Leading Manufacturer of Magnetic Pogo Pin Connectors!

Magnetic Pogo Pin Connectors are an essential component of many electrical appliances and products. They are sought after, especially due to their durability and resilience. Because they’re so important, you can’t afford to compromise on their quality!

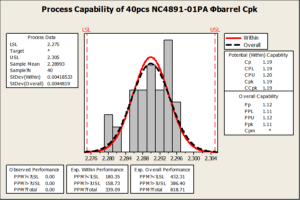

We manufacture and supply top-tier Magnetic Pogo Pin Connectors that meet the highest global standards.According to the FPY (First Pass Yield), which is a reliable quality index, our Magnetic Pogo Pin Connectors are simply unmatched. We ensure>95% Sample FPY and >99% mass production FPY. Our Magnetic Pogo Pin Connectors are excellent in terms of precision, smart design, and manufacturing technologies.

Timely and Safe Delivery

Leave your requirements and let Dongguan Promax handle the rest.

24/7 Online Support

Dongguan Promax is always here to support your business.

Cost-Effective

Get better shipping rates to reduce your costs.

Magnetic Pogo Pin Connectors

Our Partner Said

“Dongguan Promax has helped us with many field issues. I have to say their engineers are so experienced and can quickly help me solve the problem. The problem was high temperature caused by excessive current.”

Paul Jelloy

Buyer from the UK

How about our products’ Cpk?

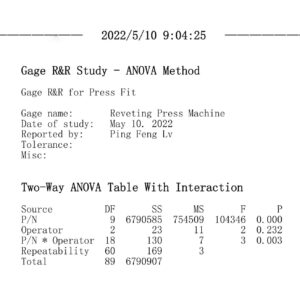

Gage R&R (ANOVA) for Press Fit

FAQ

Pogo Connector, also called Spring Loaded Connector, Spring Connector, Electrical Contact Connector, or Connector Contact Pin. A pogo connector consists of ≥2 single pogo pins, as well as housing and cap if necessary.Based on customers’ various requirements, of Single pogo pin, T-pin, Ball, or coaxial is also designed as the fourth part, besides the plunger, spring, and barrel.The pogo pin is assembled and then the pogo pin housing component is added to assemble the pogo connector.Pogo connector is widely used in modern electronic technology as a connection. At present, the connector is widely used in consumer electronics, health science and technology, smart cars, new energy, chip testing, and other fields. Every pogo connector is highly durable, with a life cycle of 10,000~100,000 times.

Due to customers needing different applications, different design concepts are also required.These include Bias Tail, Back Drilling, Ball Type, T-pin type, or Coaxial.Of these 4 designs, designs of T-pin/Ball/Coaxial can meet the requirement of high current, up to 15A or upper, and its impedance is <30mΩ.Bias Tail can greatly improve the stability of the Spring Loaded Pin, the current is <3A, and its impedance is <30mΩ.

- Back Drilling can greatly save design space, making it suitable for designs needing minimal space, as the current is <1A, and its impedance is <200mΩ.

- The inclined plane will be in closely contacted with the plunger, effectively maintaining the impedance stability, and impedance < 30 mΩ, which can stabilize the large current.

- The ball will uniformly exert pressure on the plunger to ensure stable impedance and smooth sliding of the plunger.

- Free Height: no load height, full extension height of spring

- Working Height: the ideal load height for spring

- Maximum Load Height: the maximum load height of the spring, usually, contacting the end of the barrel

- Pogo Connector which is very stable after mounting onto the housing due to the barb on the barrel

- Stopper on the bottom of the spring-loaded pin, which fixes very strongly into the housing too

- When automatically matching equipment, such a pogo pin connector is usually praised by users

- Space-saving

- Because of large tolerance, great freedom when using the pogo connector

- Can be assembled quickly and is very flexible

- Very stable performance of power supply, which minimizes the safety risks

Factors that influence the service life of pogo connector:Factor 1: Friction and corrosive environment of pogo pin in application

- When a pogo pin is working in the application, the opening and closing will produce friction along with various corrosive substances in the working environment. In this way, the use of the pogo pin will depreciate over time.

Factor 2: Plug-out force of pogo connector in application

- Under normal conditions, the insertion and extraction times of a pogo pin will exceed 10000. Hence, the insertion and extraction force of a pogo pin is a key factor in the service life of the connector. But the insertion and removal force is difficult to control, a small force makes it easy to fall, and a large force makes it easy to damage. The core team of Dongguan Promax solved this problem to a large extent, by increasing the maximum number of pogo connector insertions and extractions to 100,000 times.

Factor 3: Resistance in the use of a pogo connector

- Usually, the resistance of a pogo connector is determined by the material and coating. At present, most materials of pogo pins are brass, so the key to prolonging the service life of pogo pins is solid electroplating. Dongguan Promax adopts a special electroplating method so that the connector maintains a stable resistance value. This prolongs the service life of the Pogo connector.

During process flow, we set up 5 QC workstations to ensure product quality, and 1 IPQC to line tour each workstation. In this way, we can ensure incoming material arrives properly at station 02, and semi-finished goods are produced well at station 04.This can ensure the preloading of a single pin correctly on station 09, as well as cementing spring force, impedance, and function adequately on station 12.We also make sure product cosmetic is handled well on station 13.Hence we maximize FPY (first pass yield) of the sample, which is more than 95%, while the FPY of mass production is more than 99%, and the RTY (Rolled-throughput Yield) is more than 90%.

Like spring-loaded pins, pogo connectors are widely used in all kinds of fields, for example, consumer electronics, wireless communication equipment, 5G, new energy, POS, medical, industry, and many others.These magnetic connectors play various roles from the power supply and equipment to 5G RF signal transmission. These roles include:

- TWS charging box

- Two-In-One Laptop

- Electric Car charging system

- Smart Glasses (because of the minuscule space they take up, stable power supply transmission, high durability, and long-term life cycle)

- Handheld device charger, for example, Phone, Bar code reader, Laptop

- Warehouse Robot

- Intelligent Speaker

- Smart Watch, Smart bracelet

The packaging consists of tape and reel, tray, tube, box, and PE bag. Dongguan Promax has several automatic packaging machines, which greatly improve the packaging speed of the Pogo connector.Because the speed of our automatic packaging machines is 5 times that of manual packaging, we have far superior production efficiency and supply speed here at Dongguan Promax.