connections with numerous pins packed into a compact form factor. They usually feature gold plating on contact surfaces to improve conductivity and resist corrosion over time. Card edge connectors can support multiple mating cycles without too much wear, which makes them a fantastic solution for medical devices.

HDMI Connectors

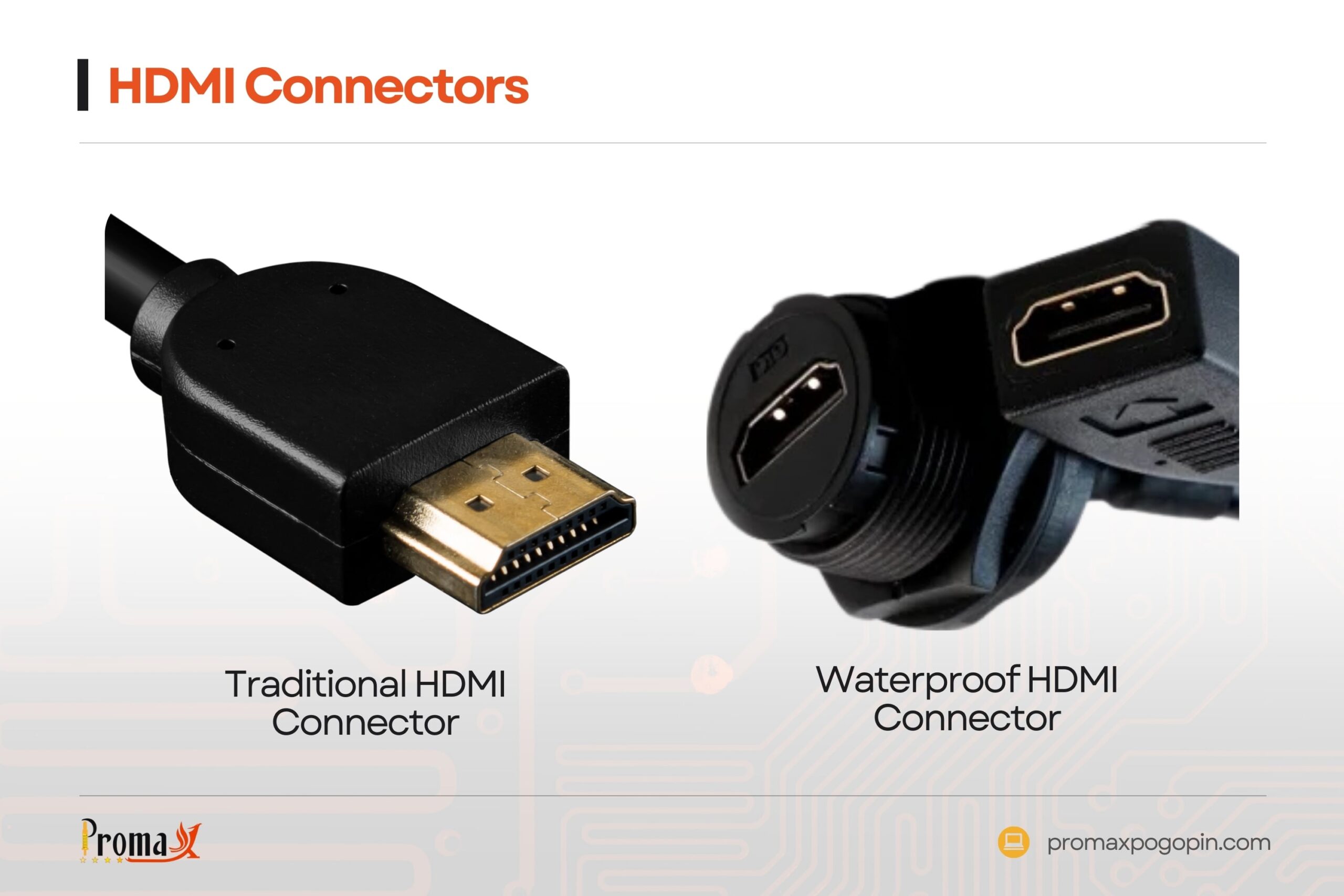

High-Definition Multimedia Interface (HDMI) connectors play a major role in modern medical imaging systems. HDMI connectors are used to enable high-quality video transmission between devices. D-Sub connectors and HDMI connectors are quite similar in this way.

Traditional HDMI connector designs may be found in ultrasound machines, endoscopy systems, and other diagnostic tools that require clear image output for accurate analysis. These HDMI connector designs also need to handle vibrations, shocks, and moisture.

In addition to standard HDMI configurations, specialized waterproof HDMI connectors use innovative technology, and are available for use in surgical environments where exposure to liquids is likely. These connectors ensure that high-definition video signals remain uninterrupted while maintaining the safety standards required in the medical field. Moreover, advancements such as wireless transmission capabilities will further the growth and adaptability of HDMI technology and its uses across various medical technologies.

Header Connectors

Headers are the connector heads used in all multi-board solutions. They facilitate connections between different circuit boards found in complex systems like X-ray machines or cardiac monitors. Usually paired with flexible ribbon cables, header connectors provide a reliable method of transferring power and data across multiple boards.

The design of header connectors often includes high-conductivity materials that ensure low resistance and optimal performance, even under demanding conditions. With features like gold plating on contact points to prevent corrosion and improve durability, these connectors are well-suited for frequent mating cycles encountered in modern medical device designs.

Promax Pogo Pin: Cost-Effective Quality Pogo Pins

Among the six common connector types discussed, pogo pins stand out as a cost-effective solution that meets the demands of many modern portable medical applications. With their user-friendly design and durable performance features, pogo pins demonstrate how innovative connector solutions can improve functionality while maintaining compliance with industry standards.

If you’re looking for reliable connector solutions tailored specifically to the medical field, contact Promax Pogo Pin. We’ll introduce you to cost-effective pogo pins designed for optimal performance across diverse electrical medical devices. Reach out today to discover how these advanced connector technologies for medical use can support your next project!

Common Connector Types Used in Medical Devices FAQs

What is the most common connector used today?

The USB connector is the most common connector used today; it’s widely used in both consumer electronics and medical devices. USB connectors are also often used in computers as an expansion as the industry accelerates. The e-pin male connector is another common type, often used in computers as well as various other applications. In the medical field, connectors with high durability are essential for reliable performance. Specifying electronic connectors for medical technology is not always straightforward, as medical devices must meet strict safety and functionality standards.

How many connected medical devices are there?

Recent estimates show that there are millions of connected medical devices worldwide, highlighting the growing trend in health care technology. These devices must meet stringent regulatory requirements to ensure safety and efficacy in patient care. The increasing number of connectors in medical equipment shows the importance of reliable connections for device functionality.

What are the types of connected medical devices?

Connected medical devices may include wearable health monitors, telemedicine equipment, diagnostic equipment, imaging devices, and patient monitoring systems. Considerations and quality standards for medical device connectors in the medical field are also essential. These connectors must ensure compatibility, durability, and compliance with industry standards to maintain device performance.

Back to top: 2024 Common Connector Types Used in Medical Devices

Over 15 Years of Expertise

Over 15 Years of Expertise FREE samples provided to ensure product satisfaction

FREE samples provided to ensure product satisfaction Rapid Turnaround: Mass Production Complete in 15 - 20 Days

Rapid Turnaround: Mass Production Complete in 15 - 20 Days